Colorful slowly-releasing compound fertilizer and preparation method thereof

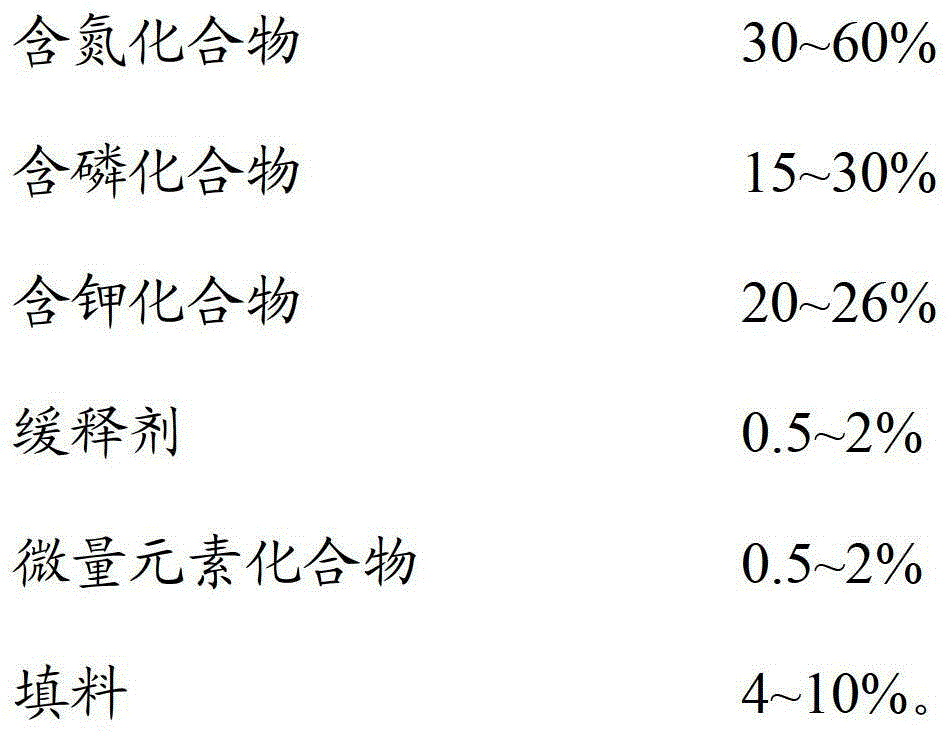

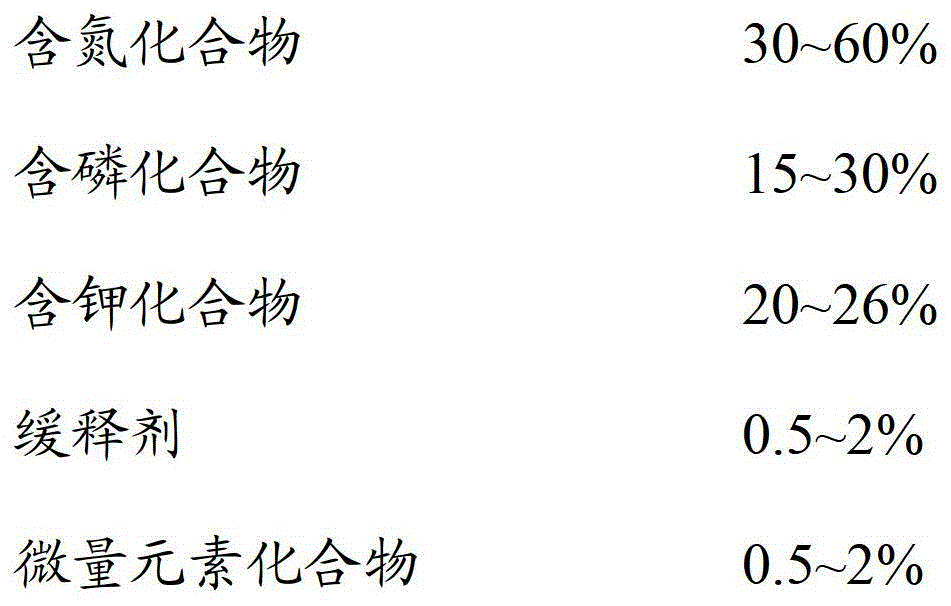

A slow-release compound fertilizer and color technology, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, potash fertilizer, etc., can solve the problems of single color, short fertilizer effect time, small particle size of compound fertilizer, etc., and achieve simple production process and long fertilizer effect time , the effect of large particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

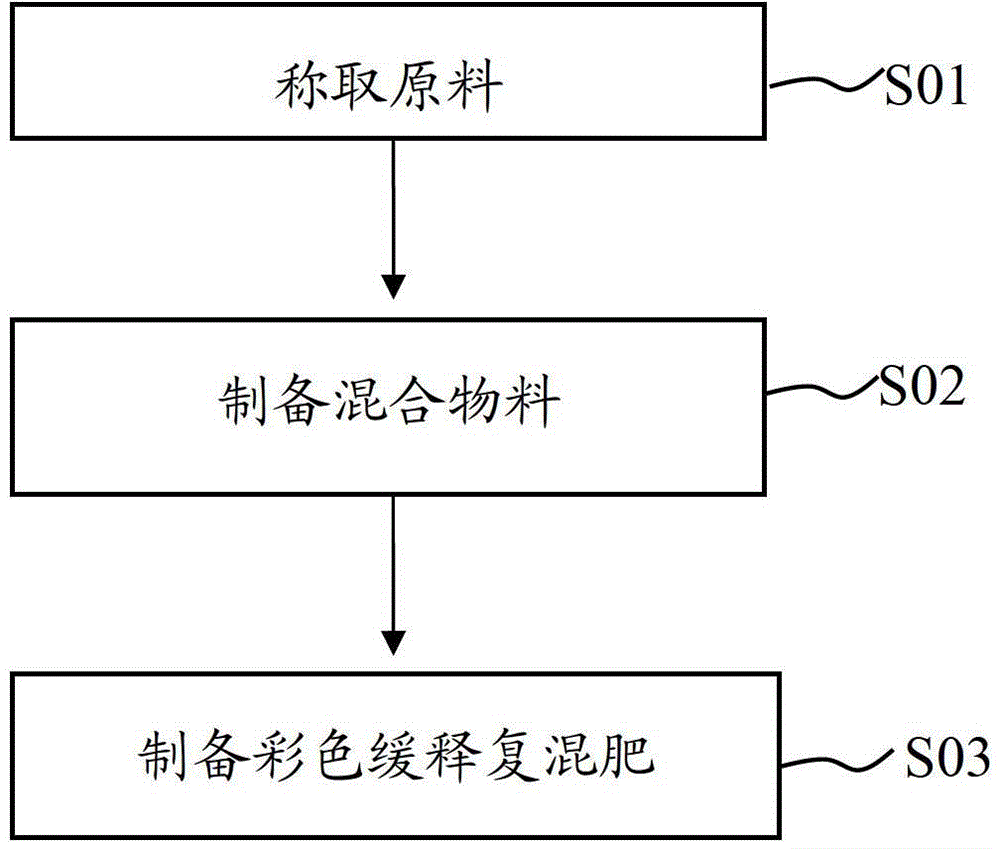

[0031] Correspondingly, the embodiments of the present invention further provide a method for preparing the above-mentioned colored slow-release compound fertilizer, comprising the following steps:

[0032]S01, weighing raw materials: weighing the above-mentioned nitrogen-containing compound, phosphorus-containing compound, potassium-containing compound, trace element compound and filler by electronic weighing according to the formula of the above-mentioned colored slow-release compound fertilizer;

[0033] S02, preparation of mixed material: the nitrogen-containing compound, phosphorus-containing compound, potassium-containing compound, trace element compound and filler are crushed and mixed with water to prepare a mixed material, and the weight percentage of the water in the mixed material is 1.0 ~2%;

[0034] S03, preparing a colored slow-release compound fertilizer: extruding the mixed material, drying, cooling, screening, and surface treatment to obtain a colored slow-rel...

Embodiment 1

[0050] The preparation method of the colored slow-release compound fertilizer of the embodiment of the present invention comprises the following steps:

[0051] S11: Use an electronic weighing scale to weigh urea (white), ammonium sulfate (white), monoammonium phosphate (white), potassium chloride (white or red), white dry powder, ingredients (trace elements + slow release agent + clay), The formula is: 22-9-10 (that is, 22% by weight of urea and ammonium sulfate, 9% by weight of monoammonium phosphate, and 10% by weight of potassium chloride); specifically, the weight ratio of raw materials The ratio is: 37 parts of urea, 15 parts of ammonium sulfate, 19 parts of monoammonium phosphate, 17 parts of potassium chloride, 5 parts of white dry powder, 2 parts of ferrous sulfate, 1 part of ingredients (including 0.2-05 parts of trace elements, 0.5-0.8 part slow-release agent, 0-0.5 part clay).

[0052] S12: Mix the components of the raw materials obtained in step S11 and crush the...

Embodiment 2

[0056] The preparation method of the colored slow-release compound fertilizer of the embodiment of the present invention comprises the following steps:

[0057] S21: Use an electronic weighing scale to weigh urea (white), ammonium sulfate (white), monoammonium phosphate (white), potassium chloride (white and red), white dry powder, ingredients (trace elements + slow release agent + clay), The formula is: 22-9-10 (that is, 22% by weight of urea and ammonium sulfate, 9% by weight of monoammonium phosphate, and 10% by weight of potassium chloride); specifically, the weight ratio of raw materials The ratio is: 32 parts of urea, 26 parts of ammonium sulfate, 19 parts of monoammonium phosphate, 9 parts of potassium chloride (white), 8 parts of potassium chloride (red), 3 parts of white dry powder, 2 parts of ferrous sulfate, and 1 part of ingredients (Contains 0.2-0.5 parts of trace elements, 0.5-0.8 parts of slow-release agent, 0-0.5 parts of clay).

[0058] S22: Mix the component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com