Positive type photoresist stripping agent

A technology of photoresist stripping agent and photoresist, which is applied in the direction of photosensitive material processing, etc., can solve the problems of high evaporation rate, limit the service life of photoresist stripper bath, and cannot remove photoresist, so as to achieve low evaporation rate and increase operation Safety, easy recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

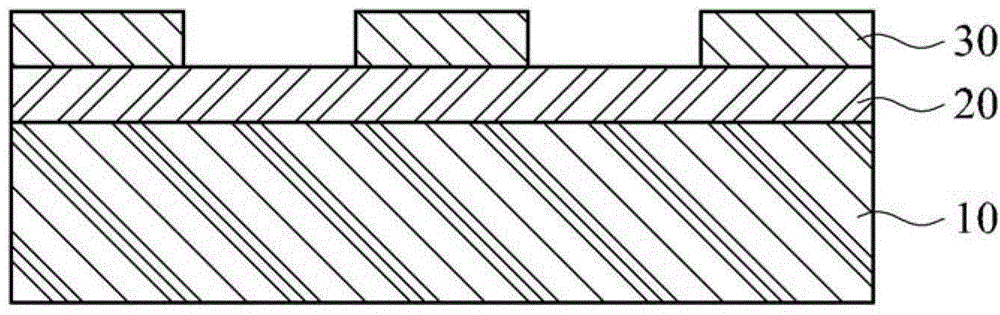

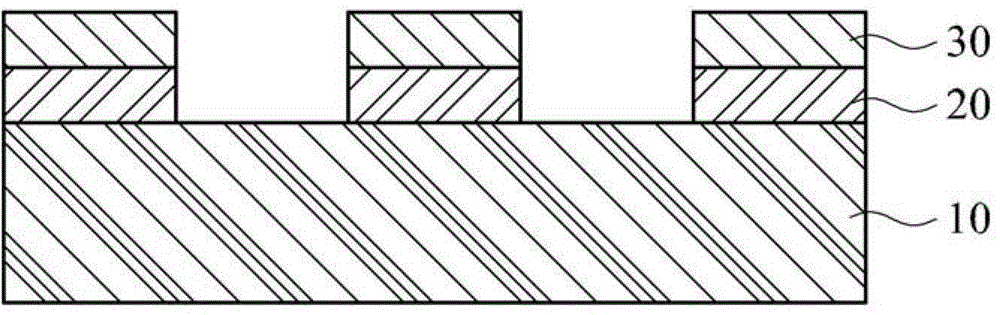

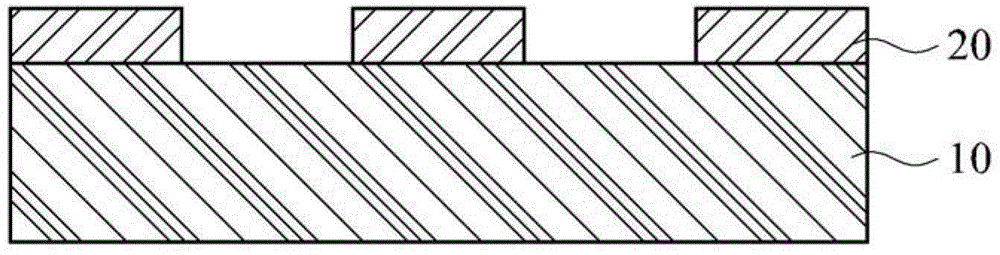

Image

Examples

Embodiment

[0085] Material:

[0086] Diethylenetriamine (DETA), monoethanolamine (MEA), N-methylpyrrolidone (NMP), N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAc) and N , N-diethylacetamide (DEAc) was purchased from Alfa

[0087] N,N-Dimethylpropanamide (DMPA) was purchased from Tokyo Chemical Industry Co., Ltd. .

[0088] Fluorosurfactant (FS) is a nonionic fluorosurfactant obtained from DuPont, which is a polyoxyethylene compound substituted by fluorinated fatty alcohol, and its trade name is FS-3100.

[0089] The positive photoresist is model Echem TM120SL, purchased from eChem Solutions Corp.

[0090] The water is deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com