Continuously-adjustable adjustment method and device for valve timing of engine

A technology of valve phasing and adjustment method, which is applied in the directions of engine components, machines/engines, valve devices, etc., can solve the problem of poor engine fuel economy harmful gas emission indicators, insignificant improvement effect of harmful gas emission indicators, and can not meet the requirements of simultaneous increase Or at the same time reduce problems such as improving intake and exhaust conditions, reducing useful power loss, and improving power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] An adjustment method for continuously adjustable engine valve timing, comprising:

[0022] (1) A gas distribution phase adjuster is connected in parallel in the hydraulic oil circuit between the cam cylinder and the valve cylinder of the variable valve mechanism of the hydraulic variable cam follower;

[0023] (2) The gas distribution phase regulator includes the gas distribution phase regulator oil cylinder, the gas distribution phase regulator piston, the piston return device and the limit device, and the return force generated by the piston return device keeps the piston at zero position ( The position where the volume of the cylinder of the valve phase regulator is zero) moves in the direction, the stroke of the piston of the valve phase regulator from zero position to the limit device is controlled by the limit device, and the oil flowing into the cylinder of the valve phase regulator is controlled The liquid volume, and then control the moment when the oil flows i...

Embodiment 2

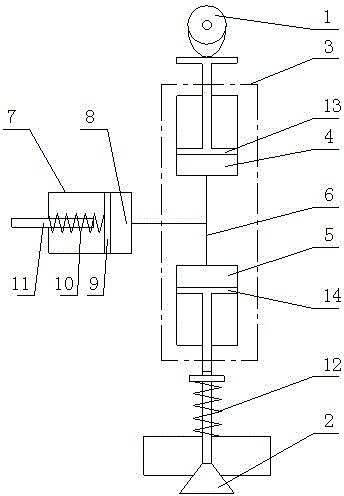

[0028] An adjustment device for continuously adjustable engine valve timing, including a cam 1 and a valve 2, a hydraulic system 3 is provided between the cam 1 and the valve 2, wherein: a hydraulic oil circuit 6 between the cam cylinder 4 and the valve cylinder 5 A gas distribution phase regulator 7 is connected in parallel in the middle, and the gas distribution phase regulator 7 includes a gas distribution phase regulator cylinder 8, a gas distribution phase regulator piston 9, a gas distribution phase regulator spring 10, and a gas distribution phase regulator limit rod 11 , The gas distribution regulator piston 9 is located in the gas distribution regulator cylinder 8, and the gas distribution regulator piston 9 rear end is provided with a gas distribution regulator spring 10 and a gas distribution regulator limit rod 11.

[0029] The hydraulic system overcomes the pretightening force of the valve phase regulator spring 10 and the force of the valve phase regulator spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com