Chemical plating solution for preparing composite coating resistant to fretting damage and chemical plating method thereof

A technology of chemical plating solution and composite coating, which is applied in the direction of liquid chemical plating, coating, metal material coating technology, etc., can solve the problems of not having the function of anti-friction and wear resistance, and achieve good resistance to fretting damage and corrosion , Strong practicability and stable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

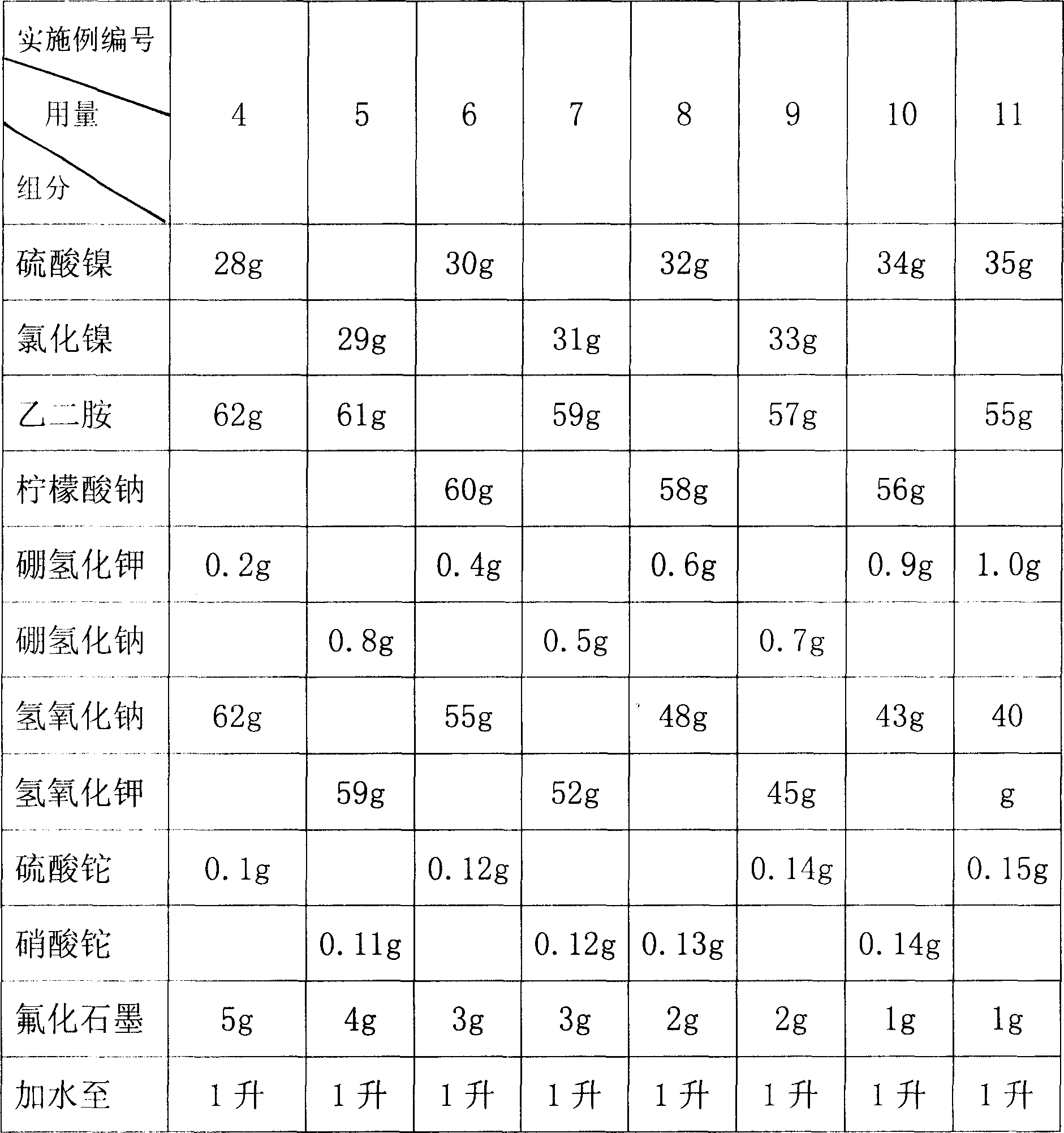

Examples

Embodiment 1

[0033] A kind of electroless plating solution for preparing anti-fretting friction damage composite coating, the composition and content of every 1 liter (L) of chemical plating solution are:

[0034] Nickel Sulfate NiSO 4 ·7H 2 O 28g,

[0035] Ethylenediamine NH 2 CH 2 CH 2 NH 2 55g,

[0036] Sodium borohydride (NaBH) 4 0.2g,

[0037] Sodium hydroxide NaOH 40g,

[0038] Thallium nitrate TlNO 3 0.1g,

[0039] Graphite fluoride (CF) n 1g.

[0040] The preparation method of above-mentioned electroless plating solution is:

[0041] 1. Weigh the metered nickel sulfate (NiSO 4 ·7H 2 O), ethylenediamine (NH 2 CH 2 CH 2 NH 2 ), sodium borohydride [(NaBH) 4 ], sodium hydroxide (NaOH), thallium nitrate (TlNO 3 ), respectively dissolved with a small amount of water;

[0042] 2. Weigh the metered graphite fluoride [(CF) n ] (particle diameter is 1~5 μ m), make hydrophilic and positively charged surface treatment with catio...

Embodiment 2

[0047] A kind of electroless plating solution for preparing anti-fretting friction damage composite coating, the composition and content of every 1 liter (L) of chemical plating solution are: nickel chloride (NiCl 2 ·6H 2 O) 32g, sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O) 60g, potassium borohydride (KBH) 0.5g, potassium hydroxide (KOH) 50g, thallium nitrate (TlNO 3 )0.12g, graphite fluoride (CF) n(particle size 1-5μm) 2g, add water (preferably distilled water or deionized water) to 1 liter. The immersion plating temperature is 85°C, the pH value is 13, and the plating time is 10 to 60 minutes. Others are the same as in Example 1, omitted.

Embodiment 3

[0049] A kind of electroless plating solution for preparing anti-fretting friction damage composite coating, the composition and content of every 1 liter (L) of chemical plating solution are: nickel sulfate (NiSO 4 ·7H 2 O) 35g, sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O) 62g, potassium borohydride (KBH) 1.0g, potassium hydroxide (KOH) 62g, thallium nitrate (TlNO 3 )0.15g, graphite fluoride (CF) n (particle size 1-5μm) 5g, add water (preferably distilled water or deionized water) to 1 liter. The immersion plating temperature is 88°C, the pH value is 14, and the plating time is 10 to 60 minutes. Others are the same as in Example 1, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com