Cured composition, cured product thereof, hard primer and hard coating

A curable composition and compound technology, applied in coatings, antifouling/underwater coatings, biocide-containing paints, etc., can solve problems such as curling, large curing shrinkage, and large shrinkage, and achieve Excellent scratch resistance, low cure shrinkage, and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0159] Examples and comparative examples are shown below to explain the present invention in more detail.

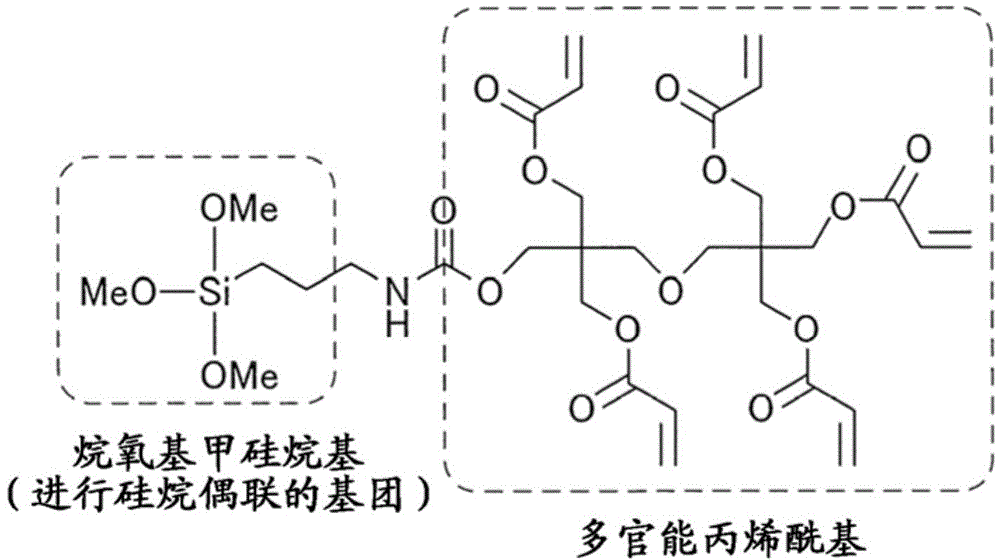

[0160](1) Synthesis of silane coupling agent (inorganic oxide particle modifier) having at least 2 acryloyl groups

Synthetic example 1

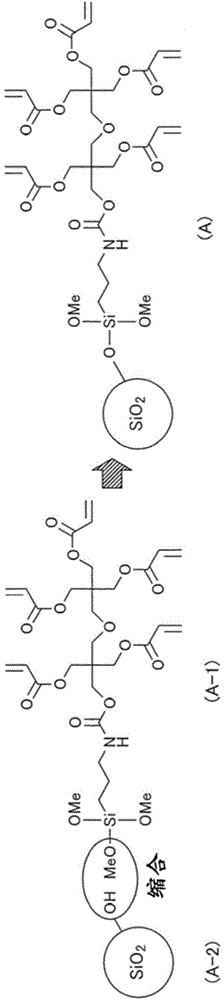

[0161] [Synthesis Example 1]: Synthesis of Inorganic Oxide Microparticle Modifier (D-1)

[0162] In a detachable flask, 129.2 g of toluene as a reaction solvent, a mixture of dipentaerythritol pentaacrylate and dipentaerythritol tetraacrylate (46.7% by mass of dipentaerythritol pentaacrylate, di A mixture of 23.1% by mass of pentaerythritol tetraacrylate, 27.9% by mass of dipentaerythritol hexaacrylate, and 2.3% by mass of other unknown substances; 100 g of DPPA mixture a) was heated while stirring so that the internal temperature of the detachable flask was 50° C., and prepared into a homogeneous solution.

[0163] Next, 29.2 g of 3-isocyanatopropyltriethoxysilane (trade name KBE-9007; manufactured by Shin-Etsu Chemical Co., Ltd.), which is an isocyanate compound having an alkoxysilyl group, and tetrachloride as a reaction catalyst were charged. 0.58 g of zirconium acetylacetonate (trade name ZC-700: manufactured by Matsumoto Fine Chemical Co., Ltd., 20% by mass non-volatile...

Synthetic example 2

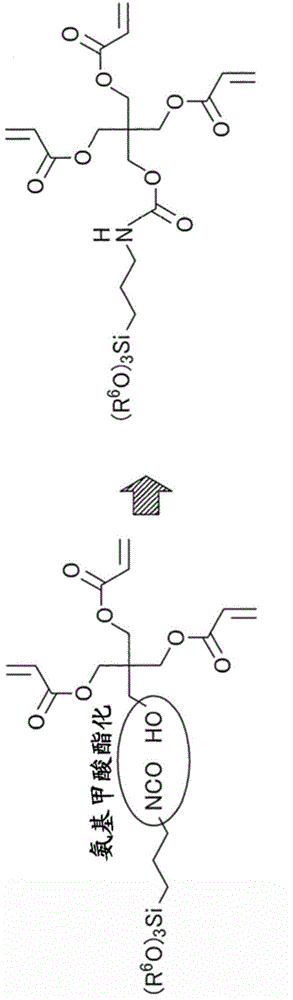

[0165] [Synthesis Example 2]: Synthesis of Inorganic Oxide Microparticle Modifier (D-2)

[0166] A mixture of dipentaerythritol pentaacrylate and dipentaerythritol tetraacrylate, which is a polyfunctional acrylate having a hydroxyl group, was replaced by a mixture of pentaerythritol triacrylate and pentaerythritol diacrylate, which is a polyfunctional acrylate having a hydroxyl group (pentaerythritol triacrylate 59.7% by mass, 9.6% by mass of pentaerythritol diacrylate, 21.8% by mass of pentaerythritol tetraacrylate, and 8.9% by mass of other unknown substances; PETA mixture), using dibutyltin dilaurate as a reaction catalyst, and In the same manner as in Synthesis Example 1 (see Table 1 for the amount of each compound used), 306 g of a toluene solution having a nonvolatile content of 48.4% by mass of the inorganic oxide fine particle modifying agent (D-2) was obtained.

[0167] [Table 1]

[0168] Table 1

[0169]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com