Copper pour use aluminum nitride substrate pretreatment method

An aluminum nitride substrate and pretreatment technology, applied in the field of DBC board manufacturing, can solve the problems of low peel strength, high porosity, poor temperature cycle resistance, etc., to promote uniform growth, reduce process conditions, and improve wetting effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

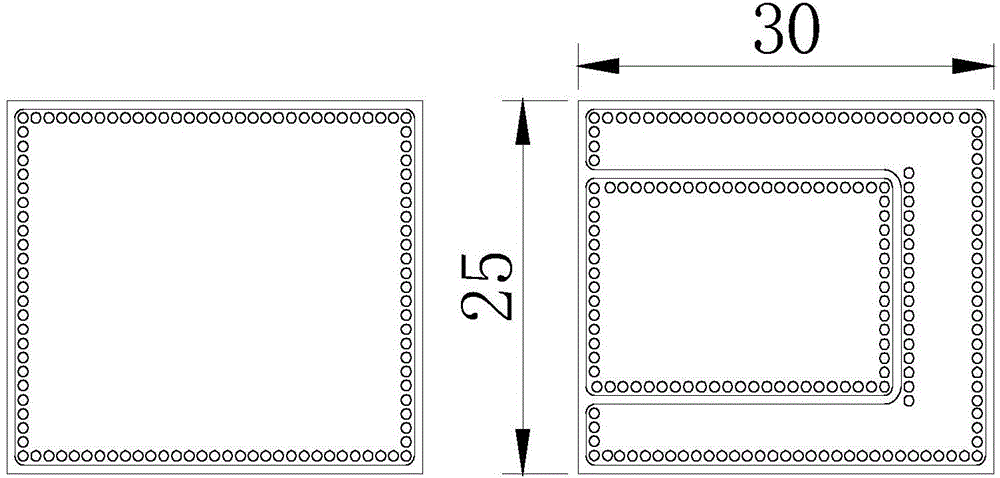

[0035] Example 1, such as figure 2 The aluminum nitride DBC structure is shown, the ceramic thickness is 0.635mm, and the length and width are 76.2mm.

[0036] Put the self-made aluminum nitride substrate into the degreasing solution and ultrasonically clean it for 10 minutes, and the surface is clean and free of oil.

[0037] The aluminum nitride substrate was placed in a NaOH solution with a concentration of 0.1mol / L for activation, and ultrasonic treatment was used for 5 minutes, ultrasonic power was 60%, and water temperature was 60°C.

[0038] A transition layer was prepared on the surface of the activated aluminum nitride substrate by dipping method, the molar content of manganese nitrate in the transition layer was 0.01mol / L, copper sulfate was 0.01mol / L, and the additive sodium citrate was 0.005mol / L.

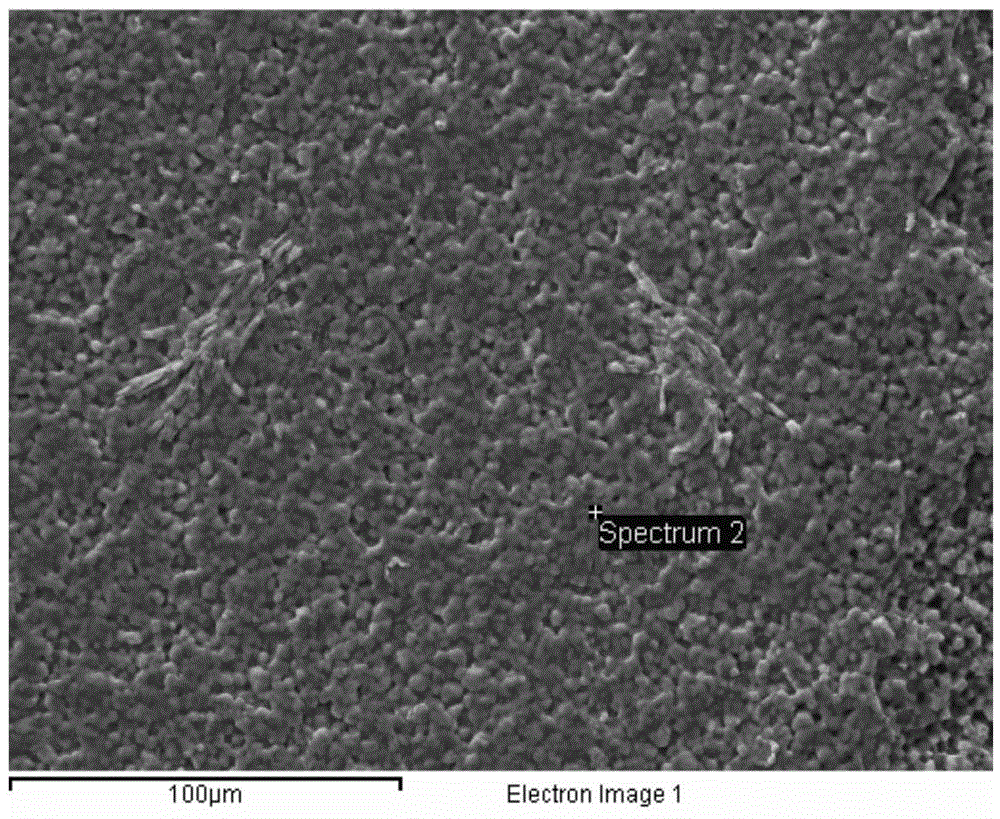

[0039] The aluminum nitride substrate with the prepared transition layer needs to be pretreated at 300°C and cooled naturally, so that the transition layer forms a...

example 2

[0041] Example two, such as figure 2 The aluminum nitride DBC structure is shown, the ceramic thickness is 0.635mm, and the length and width are 76.2mm. Put the self-made aluminum nitride substrate into the degreasing solution and ultrasonically clean it for 10 minutes, and the surface is clean and free of oil.

[0042] The aluminum nitride substrate was placed in a NaOH solution with a concentration of 0.1mol / L for activation, and ultrasonic treatment was used for 5 minutes, ultrasonic power was 60%, and water temperature was 60°C.

[0043] Prepare a transition layer on the surface of the activated aluminum nitride substrate by dipping method. The molar content of manganese nitrate in the transition layer is 0.01mol / L, copper sulfate is 0.005mol / L, calcium nitrate and aluminum sulfate are 0.001mol / L each, additives Sodium citrate 0.005mol / L.

[0044] The aluminum nitride substrate with the prepared transition layer needs to be pretreated at 300°C and cooled naturally, so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com