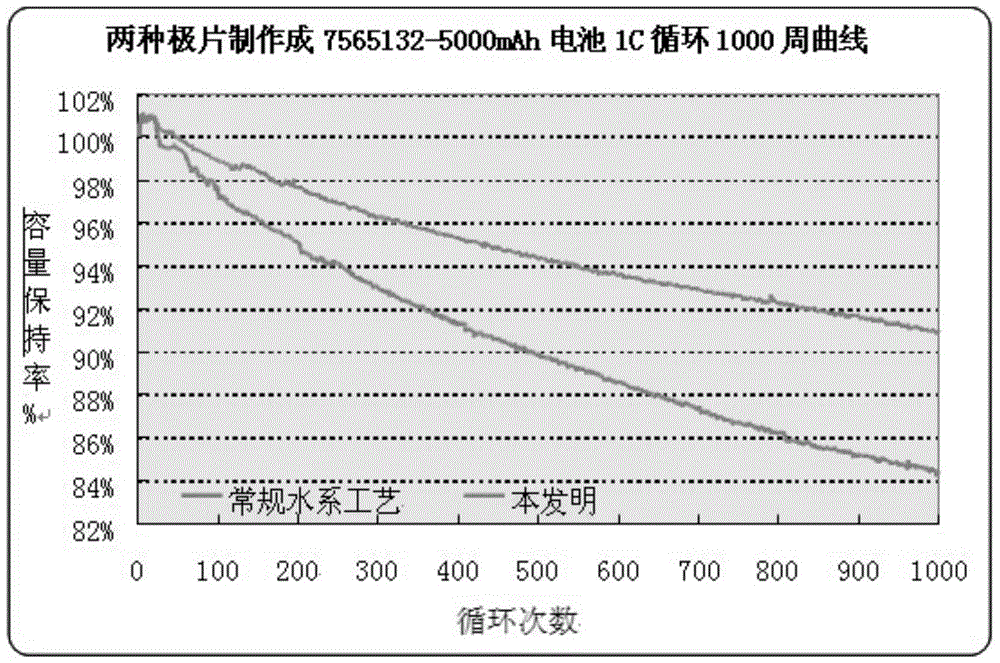

Preparation method of lithium iron phosphate battery positive plate using water-based adhesive and carbon-coated conductive aluminum foil current collector

A lithium iron phosphate battery and water-based binder technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problem of high cost of lithium iron phosphate power batteries, improve service life, improve energy density, reduce The effect of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the preparation method comprises the following steps;

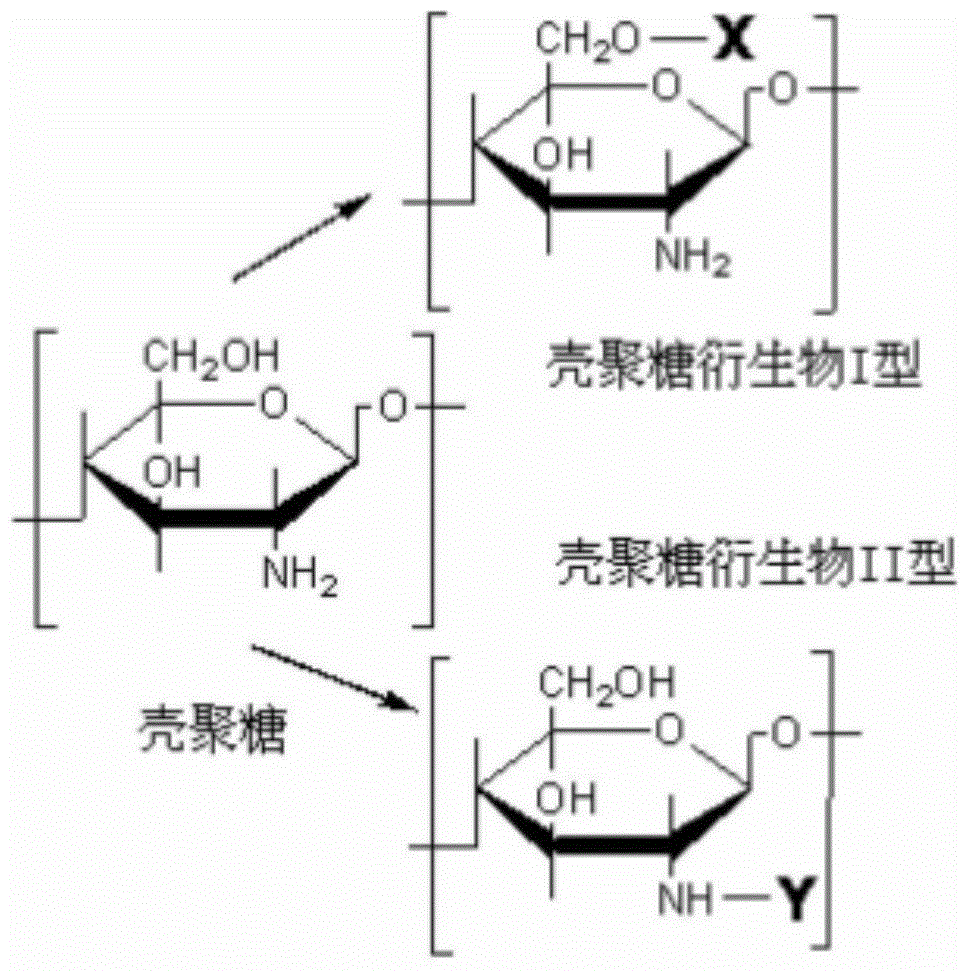

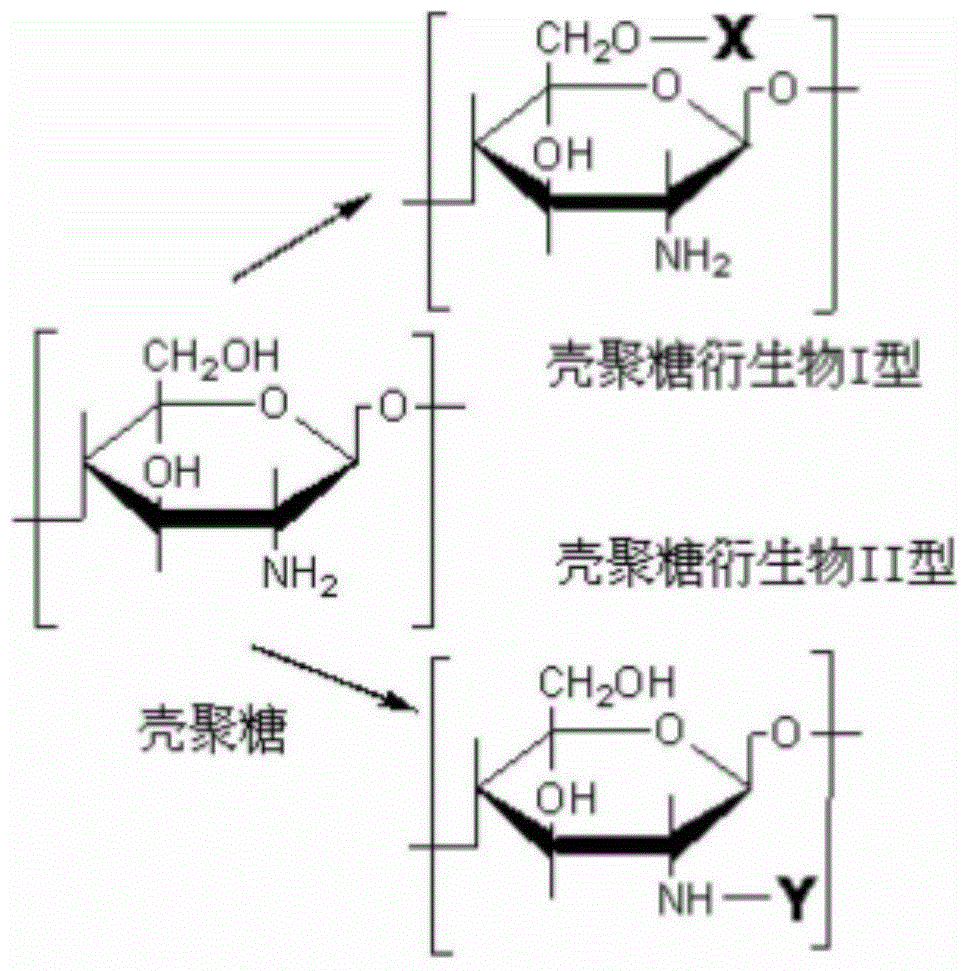

[0032] (1) Preparation of modified water-based binder; by mass parts, 35 parts of chitosan, 25 parts of polyethylene oxide, 20 parts of water-based binder, 11 parts of sodium carboxymethylcellulose and 10 parts of polyamino Formate (also known as PU glue) is fully mixed to prepare a water-based binder, in which polyethylene oxide, sodium carboxymethylcellulose and polyurethane can be obtained commercially. Preferably, the water-based binder can be the binder for lithium ion battery electrode materials disclosed in Publication No. 102760883A. Specifically, the water-based binder is chitosan and its derivatives shown in formula I, and the dispersion system is deionized water or 1% acetic acid-water mixed system;

[0033]

[0034] Wherein, X in derivative type I is selected from various hydrocarbon acyl groups, aromatic acyl groups, alkyl groups and aromatic groups; Y in derivative type II is selecte...

Embodiment 2

[0040] Embodiment 2: the preparation method comprises the following steps;

[0041] (1) Preparation of modified water-based binder; by mass parts, 40 parts of chitosan, 20 parts of polyethylene oxide, 20 parts of water-based binder, 10 parts of sodium carboxymethylcellulose and 10 parts of polyamino A water-based binder is obtained after the formate esters are thoroughly mixed.

[0042](2) Mix 4 parts of modified water-based binders with 80 parts of deionized water, and stir for 25 minutes under a vacuum condition of 1500 revolutions per minute and 15 revolutions per minute, and -0.9mpa; obtain product A;

[0043] (3) Add 3% conductive agent of A product quality to A product, stir until the conductive agent is fully wetted, and then stir for 200min under vacuum conditions of rotation 2700rpm / min and revolution 70rpm / min, and -0.9mpa; B product;

[0044] (4) Add 93 parts of lithium iron phosphate dry powder and 20 parts of deionized water to 1 part of product B, mix, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com