Preparation method for distilled bitter buckwheat wine

A technology for distilling wine and tartary buckwheat, applied in the field of winemaking, can solve problems such as complex overall process, and achieve the effects of simple preparation process, improved utilization rate, and promotion of tartary buckwheat industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

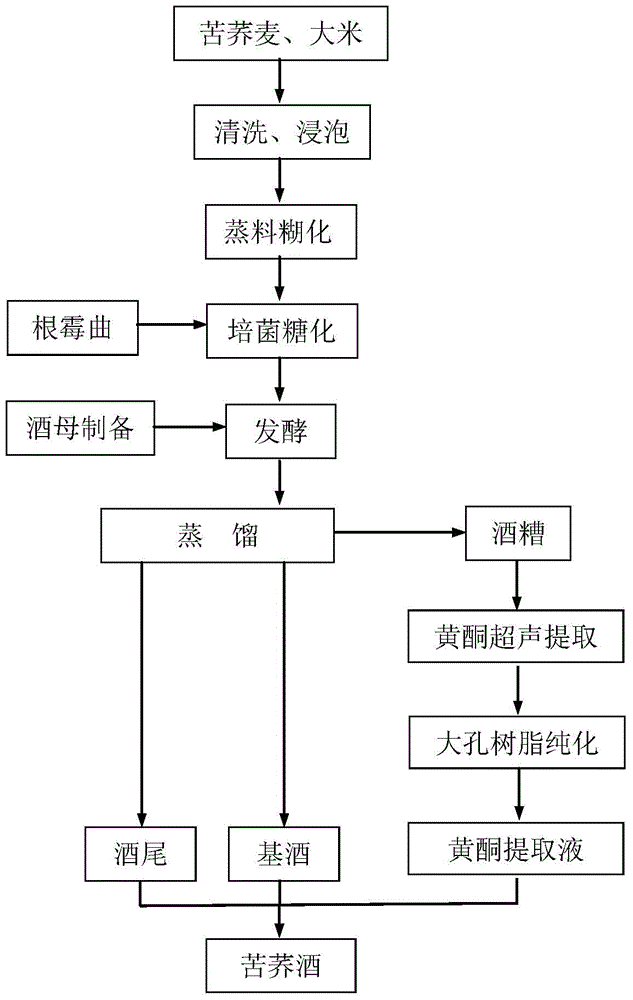

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the preparation method of tartary buckwheat distilled wine

[0038] 1. Raw materials (by mass percentage):

[0039] 20% tartary buckwheat, requiring full grains, no mildew, no moths;

[0040] 80% rice, requiring smooth color, no impurities, no disease spots;

[0041] 2. Cleaning and soaking:

[0042] Mix tartary buckwheat and rice, rinse until the drenched water is not cloudy, add water and soak for 6 hours;

[0043] 3. Gelatinization of steamed material:

[0044] Mix fully water-absorbed tartary buckwheat and rice evenly, steam and gelatinize under normal pressure for 30 minutes, and let it cool for later use;

[0045] 4. Bacteria saccharification:

[0046] Put tartary buckwheat and rice cooled to room temperature in a pre-cleaned and sterilized saccharification tank, mix 1.0% of the raw material weight into rhizopus koji, seal with gauze, and saccharify at 30°C for 24 hours;

[0047] 5. Preparation of distiller's mother:

[0048] Dissolve 1 g of 0...

Embodiment 2

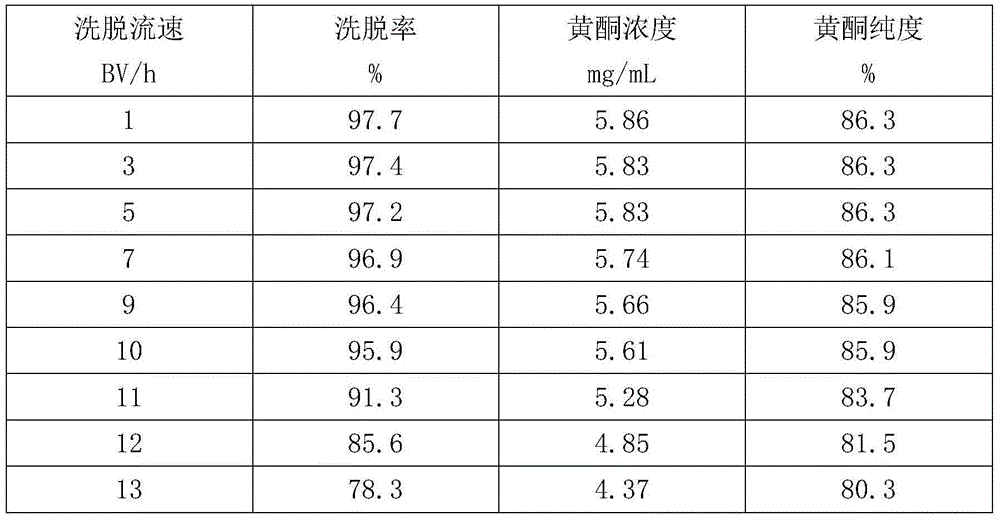

[0061]Example 2: Effects of different elution flow rates on the extraction effect of flavonoids

[0062] The flavonoids ultrasonically extracted from tartary buckwheat distiller's grains are evaporated and concentrated, then reconstituted with deionized water, and then adsorbed through the AB-8 macroporous resin column at a flow rate of 2BV / h. After the adsorption is completed, rinse the resin column with an appropriate amount of deionized water . After the effluent is clarified, use 60% (V) base wine as eluent to recover flavonoids. In order to investigate the effect of different elution flow rates on the extraction effect of flavonoids, elution tests at different flow rates were carried out, and the results are shown in Table 2. As can be seen from Table 2, when the elution flow rate is at 1-10BV / h, the elution rate of base wine (60% (V)) to flavonoids remains above 95%, and the obtained flavonoids have a purity of about 86%; As the elution flow rate gradually increased fr...

Embodiment 3

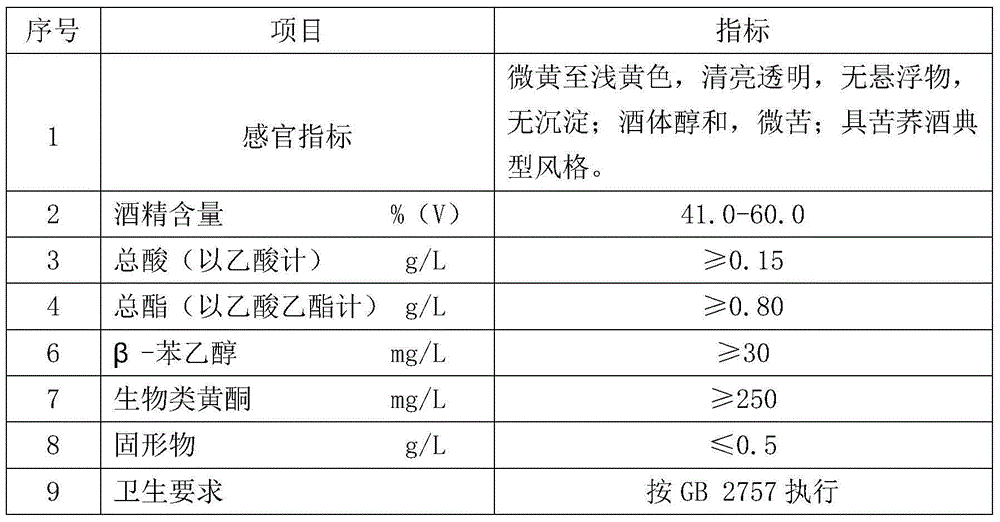

[0065] Embodiment 3: the modulation of tartary buckwheat distilled wine

[0066] According to different flavonoid content requirements, base wine (63% (V), flavonoid content is 0mg / L), flavonoid extract (alcohol content 60% (V), flavonoid content is 5610mg / L) and wine tail (alcohol content 20mg / L) % (V), the flavonoid content is 0mg / L) adjusted to the distilled wine rich in tartary buckwheat flavonoids of 55% (V). See Table 3 for the sensory evaluation and physical and chemical determination results of the obtained tartary buckwheat distilled wine samples. It can be known from Table 3 that when the flavonoid content in the wine is 400-600 mg / L, the tartary buckwheat wine has a mellow taste and moderate bitterness. For adults, the general dosage of flavonoids to achieve health effects is 50 mg per day. According to this calculation, drinking about 100 mL of tartary buckwheat wine a day can achieve health effects.

[0067] Table 3 Preparation of 55% (V) Tartary Buckwheat Disti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com