Preparation method for polyvinylidene fluoride (PVDF)-based high voltage coefficient thin film

A high-voltage, thin-film technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, and can solve problems such as few reports on related properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

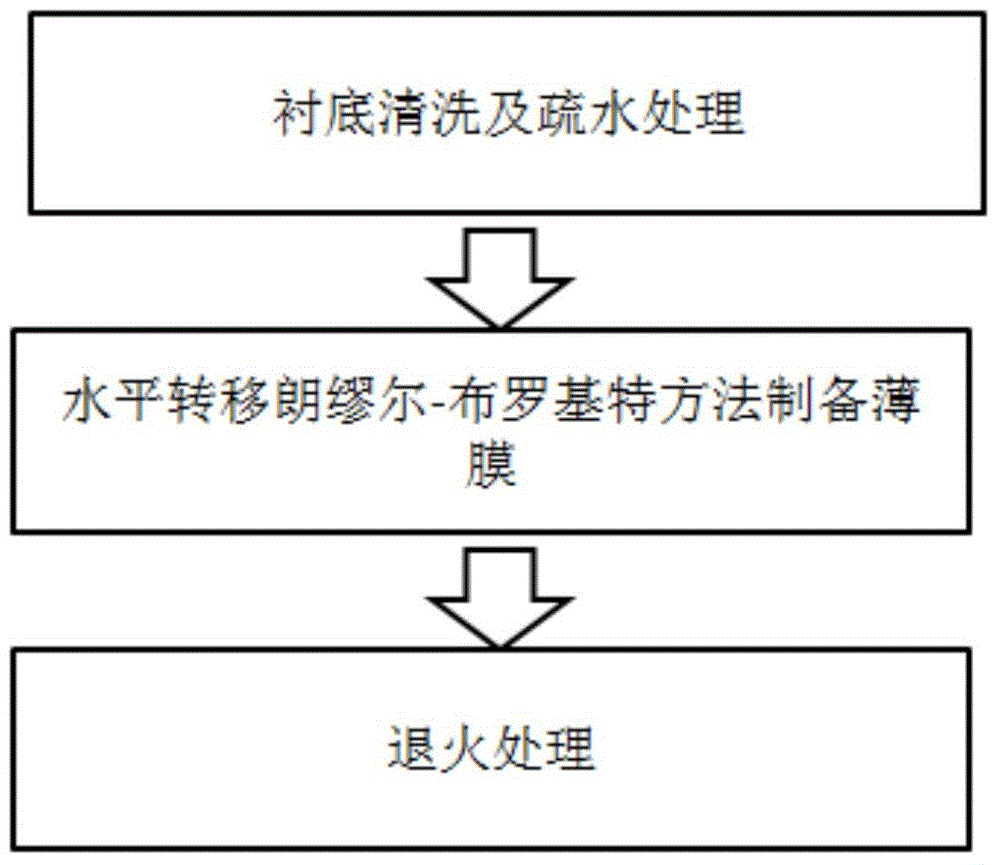

Method used

Image

Examples

Embodiment 1

[0020] The substrate material is cleaned to ensure the flatness of its surface, and the surface is treated with hydrophobicity; the substrate material can be quartz glass. Use iron stearate to wipe the surface repeatedly, wipe off the iron stearate residue attached to the surface with absorbent cotton, and then rinse the quartz glass substrate with deionized water.

[0021] Dissolve PVDF-based polymer P(VDF-TrFE) and PVDF-based polymer P(VDF-TrFE-CFE) organic ferroelectric polymer in dimethyl sulfoxide solution respectively, and the solution concentration is 0.01% by mass %.

[0022] Spread P(VDF-TrFE) and P(VDF-TrFE-CFE) organic ferroelectric polymer dimethyl sulfoxide solutions evenly into two Langmuir-Brockett equipments that have been injected with static ultrapure water. In the liquid tank, the resistance of ultrapure water is 18.2 megaohms. After the organic ferroelectric polymer is evenly distributed on the liquid surface, and the liquid surface is squeezed to form a f...

Embodiment 2

[0025] The substrate material is cleaned to ensure the flatness of its surface, and the surface is treated with hydrophobicity; the substrate material can be quartz glass. Use iron stearate to wipe the surface repeatedly, wipe off the iron stearate residue attached to the surface with absorbent cotton, and then rinse the quartz glass substrate with deionized water.

[0026] Dissolve PVDF-based polymer P(VDF-TrFE) and PVDF-based polymer P(VDF-TrFE-CFE) organic ferroelectric polymer in dimethyl sulfoxide solution respectively, and the solution concentration is 0.01% by mass %.

[0027] Spread P(VDF-TrFE) and P(VDF-TrFE-CFE) organic ferroelectric polymer dimethyl sulfoxide solutions evenly into two Langmuir-Brockett equipments that have been injected with static ultrapure water. In the liquid tank, the resistance of ultrapure water is 18.2 megaohms. After the organic ferroelectric polymer is evenly distributed on the liquid surface, and the liquid surface is squeezed to form a f...

Embodiment 3

[0030] The substrate material is cleaned to ensure the flatness of its surface, and the surface is treated with hydrophobicity; the substrate material can be quartz glass. Use iron stearate to wipe the surface repeatedly, wipe off the iron stearate residue attached to the surface with absorbent cotton, and then rinse the quartz glass substrate with deionized water.

[0031] Dissolve PVDF-based polymer P(VDF-TrFE) and PVDF-based polymer P(VDF-TrFE-CFE) organic ferroelectric polymer in dimethyl sulfoxide solution respectively, and the solution concentration is 0.01% by mass %.

[0032] Spread P(VDF-TrFE) and P(VDF-TrFE-CFE) organic ferroelectric polymer dimethyl sulfoxide solutions evenly into two Langmuir-Brockett equipments that have been injected with static ultrapure water. In the liquid tank, the resistance of ultrapure water is 18.2 megaohms. After the organic ferroelectric polymer is evenly distributed on the liquid surface, and the liquid surface is squeezed to form a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com