Photosensitive Resin Composition Used For Color Filter And Application Thereof

A technology for color filters and photosensitive resins, applied in the field of color filters, can solve the problems of poor development resistance, less relative usage, and poor stability of the viscosity of photosensitive resin compositions over time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example A-1-1

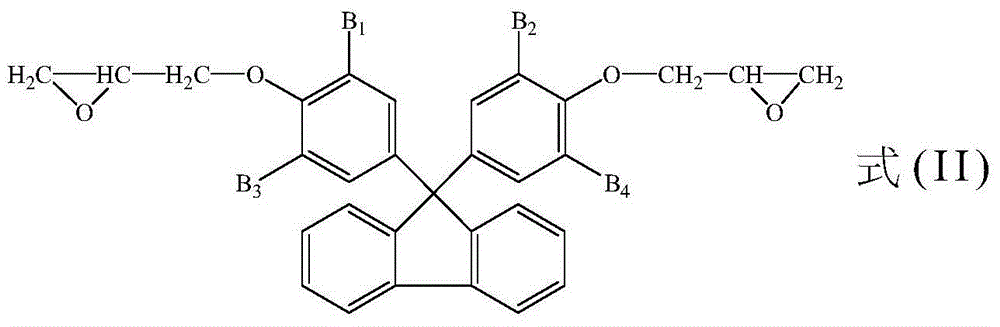

[0143] With 100 parts by weight of fluorene epoxy compound (manufactured by Nippon Steel Chemical, the model is ESF-300; epoxy equivalent is 231), 30 parts by weight of acrylic acid, 0.3 parts by weight of benzyltriethylammonium chloride, 0.1 parts by weight of Parts of 2,6-di-tert-butyl-p-cresol and 130 parts by weight of propylene glycol methyl ether acetate are continuously added to a 500-milliliter four-necked flask, and the feed rate is controlled at 25 parts by weight / minute, and the temperature is maintained In the range of 100°C to 110°C. After reacting for 15 hours, a light yellow transparent mixed liquid can be obtained, and its solid content concentration is 50% by weight.

[0144] Then, 100 parts by weight of the above mixed solution was added to 25 parts by weight of ethylene glycol ether acetate, while adding 6 parts by weight of tetrahydrophthalic anhydride and 13 parts by weight of benzophenone tetracarboxylic dianhydride , and heated to 110°C to 115°C. After...

Synthetic example A-1-2

[0146] With 100 parts by weight of fluorene epoxy compound (manufactured by Nippon Steel Chemical, the model is ESF-300; epoxy equivalent is 231), 30 parts by weight of acrylic acid, 0.3 parts by weight of benzyltriethylammonium chloride, 0.1 parts by weight of Parts of 2,6-di-tert-butyl-p-cresol and propylene glycol methyl ether acetate of 130 parts by weight are continuously added to the four-necked flask of 500 milliliters, and the feeding speed is controlled at 25 parts by weight / minute, and the temperature is maintained at Within the range of 100° C. to 110° C., after 15 hours of reaction, a light yellow transparent mixed liquid with a solid content concentration of 50 weight percent can be obtained.

[0147] Next, 100 parts by weight of the above mixed solution was dissolved in 25 parts by weight of ethylene glycol ether acetate, and 13 parts by weight of benzophenone tetracarboxylic dianhydride was added at the same time, and heated to 90°C to 95°C. After reacting for 2...

Synthetic example A-1-3

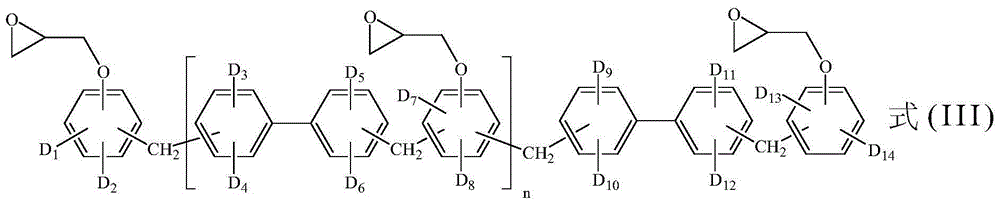

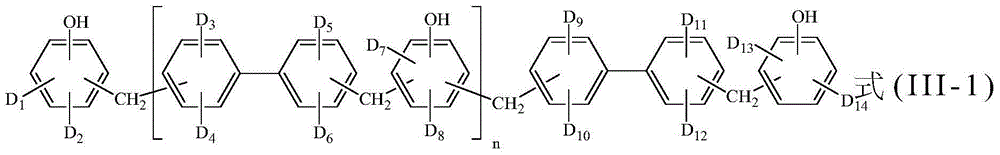

[0149]With 400 parts by weight of epoxy compound (manufactured by Nippon Kayaku Co., Ltd., model is NC-3000; epoxy equivalent is 288), 102 parts by weight of acrylic acid, 0.3 parts by weight of methoxyphenol (methoxyphenol), 5 parts by weight Parts of triphenylphosphine and 264 parts by weight of propylene glycol methyl ether acetate were added into the reaction flask, and the temperature was maintained at 95°C. After reacting for 9 hours, an intermediate product with an acid value of 2.2 mgKOH / g can be obtained. Then, add 151 parts by weight of tetrahydrophthalic anhydride (tetrahydrophthalic anhydride), and react at 95° C. for 4 hours to obtain alkali-soluble resin (A-1-3), whose acid value is 102 mgKOH / g, And the weight average molecular weight was 3200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com