Low-wear fluidized bed catalyst for preparing aromatics from methanol and preparation method of low-wear fluidized bed catalyst for preparing aromatics from methanol

A fluidized bed catalyst, catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low catalyst wear, low yield of propylene and aromatic hydrocarbons, poor catalyst stability, etc. Selectivity, increased solids content, improved effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

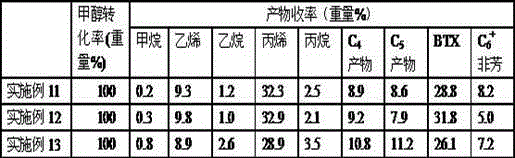

Examples

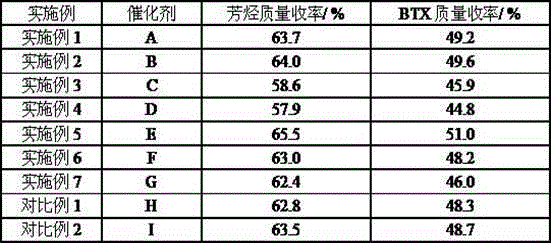

Embodiment 1

[0037] 1) Weigh 160g of water, 12g of concentrated phosphoric acid, mix well, add 180g of aluminum sol, 120g of kaolin and 100g of ZSM-5 molecular sieve, and use a colloid mill to mix vigorously for 20 minutes to obtain the required slurry for spray drying.

[0038] 2) Spray-dry the obtained slurry to make microspheres of 20-200 μm, and bake them at 600°C for 4 hours to form them.

[0039] 3) Take 150g of formed microspheres, use zinc nitrate solution as the impregnating solution, and use the impregnation method to load zinc element, and finally dry at 120°C for 10h, and burn at 600°C for 4h to obtain methanol-to-aromatics fluidized bed catalyst A. The zinc in the obtained catalyst The element content is 3.0%.

Embodiment 2

[0041] The difference from Example 1 is that during the slurry preparation process, the amount of concentrated phosphoric acid added is 3.0 g, and the rest of the steps are the same as in Example 1 to obtain catalyst B.

[0042]

Embodiment 3

[0044] 1) Weigh 210g of water, 5g of ammonium phosphate, and 2g of phosphoric acid to dissolve evenly, add 160g of aluminum sol, 100g of kaolin, and 110g of ZSM-5 molecular sieve, and use a colloid mill to mix vigorously for 30 minutes to obtain the slurry required for spray drying.

[0045] 2) Spray-dry the obtained slurry to make microspheres of 20-200 μm, and bake them at 650°C for 2 hours to form them.

[0046] 3) Take 150g of molded microspheres and load 1.5% of the metal element gallium by impregnation method. Dry at 100°C for 16 hours, and burn at 580°C for 8 hours to obtain methanol-to-aromatics fluidized-bed catalyst C.

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com