A hazardous waste incineration feeding device

A hazardous waste and feeding device technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as economic losses, increased operating costs, loose and uneven states, etc., achieve stable and uniform feeding, and save manpower , the effect of controlling the combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

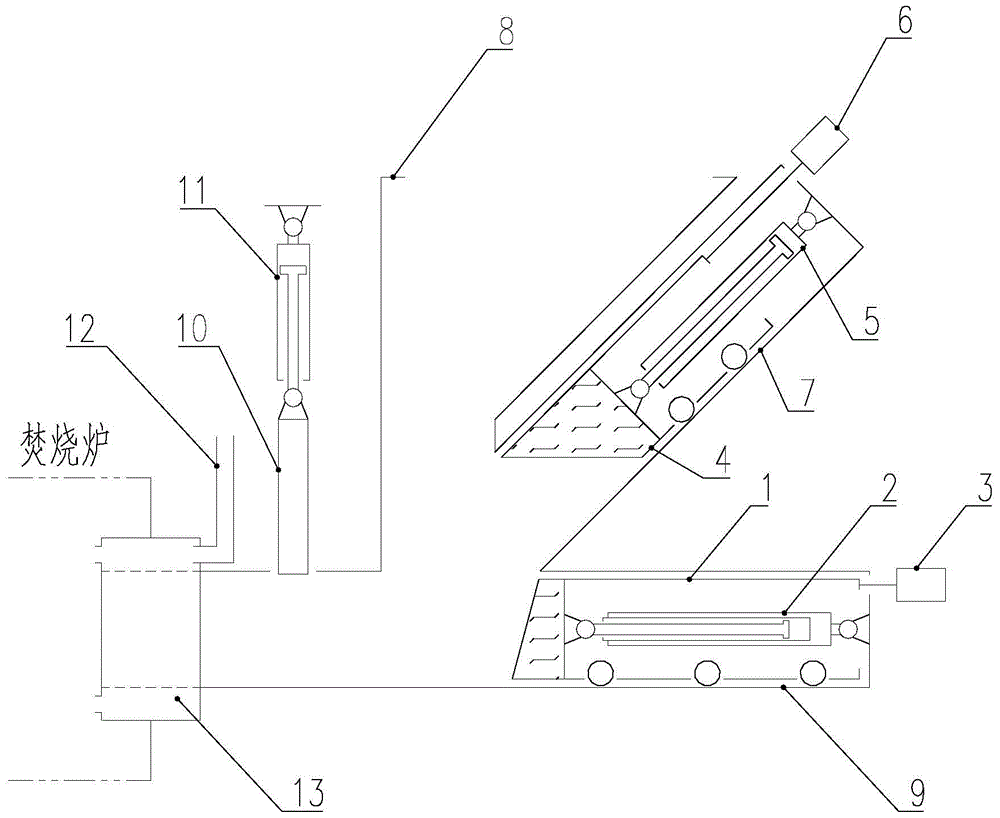

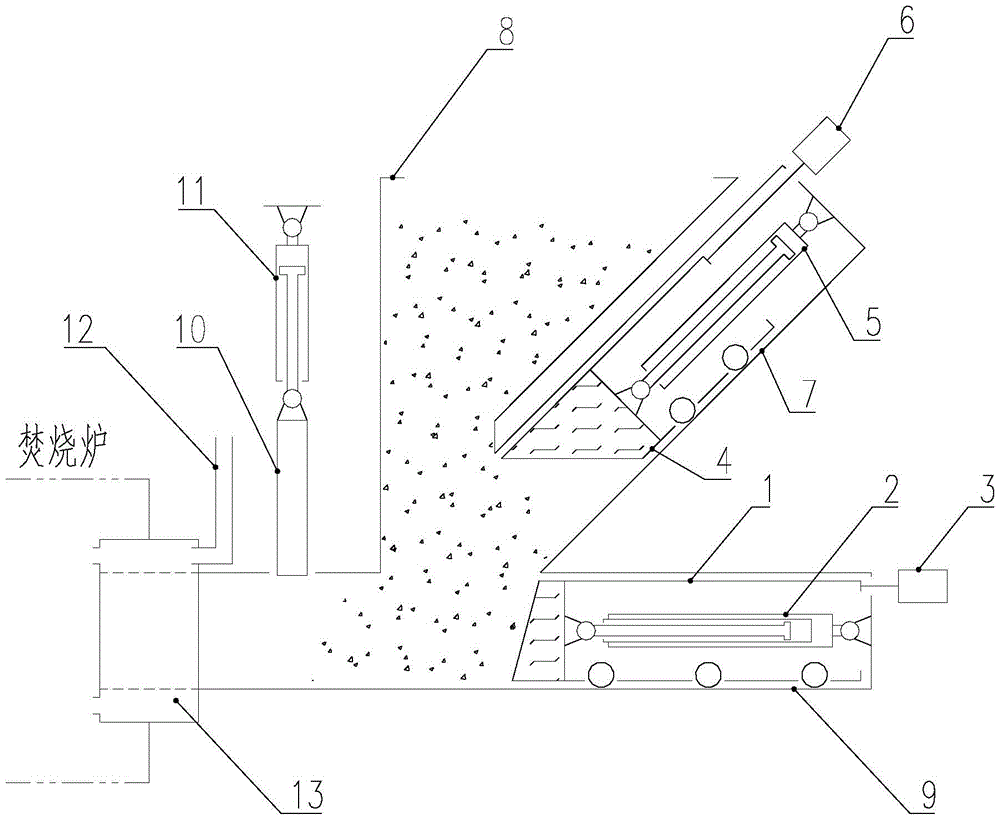

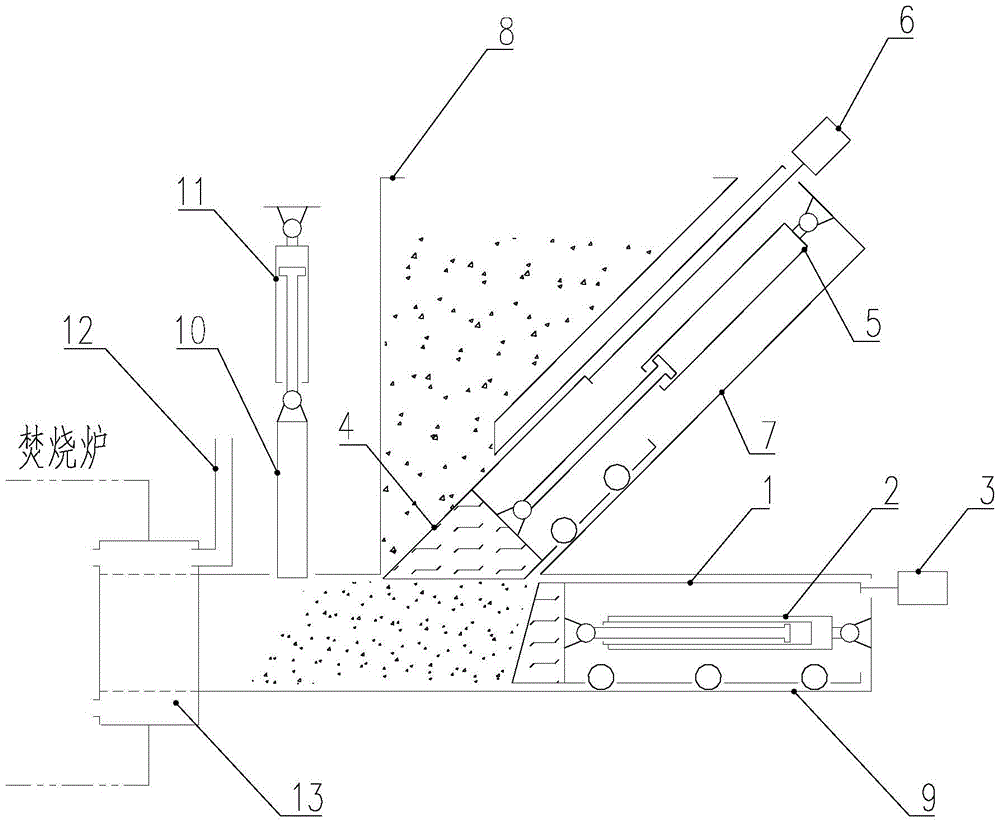

[0030] Such as figure 1 A hazardous waste incineration feeding device shown includes a substrate, a pushing unit, a pressing unit and an air-cooling unit. The substrate includes a pushing channel 9, a hopper 8 and a pressing channel 7, and the pushing channel 9 runs along the substrate. The bottom is set in the horizontal direction, the hopper 8 is set on the top of the substrate, and the pressing channel 7 is arranged obliquely between the pushing channel 9 and the hopper 8; the pushing unit is placed on the pushing channel 9 of the hopper 8, and along the pushing Road 9 moves, and the pressing unit is placed in the pressing channel 7 of the hopper 8, and moves along the pressing channel 7; The cooling air passage 12 on the cooling jacket 13, the air-cooling jacket 13 is ring-sleeved at the connection between the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com