Normal temperature water-based antirust cleaning agent

A cleaning agent, water-based technology, applied in the field of microemulsion water-based normal temperature rust-proof cleaning agent, can solve the problems of limited use range and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

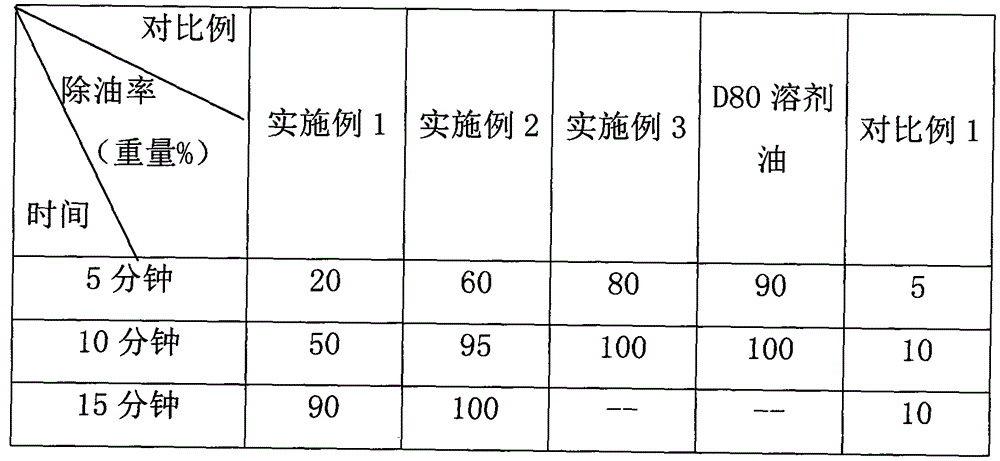

Examples

Embodiment 1

[0016] Example 1, the formula consists of: 5 parts of D-limonene; 1 part of diethylene glycol butyl ether; 1 part of fatty alcohol polyoxyethylene ether; 1 part of fatty acid ester ethoxylate sulfonate; 0.5 parts of sodium citrate 0.1 part of sodium silicate; 0.1 part of sodium hydroxide; 0.1 part of undecane dibasic acid triethanolamine salt; 91 parts of water.

Embodiment 2

[0017] Example 2, the formula consists of: 15 parts of D-limonene; 5 parts of diethylene glycol butyl ether; 5 parts of fatty alcohol polyoxyethylene ether; 5 parts of fatty acid ester ethoxylate sulfonate; 1.5 parts of sodium citrate 0.5 parts of sodium silicate; 0.5 parts of sodium hydroxide; 0.5 parts of undecane dibasic acid triethanolamine salt; 67 parts of water.

Embodiment 3

[0018] Example 3, the formula consists of: 25 parts of D-limonene; 10 parts of diethylene glycol butyl ether; 10 parts of fatty alcohol polyoxyethylene ether; 10 parts of fatty acid ester ethoxylate sulfonate; 3 parts of sodium citrate 1 part; sodium silicate 1 part; sodium hydroxide 1 part; undecane dibasic acid triethanolamine salt 1 part; water 39 parts.

[0019] Preparation Process:

[0020] Prepare the raw materials according to the above formula, mix and stir 15 parts of D-limonene, 5 parts of diethylene glycol butyl ether, 5 parts of fatty acid polyoxyethylene ether, and 5 parts of fatty acid ester ethoxylate sulfonate. Inject 67 parts of water slowly, stir until the solution is clear and transparent, then add 1.5 parts of sodium citrate, 0.5 parts of sodium silicate, 0.5 parts of sodium hydroxide, and 0.5 parts of undecyl triethanolamine salt, and continue stirring until the solution is clear and transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com