Ethicng liquid composition, and method for preparing array substrate for use in liquid crystal display device

A technology of liquid crystal display devices and array substrates, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of slow etching speed, low etching characteristics, and residue etching performance, so as to avoid residues and speed up the process , Improve the effect of etching speed

Active Publication Date: 2015-03-18

DONGWOO FINE CHEM CO LTD

View PDF6 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

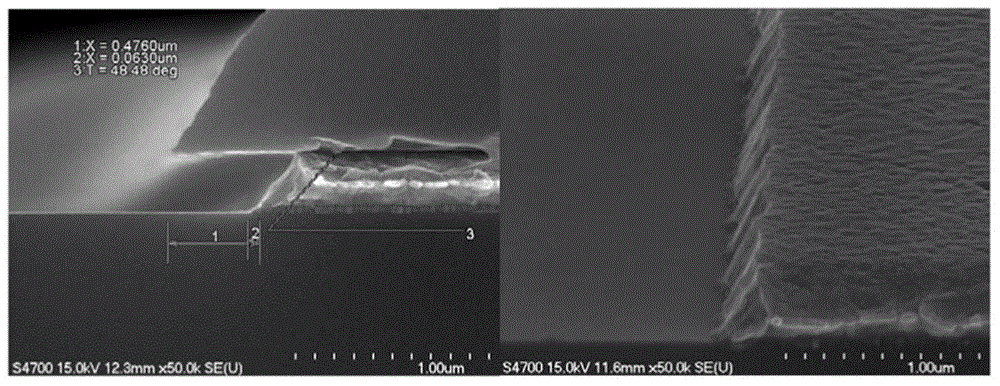

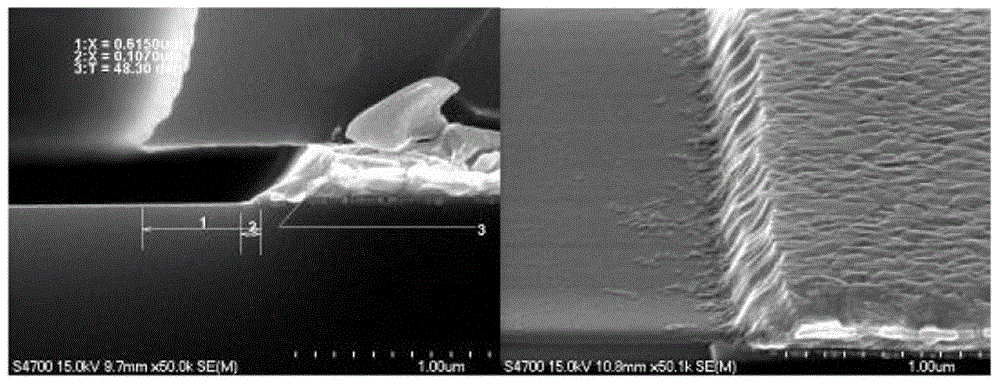

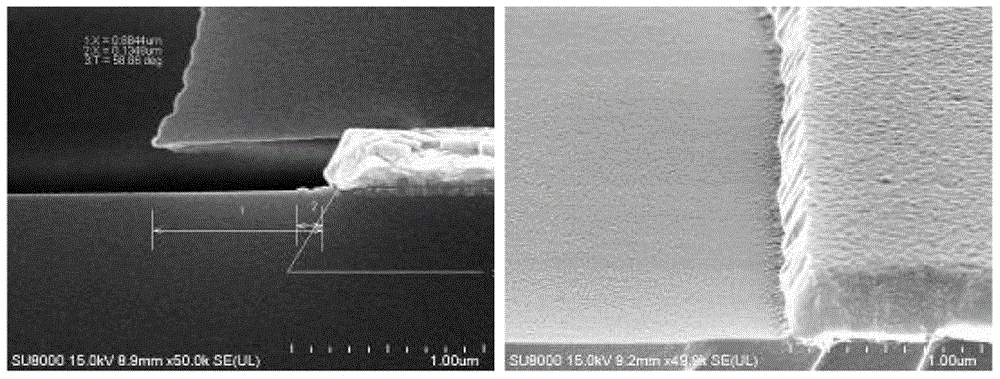

When the copper-molybdenum film is etched using the etching composition, a tapered profile with good linearity can be formed, but when the molybdenum-niobium (Mo-Nb) molybdenum-based metal film and the copper-based metal film are etched together , the etching speed becomes slower, and the molybdenum-niobium (Mo-Nb) molybdenum-based metal film cannot be etched or residues are generated, and the etching performance is extremely low.

Also, in Korean Laid-Open Patent Publication No. 10-2010-0035250, it is described that a composition including ammonium sulfate and cyclohexylamine must be included in hydrogen peroxide and the like, and when the composition is used to etch copper / molybdenum- Niobium (Mo-Nb) molybdenum-based metal film cannot achieve a sufficient etching rate for the copper film or molybdenum film, and the etching characteristics will also be severely reduced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 to Embodiment 3 and comparative example 1 to comparative example 10

[0056] The manufacture of embodiment 1 to embodiment 3 and comparative example 1 to comparative example 10 etchant composition

[0057] According to the compositions shown in Table 1 below, etching liquid compositions of Examples 1 to 3 and Comparative Examples 1 to 10 were produced.

[0058] [Table 1]

[0059] (unit: weight percentage)

[0060]

[0061]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an ethicng liquid composition, and a method for preparing an array substrate for use in a liquid crystal display device. The method comprises steps of forming grid wiring on a substrate, forming a grid insulation layer on the substrate containing the grid wiring, forming a semiconductor layer on the grid insulation layer, forming a source electrode and a drain electrode on the semiconductor layer, forming a pixel electrode connected with the drain electrode, and forming an electrode by etching films containing molybdenum metallic films or copper metallic films. A molybdenum alloy film is an alloy of niobium, tungsten or both with molybdenum. The ethicng liquid composition comprises, by weight percentage of total composition weight, 5.0%-25.0% of hydrogen peroxide, 0.01%-1.0% of fluorine compounds, 0.1%-5% of azole compounds, 0.1%-5.0% of water miscible compounds containing nitrogen atoms and carboxyl groups in a molecule, 0.1%-5.0% of phosphate compounds, 0.001%-5.0% of polyol surface active agents, and the balance of water. In addition, the ethicng liquid composition does not contain organic / inorganic acid or salt and cycloaliphatic amines

Description

technical field [0001] The present invention relates to a method for manufacturing an array substrate for a liquid crystal display device and an etchant composition for a multilayer film composed of a molybdenum alloy film of an alloy of one or more of niobium or tungsten and molybdenum and a copper-based metal film. Background technique [0002] Typical circuits for driving semiconductor devices and flat panel display devices are thin film transistors (TFT). In the manufacturing process of thin film transistors, a metal film is usually formed on the upper part of the substrate as a gate and data wiring material, and after forming a photoresist on a selective area of the metal film, the photoresist is used as a mask to etch the metal film. [0003] Generally, a copper-containing copper film or a copper alloy film having good conductivity and low electrical resistance, and a metal oxide film having excellent adhesion to the surface of these films are used as gate and data ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23F1/14H01L21/77

Inventor 李恩远李智娟权五柄崔容硕

Owner DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com