A kind of graphene solar battery back plate film and preparation method thereof

A solar cell, graphene technology, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve problems such as unfavorable service life of battery panels, and achieve the effect of prolonging service life, and enhancing oxidation and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

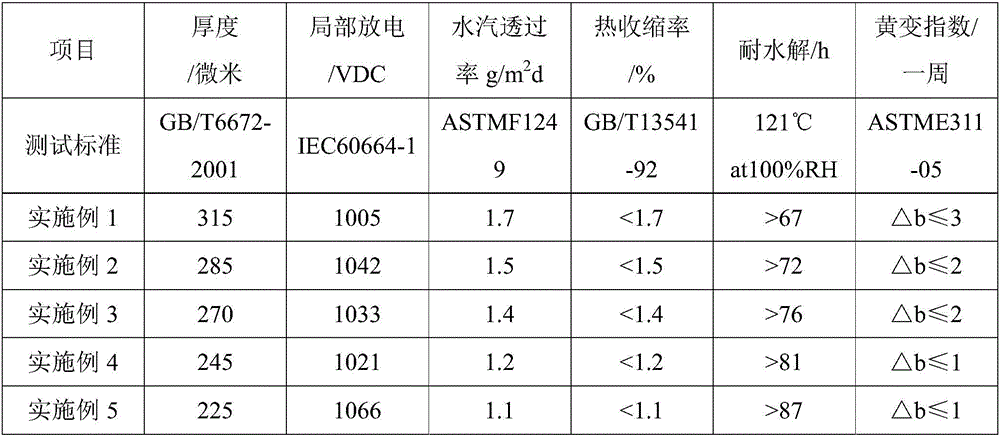

Examples

Embodiment 1

[0019] A graphene solar battery backplane film, comprising an outer film layer, a structural reinforcement layer and a barrier layer in sequence, wherein the outer film layer is made according to the following ratio of raw materials by weight: 30 parts of graphene, polyethylene terephthalate 20 parts of ester; the structural reinforcement layer is made according to the following ratio of raw materials by weight: 35 parts of cyclohexanedimethanol ester, 20 parts of polyethylene naphthalate; the barrier layer is made according to the ratio of the following raw materials by weight : Polyethylene 35 parts, polyethylene naphthalate 15 parts, graphene 20 parts.

[0020] A preparation method for a graphene solar battery back plate film, comprising the following steps:

[0021] (1) Heat and melt the graphene and polyethylene terephthalate components of the outer film layer at a temperature of 230°C; stir and mix evenly and quickly cool down and freeze at a cooling rate of 30°C / min; th...

Embodiment 2

[0026] A graphene solar cell backboard film, comprising an outer film layer, a structural reinforcement layer and a barrier layer in sequence, wherein the outer film layer is made according to the following ratio of raw materials by weight: 35 parts of graphene, polyethylene terephthalate 25 parts of ester; the structural reinforcement layer is made according to the following ratio of raw materials by weight: 40 parts of cyclohexanedimethanol ester, 25 parts of polyethylene naphthalate; the barrier layer is made according to the ratio of raw materials by weight : Polyethylene 40 parts, polyethylene naphthalate 20 parts, graphene 25 parts.

[0027] A preparation method for a graphene solar battery back plate film, comprising the following steps:

[0028] (1) Heat and melt the graphene and polyethylene terephthalate components of the outer film layer at a temperature of 235°C; stir and mix evenly and quickly cool down and freeze at a cooling rate of 35°C / min; the frozen mixture ...

Embodiment 3

[0033] A graphene solar cell backboard film, comprising an outer film layer, a structural reinforcement layer and a barrier layer in sequence, wherein the outer film layer is made according to the following ratio of raw materials by weight: 40 parts of graphene, polyethylene terephthalate 30 parts of ester; the structural reinforcement layer is made according to the following ratio of raw materials by weight: 45 parts of cyclohexanedimethanol ester, 30 parts of polyethylene naphthalate; the barrier layer is made according to the ratio of the following raw materials by weight : Polyethylene 45 parts, polyethylene naphthalate 25 parts, graphene 30 parts.

[0034] A preparation method for a graphene solar battery back plate film, comprising the following steps:

[0035] (1) Heating and melting the graphene and polyethylene terephthalate components of the outer film layer at a temperature of 240°C; stirring and mixing evenly and cooling down rapidly to freeze at a cooling rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com