Current collector structure

A technology of current collection and layer structure, which is applied to structural parts, circuits, electrical components, etc., can solve the problems of poor adhesion, difficulty in implementation, and difficult control of uniformity, and achieve the effect of increasing adhesion strength, low contact resistance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be described in more detail below with reference to the drawings and reference numbers, so that those skilled in the art can implement them with reference to the description.

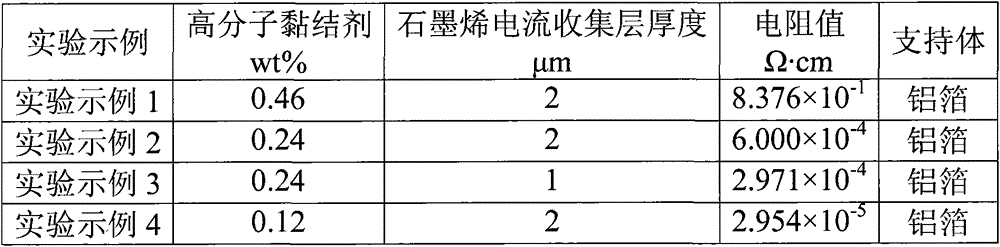

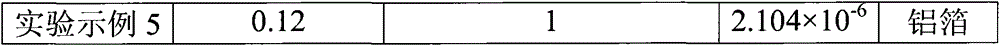

[0015] refer to figure 1 , is a schematic cross-sectional view of the current collection layer structure of the present invention. Such as figure 1 As shown, the current collecting layer structure 1 of the present invention includes a metal foil base layer 10 and a graphene conductive layer 20, and the metal foil base layer is selected from any one of aluminum foil, copper foil, titanium foil, and nickel foil. The graphene conductive layer 20 is arranged on at least one surface of the metal foil base layer 10, with a thickness of 0.1 μm to 5 μm, and a resistance value of less than 1Ω·cm; the graphene conductive layer 20 includes a plurality of graphene sheets, and a polymer bonding agent, the polymer adhesive is used to adhere the graphene sheet to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com