Adhesive composition, adhesive film and surface protection film

A composition and adhesive technology, applied in the direction of adhesives, adhesive types, conductive adhesives, etc., can solve the problems of difficult peeling, poor re-peelability, and difficult sticking, so as to prevent the phenomenon of adhesive residue and excellent Effect of Antistatic Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

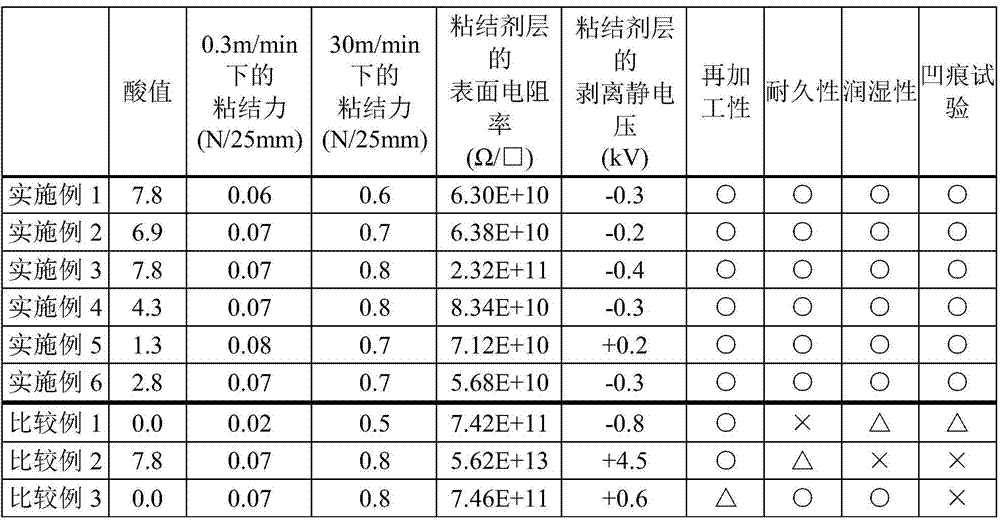

Examples

Embodiment 1

[0122] Nitrogen gas was introduced into a reaction apparatus equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen introduction pipe, thereby replacing the air in the reaction apparatus with nitrogen. Then, added 80 parts by weight of 2-ethylhexyl acrylate, 10 parts by weight of isotetradecyl acrylate, 8.5 parts by weight of 8-hydroxyoctyl acrylate, acrylic acid of 1.5 parts by weight in the reaction device, and At the same time, 60 parts by weight of solvent (ethyl acetate) was added. Then, after 2 hours, 0.1 parts by weight of azobisisobutyronitrile as a polymerization initiator was dripped and reacted at 65° C. for 6 hours to obtain the ( Meth)acrylic polymer solution 1. A part of the (meth)acrylic polymer was taken and used as a sample for acid value measurement described later.

Embodiment 2~6 and comparative example 1~3

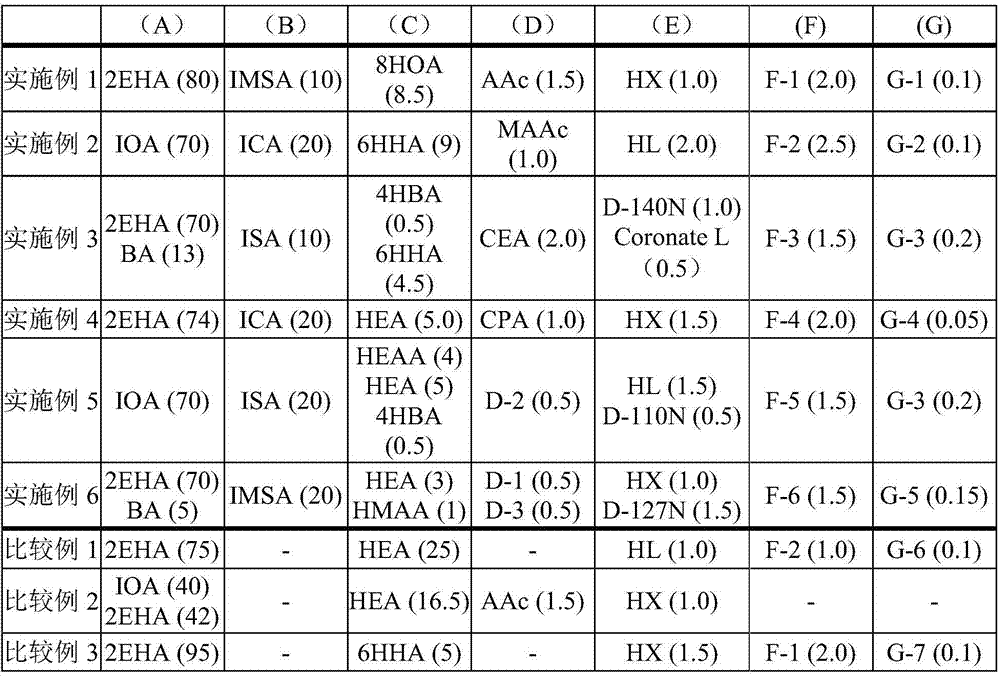

[0124] Except that the composition of each monomer was adjusted as described in (A) to (D) in Tables 1 and 2, it was carried out in the same manner as the above-mentioned (meth)acrylic polymer solution 1 used in Example 1. , (meth)acrylic polymer solutions used in Examples 2 to 6 and Comparative Examples 1 to 3 were obtained.

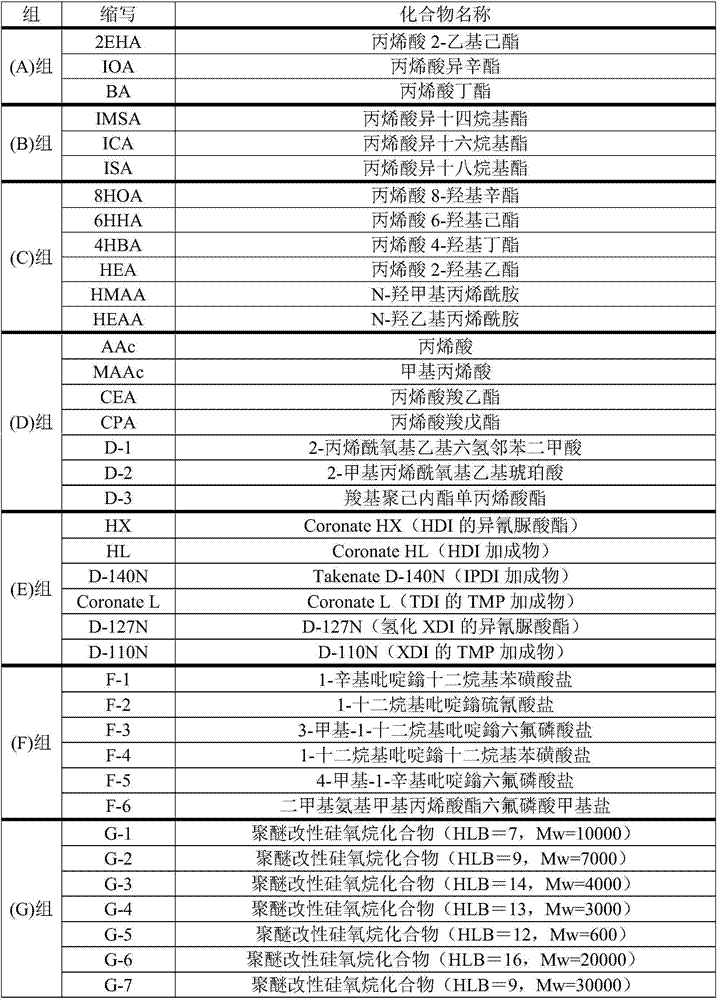

[0125] In addition, in Table 1 and Table 2, (A) is an alkyl (meth)acrylate having an alkyl group having 4 to 10 carbon atoms, and (B) is an alkyl group having 14 to 18 carbon atoms. Alkyl (meth)acrylate, (C) is a hydroxyl group-containing copolymerizable monomer, and (D) is a carboxyl group-containing copolymerizable monomer.

[0126] Table 1

[0127]

[0128]

[0129] [Example 1]

[0130] To the (meth)acrylic polymer solution 1 of Example 1 produced as described above, 2.0 parts by weight of 1-octylpyridinium dodecylbenzenesulfonate, 0.1 part by weight of After stirring the polyether-modified siloxane compound (weight-average molecular weight M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com