Coating material and preparation method thereof

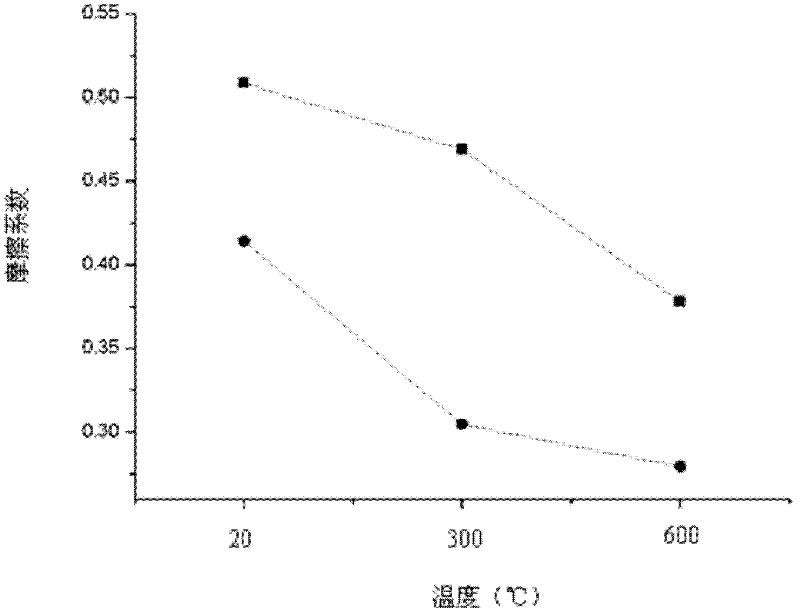

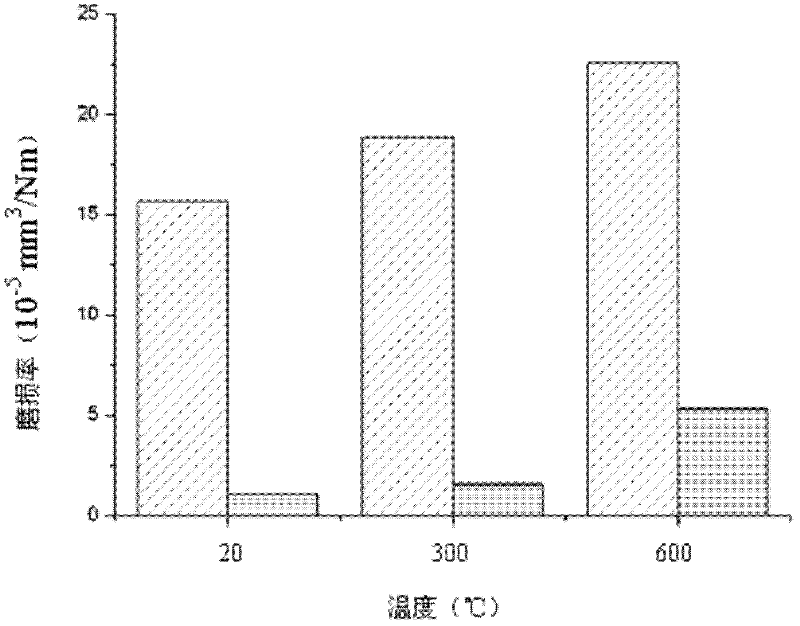

A coating material and coating technology, applied in the field of alloys, can solve problems such as wear, aggravated coupling, poor friction compatibility and self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a method for preparing a coating material. Take 14-17.5 parts by weight of nickel, 3-3.5 parts by weight of chromium, 49-52.5 parts by weight of chromium carbide, and 25-30 parts by weight of tungsten disulfide, and pulverize After mixing with adhesive, coating and drying, laser cladding under the protection of inert gas can be obtained; the inert gas can be nitrogen or argon.

[0043] In some embodiments provided by the present invention, in the preparation method of the coating material provided by the present invention, the binder is methyl cellulose or phenolic resin.

[0044] In some other embodiments provided by the present invention, in the preparation method of the coating material provided by the present invention, the adhesive is 2123 phenolic resin, which is formed by polycondensation of phenol and formaldehyde under the action of an acidic catalyst.

[0045] In some embodiments provided by the present invention, in the preparation method...

Embodiment 1

[0059] Take 14 parts by weight of nickel, 3.2 parts by weight of chromium, 51 parts by weight of chromium carbide, and 25 parts by weight of tungsten disulfide, and pulverize them to obtain a powder mixture. Use 2123 phenolic resin as binder, mix with the above powder mixture, coat on the surface of austenitic stainless steel, bake and dry.

[0060] Inert gas is blown to the molten pool to avoid surface oxidation of the molten pool, and a single-channel CO with a power of 1.0kW is used 2 Laser irradiation coating, that is. The rectangular spot size of the laser is 6mm×3mm, and the scanning speed is 5mm / s. After testing, the prepared austenitic stainless steel coating mainly includes Cr 7 C 3 , γ-(Fe, Ni), (Cr, W)C complex carbides and a small amount of WS 2 and CrS.

Embodiment 2

[0062] Take 17.5 parts by weight of nickel, 3.5 parts by weight of chromium, 49 parts by weight of chromium carbide, and 30 parts by weight of tungsten disulfide, and pulverize them to obtain a powder mixture. Use methyl cellulose as binder, mix with the above powder mixture, coat on the surface of austenitic stainless steel, bake and dry.

[0063] Blow inert gas to the molten pool to avoid oxidation of the surface of the molten pool, and use multi-channel overlapping CO with a power of 1.5kW 2 Laser irradiation coating, that is. The rectangular spot size of the laser is 6mm×3mm, the scanning speed is 4mm / s, and the overlapping rate of the multi-channel overlapping laser is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

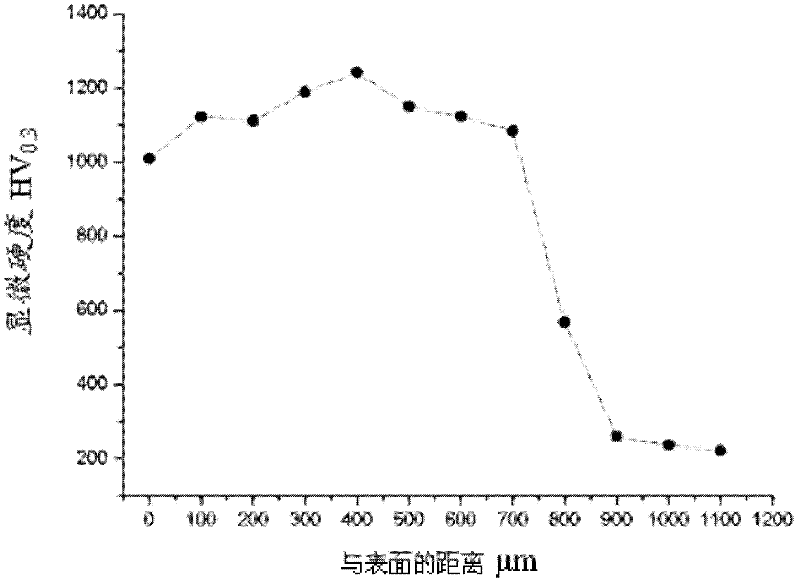

| microhardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com