Vacuum low-temperature fried lotus nelumbo nucifera gaertn crisp chips and preparation method thereof

A technology of vacuum low-temperature frying and lotus root strips, which is applied in the field of food processing to achieve the effects of ensuring activity, improving palatability and digestibility, and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

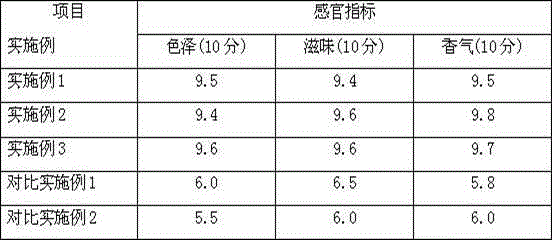

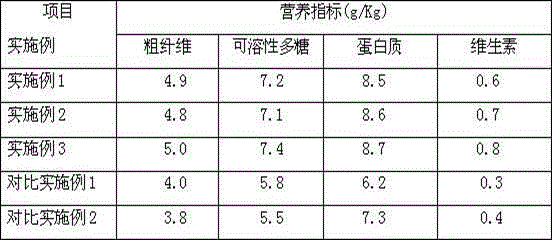

Examples

Embodiment 1

[0023] (1) Preparation of lotus pulp: picking lotus flowers that are fully bloomed, fresh and tender, rinsed with clean water, and mixed in (mass percentage concentration ratio): 2.6% NaCl, 0.5% citric acid, 0.4% CaCl, 0.10% ascorbic acid Treat in the color-protecting aqueous solution, soak for 40 minutes, drain the water on the surface, refine the pulp by colloid mill, and inactivate the enzyme and prevent browning by heating with a plate heat exchanger. The temperature for inactivating the enzyme is 86 ℃, the time is 6min;

[0024] (2) Preparation of lotus root pulp: take fresh lotus root, wash it with water, remove the head and tail of the lotus root, cut it into pieces, put it in a salt solution with a concentration of 15:1 (g / L), and use ultrasonic waves at a frequency of 60KHz Sonicate for 25 minutes, drain, and use a colloid mill to refine the pulp to obtain the lotus root pulp for later use;

[0025] (3) Preparation of mixed pulp: Take lotus pulp and lotus root pulp ...

Embodiment 2

[0031] (1) Preparation of lotus pulp: picking lotus flowers that are fully bloomed, fresh and tender, rinsed with clean water, and mixed in (mass percentage concentration ratio): 2.6% NaCl, 0.5% citric acid, 0.4% CaCl, 0.10% ascorbic acid Treatment in the color-protecting aqueous solution, soaking time is 60 minutes, drain the water on the surface, and use the colloid mill to refine the beating, and heat the plate heat exchanger to kill the enzyme and prevent browning. The temperature for killing the enzyme is 90 ℃, the time is 9min;

[0032] (2) Preparation of lotus root pulp: take fresh lotus root, wash it with water, remove the head and tail of the lotus root, cut it into pieces, put it in a salt solution with a concentration of 50:1 (g / L), at a frequency of 80 KHz Sonicate under ultrasonic wave for 45 minutes, drain, and use a colloid mill to refine the pulp to obtain the lotus root pulp for later use;

[0033] (3) Preparation of mixed pulp: Take lotus pulp and lotus roo...

Embodiment 3

[0039](1) Preparation of lotus pulp: picking lotus flowers that are fully bloomed, fresh and tender, rinsed with clean water, and mixed in (mass percentage concentration ratio): 2.6% NaCl, 0.5% citric acid, 0.4% CaCl, 0.10% ascorbic acid Treat in the color-protecting aqueous solution, soak for 50 minutes, drain the water on the surface, refine the pulp by colloid mill, and inactivate the enzyme and prevent browning by heating with a plate heat exchanger. The temperature for inactivating the enzyme is 88 ℃, the time is 8min;

[0040] (2) Preparation of lotus root pulp: take fresh lotus root, wash it with water, remove the head and tail of the lotus root, cut it into pieces, put it in a salt solution with a concentration of 35:1 (g / L), at a frequency of 70 KHz Sonicate under ultrasonic wave for 30 minutes, drain, and use colloid mill to refine pulp to obtain lotus root pulp for later use;

[0041] (3) Preparation of mixed pulp: take lotus pulp and lotus root pulp according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com