A kind of high-hardness transparent glass-ceramics and its preparation method

A glass-ceramic, high-hardness technology, applied in the field of new materials, can solve the problems of poor visible light transmittance, low glass transparency, and limited application, and achieve high visible transmittance, lower nucleation barrier, and lower activation energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

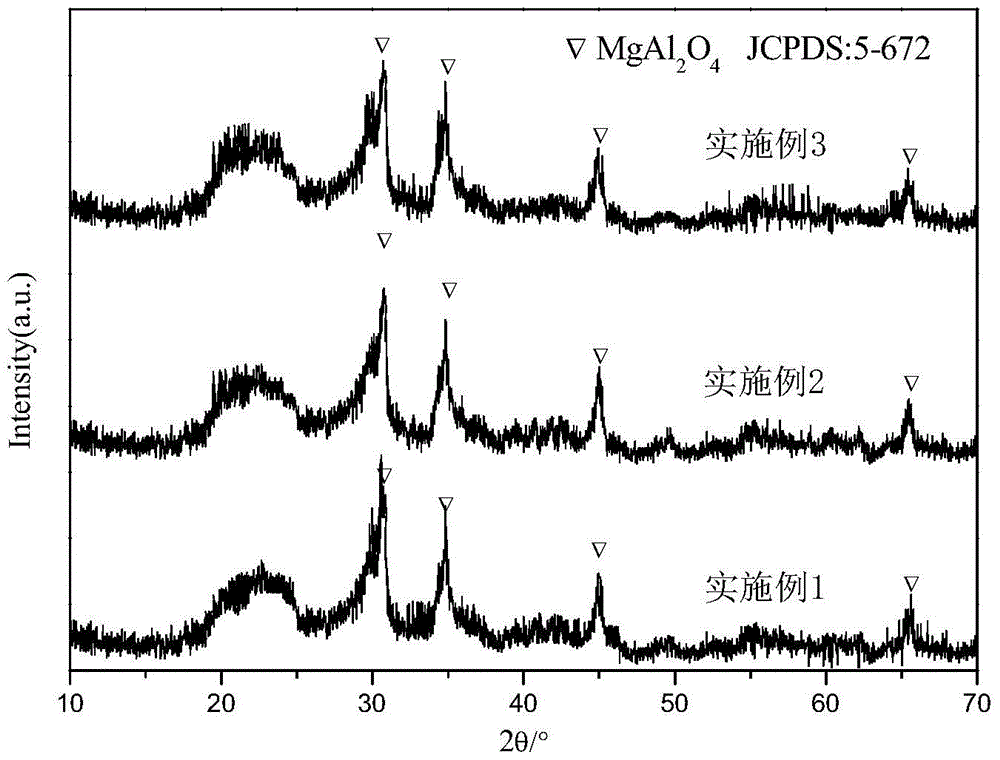

Embodiment 1

[0019] A high-hardness transparent glass-ceramic, its composition weight percentage is: silicon dioxide 60%, aluminum oxide 18%, magnesium oxide 8%, diyttrium oxide 0.2%, zirconium dioxide 6%, zinc dioxide 5% %, antimony trioxide 0.55%, diboron trioxide 2%, phosphorus pentoxide 0.25%.

[0020] The preparation method of the above-mentioned high-hardness transparent glass-ceramic comprises the following steps:

[0021] (1) According to the following formula by weight percentage, the raw materials are weighed and mixed evenly, 60% of silicon dioxide, 18% of aluminum oxide, 8% of magnesium oxide, 0.2% of diyttrium oxide, 6% of zirconium dioxide, and 5% of zinc dioxide , antimony trioxide 0.55%, diboron trioxide 2%, phosphorus pentoxide 0.25%.

[0022] (2) Grind the components of the above-mentioned glass-ceramics evenly to make a mixture, put it in a crucible and heat it up to 1650-1700°C for melting, keep it warm for 2-4 hours, and fully melt and clarify.

[0023] (3) Pour the ...

Embodiment 2

[0027] A high-hardness transparent glass-ceramic, its composition weight percentage is: 55% of silicon dioxide, 20% of aluminum oxide, 10% of magnesium oxide, 0.15% of diyttrium oxide, 6.35% of zirconium dioxide, 6% of zinc dioxide %, antimony trioxide 0.5%, diboron trioxide 1.8%, phosphorus pentoxide 0.2%.

[0028] The preparation method of the above-mentioned high-hardness transparent glass-ceramic comprises the following steps:

[0029] (1) According to the following formula by weight percentage, the raw materials are weighed and mixed evenly, 55% of silicon dioxide, 20% of aluminum oxide, 10% of magnesium oxide, 0.15% of diyttrium oxide, 6.35% of zirconium dioxide, and 6% of zinc dioxide , antimony trioxide 0.5%, boron trioxide 1.8%, phosphorus pentoxide 0.2%.

[0030] (2) Grind the components of the above-mentioned glass-ceramics evenly to make a mixture, put it in a crucible and heat it up to 1650-1700°C for melting, keep it warm for 2-4 hours, and fully melt and clarif...

Embodiment 3

[0035] A high-hardness transparent glass-ceramic, its composition weight percentage is: silicon dioxide 58%, aluminum oxide 20%, magnesium oxide 8%, diyttrium oxide 0.17%, zirconium dioxide 6.15%, zinc dioxide 5% %, antimony trioxide 0.5%, diboron trioxide 2%, phosphorus pentoxide 0.18%.

[0036] The preparation method of the above-mentioned high-hardness transparent glass-ceramic comprises the following steps:

[0037] (1) According to the following formula by weight percentage, the raw materials are weighed and mixed evenly, 58% of silicon dioxide, 20% of aluminum oxide, 8% of magnesium oxide, 0.17% of diyttrium oxide, 6.15% of zirconium dioxide, and 5% of zinc dioxide , antimony trioxide 0.5%, boron trioxide 2%, phosphorus pentoxide 0.18%.

[0038] (2) Grind the components of the above-mentioned glass-ceramics evenly to make a mixture, put it in a crucible and heat it up to 1650-1700°C for melting, keep it warm for 2-4 hours, and fully melt and clarify.

[0039] (3) Pour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com