Prestressed concrete pile and production method thereof

A technology of concrete piles and prestressing, which is applied in the field of production of prestressed concrete piles and prestressed concrete piles, to achieve the effects of improving workability, delaying initial setting time, and improving interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

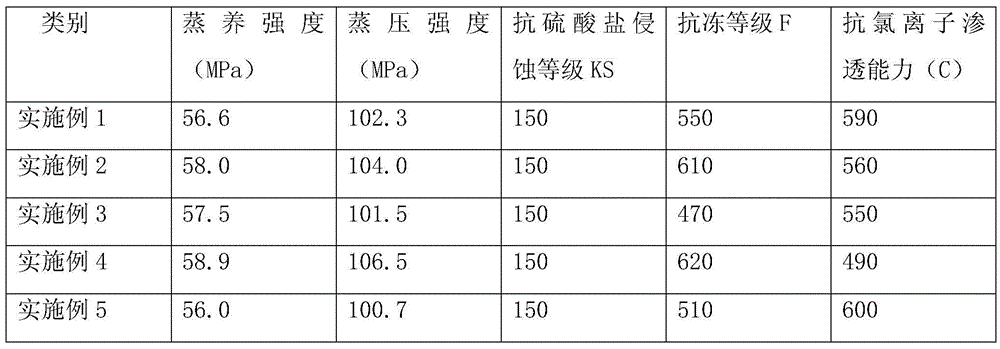

Examples

Embodiment 1

[0026] A prestressed concrete pile is cast by pumping high-strength concrete, and the pumping high-strength concrete includes the following components: cement, fine aggregate, coarse aggregate, water, mineral active material and admixture, and the admixture Including water reducer and retarder, the specific density of the concrete is 2450kg / m 3 , the amount of cement in the concrete per cubic meter is 450 kg, the fine aggregate is medium sand and its consumption is 530 kg, the fineness modulus of the medium sand is 2.3, and the SiO in the medium sand 2 content of 90%, the coarse aggregate is crushed stone, the amount of crushed stone is 1210㎏, the particle size of crushed stone is 8mm, the amount of water is 140㎏, the mineral active material is fly ash and its mixed The amount is 16% of the cement dosage, the water reducer is polycarboxylate high-performance water reducer and its dosage is 1.8% of the cement dosage, and the dosage of the retarder is 1.8% of the cement dosage. ...

Embodiment 2

[0035] A prestressed concrete pile is cast by pumping high-strength concrete, and the pumping high-strength concrete includes the following components: cement, fine aggregate, coarse aggregate, water, mineral active material and admixture, and the admixture Including water reducer and retarder, the concrete has a bulk density of 2470kg / m 3 , the amount of cement in the concrete per cubic meter is 460 kg, the fine aggregate is medium sand and its consumption is 540 kg, the fineness modulus of the medium sand is 2.4, and the SiO in the medium sand 2 content of 95%, the coarse aggregate is crushed stone, the amount of crushed stone is 1210kg, the particle size of crushed stone is 15mm, the amount of water is 145kg, the mineral active material is fly ash and its mixed The amount is 16% of the cement dosage, the water reducer is polycarboxylate high-performance water reducer and its dosage is 1.8% of the cement dosage, and the dosage of the retarder is 1.8% of the cement dosage. 0...

Embodiment 3

[0044] A prestressed concrete pile is cast by pumping high-strength concrete, and the pumping high-strength concrete includes the following components: cement, fine aggregate, coarse aggregate, water, mineral active material and admixture, and the admixture Including water reducer and retarder, the specific density of the concrete is 2480kg / m 3 , the consumption of the cement in the concrete per cubic meter is 470 kg, the fine aggregate is coarse sand and its consumption is 550 kg, the fineness modulus of the coarse sand is 2.8, and the SiO in the coarse sand 2 content of 92%, the coarse aggregate is pebbles, the amount of pebbles is 1220kg, the particle size of pebbles is 10mm, the amount of water is 150kg, the mineral active material is zeolite powder and its dosage is the above 17% of the amount of cement, the water reducer is polycarboxylate high-performance water reducer and its dosage is 1.9% of the amount of cement, and the amount of retarder is 0.15% of the amount of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com