Method for preparing mannan-oligosaccharide through enzymolysis of fine konjak powder

A technology of oligomeric mannose and konjac fine powder, which is applied in the field of bioengineering, can solve the problems of high substrate viscosity, high concentration production, high cost of enzyme production and use, and low catalytic efficiency of key enzymes, and achieve production and use The effect of low cost, short production cycle, and simple separation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

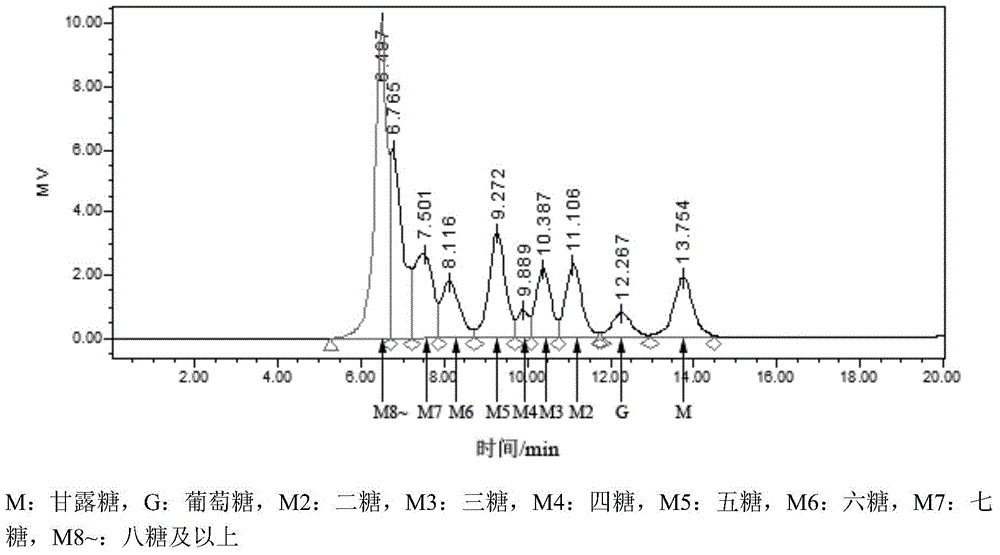

[0023] Embodiment 3 ultrafiltration method prepares konjac fine powder mannose oligosaccharide

[0024] Carry out the enzymolysis reaction with optimized reaction conditions. After the reaction, inactivate the enzyme in boiling water and cool it down. The enzymolysis solution is centrifuged through a 0.45μm water film and then transferred to an ultrafiltration device. The molecular weight cut-off is 2000kDa under a pressure of 0.2MPa. The ultrafiltration membrane is used for ultrafiltration, and the oligosaccharides with a molecular weight cutoff of <2000 are collected, and the ultrafiltration permeate is collected. The sugar solution was concentrated by a rotary evaporator and then freeze-dried, and samples were taken for high-performance liquid chromatography (HPLC) to detect the composition of the enzymatic hydrolysis product.

[0025] Embodiment 4 konjaku powder hydrolyzate component analysis

[0026] Weigh oligomannose freeze-dried powder and dissolve to a concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com