Energy-saving comprehensive chemical wastewater deep treatment system and treatment method thereof

A technology for chemical wastewater treatment system, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of high manufacturing and operating costs, uneconomical, high salt content, and achieve extremely high The effect of less chemical phenomenon, high degree of automation and high burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

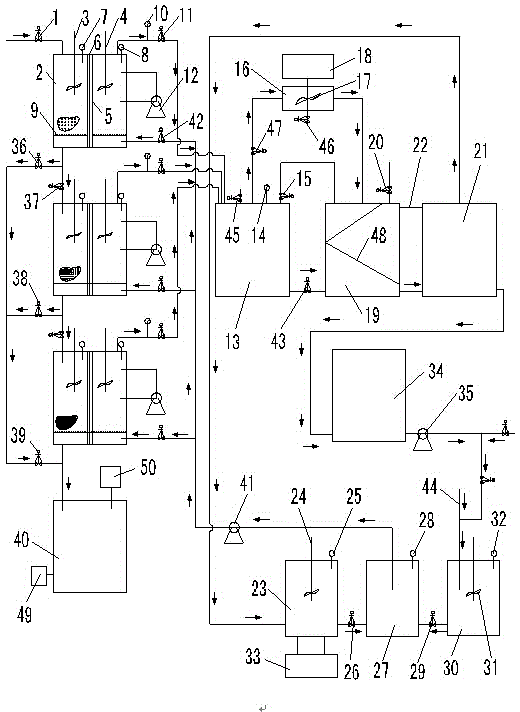

[0051] The high-efficiency and energy-saving comprehensive chemical wastewater treatment system of the present invention mainly includes a forward osmosis membrane concentration device, a mother liquid incinerator 40 and an osmotic energy utilization device, and each device is connected in sequence through pipelines. The specific structure of each device is as figure 1 shown.

[0052] Forward osmosis membrane concentration device, including at least one FO membrane closed exchange box 2 ( figure 1 There are 3 levels), drawing liquid recycling device and clear water recycling device.

[0053] A membrane frame 5 is arranged in the middle of the single-stage FO membrane airtight exchange box 2 , and a membrane element 6 is arranged in the membrane frame 5 . The membrane frame 5 divides the FO membrane closed exchange box 2 into two parts: the left mother liquor area (comprehensive chemical wastewater area) and the right draw liquid area. The two areas are completely independent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com