High-temperature and low-temperature expansion energy-saving nitrogen production device and nitrogen production method

A double-expansion, energy-saving technology, applied in refrigeration and liquefaction, liquefaction, solidification, etc., can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

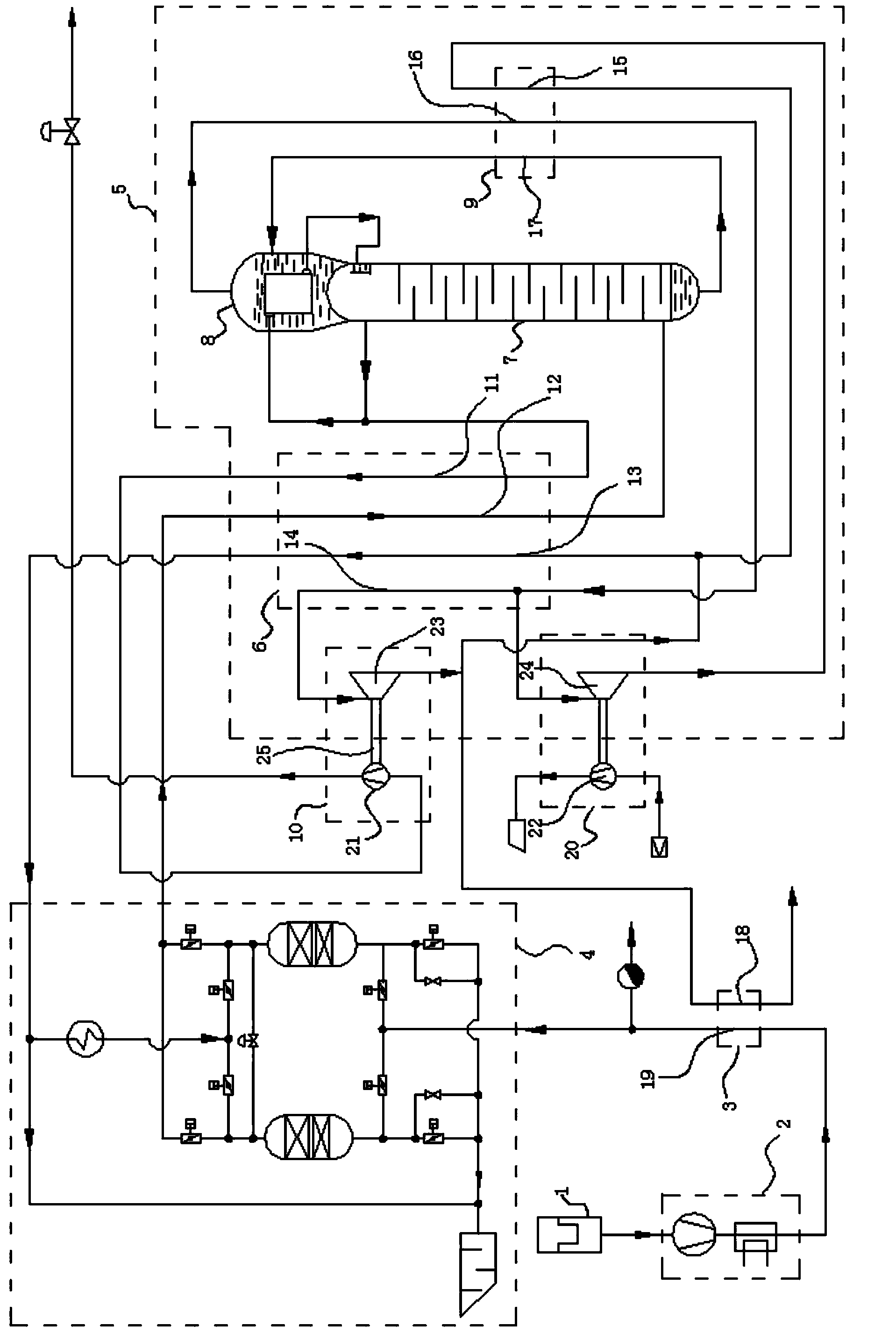

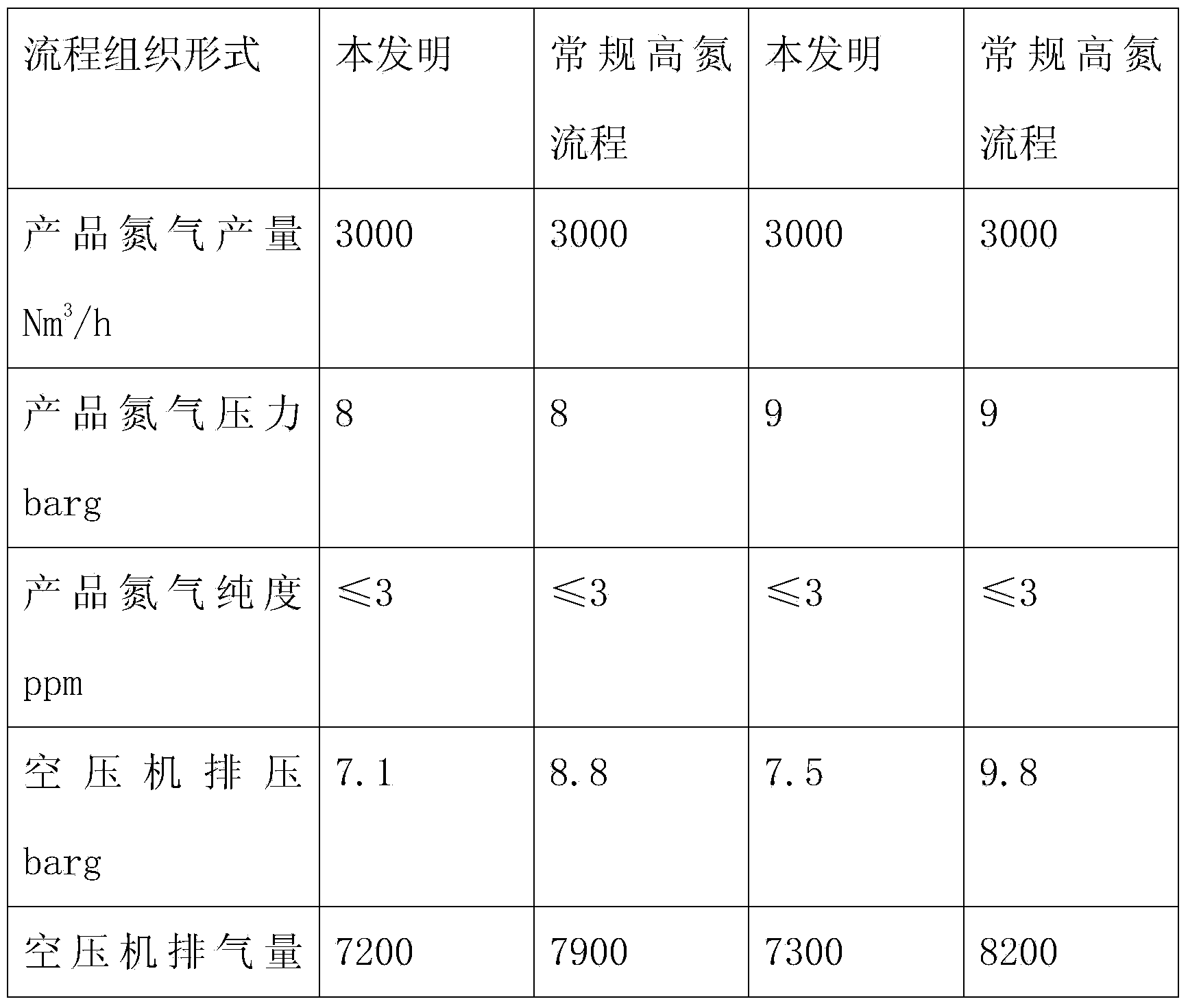

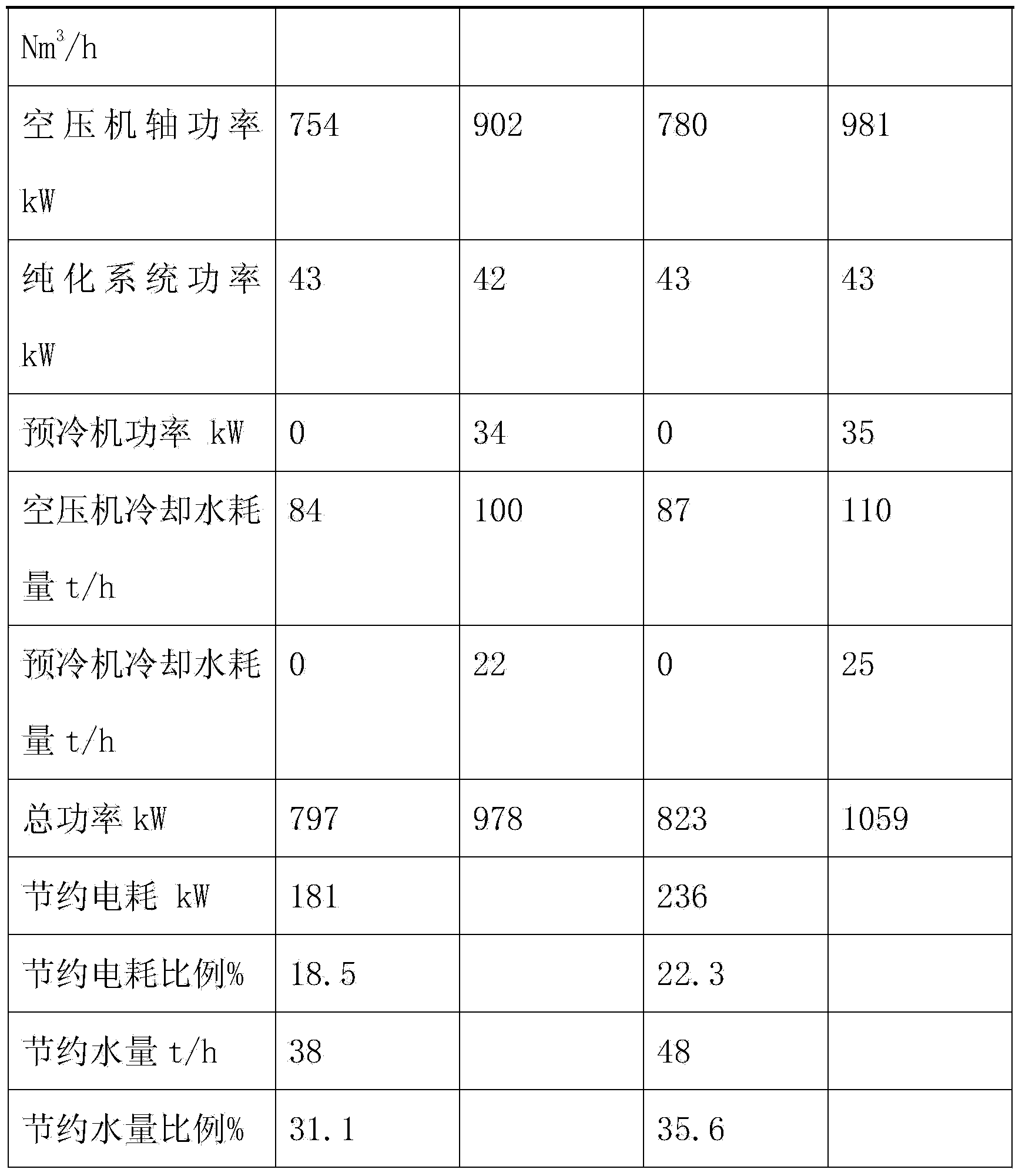

[0024] High and low temperature dual-expansion energy-saving nitrogen generators, such as figure 1 As shown, the arrow in the figure indicates the flow direction of the stream, including the filter 1, the air compressor 2 connected to the filter 1 through pipelines, the pre-cooling heat exchanger 3 connected to the air compressor 2 through pipelines, and the pre-cooling heat exchanger Heater 3 is connected to purification device 4 by pipeline, and cold box 5 is connected to purification device 4 by pipeline. Cold box 5 includes main heat exchanger 6, rectification tower 7, condensation evaporator 8, subcooler 9, Pressure turbo expander 10, low temperature expander 20.

[0025] The main heat exchanger 6 comprises a first pipeline 11, a second pipeline 12, a third pipeline 13, a fourth pipeline 14 ( figure 1 From right to left in the middle are the first pipeline 11, the second pipeline 12, the third pipeline 13 and the fourth pipeline 14). Subcooler 9 includes the fifth pipel...

Embodiment 2

[0039] The high and low temperature dual expansion energy-saving nitrogen production method comprises the following steps:

[0040] a. Filter the raw material air through the filter 1, and the air after filtering out impurities enters the air compressor 2, and is compressed to 7bar to 10bar in the air compressor 2. In this embodiment, the air is compressed to 8bar in the air compressor 2 , the air compressed to 8 bar enters the pre-cooling heat exchanger 3, and after the air is cooled and separated from free water in the pre-cooling heat exchanger 3, the air enters the purification device 4; the moisture and carbon dioxide in the air in the purification device 4 To be cleared, to get purified air.

[0041] b. the purified air obtained in step a is delivered to the second pipeline 12 of the main heat exchanger 6 in the cold box 5 for cooling, and the air cooled to a temperature of 104K to 112K enters the rectification column 7 from the inlet Distillation column 7 carries out r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com