High-wave impedance concrete as well as preparation method and application thereof

A wave impedance and concrete technology, which is applied in the field of preparation, high wave impedance concrete, and hole bottom accumulation-energy dissipation base, can solve the problems of difficult forming and processing of steel materials, difficult large-scale application, time-consuming and labor-intensive, etc., to improve the utilization rate of blasting energy and the flatness of the bottom of the hole, increase the density of stones, and have good economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

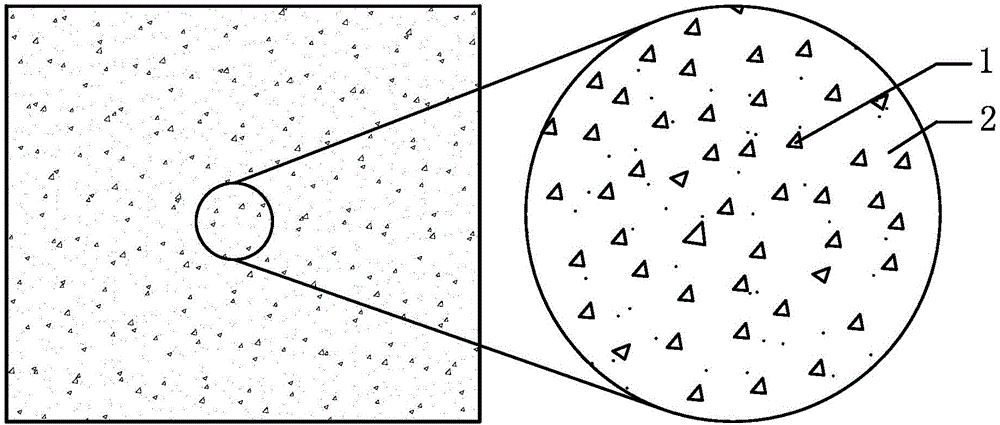

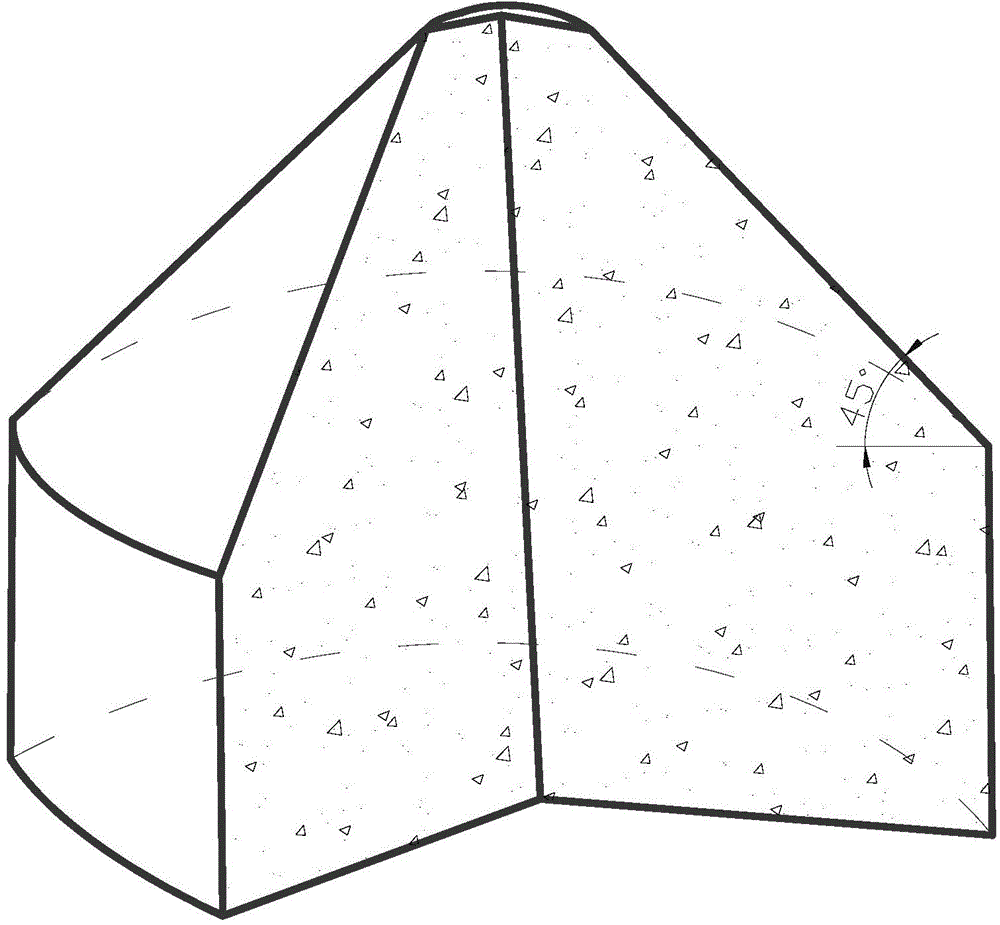

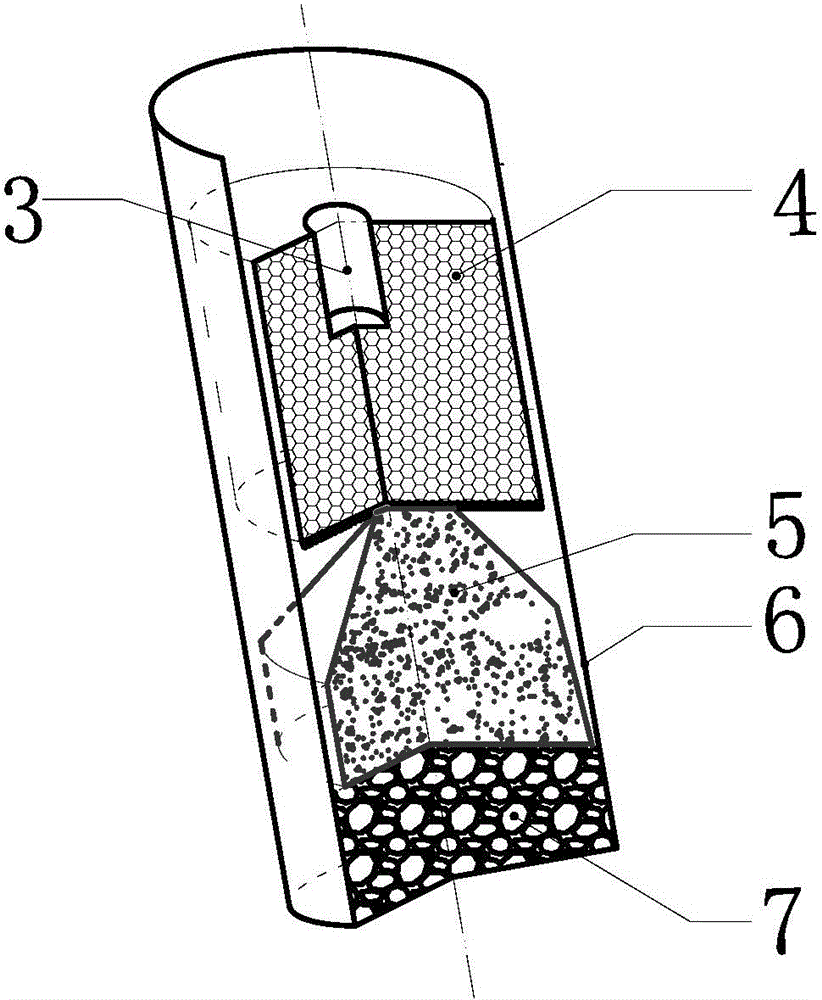

[0029] The rock foundation blasting excavation project of a hydropower station needs to ensure the flatness of the foundation surface. The deep hole step blasting is adopted. In order to realize rapid construction, the vertical hole is required to be blasted at one time. In order to obtain a relatively flat foundation surface and ensure the flatness of the hole bottom, it is necessary to install the hole bottom energy-dissipating base. A high-wave impedance concrete is designed to improve the energy utilization efficiency of drilling and blasting and the flatness of the bottom of the hole. The requirements are as follows: the density reaches 3500-4500kg / m 3 , the longitudinal wave velocity reaches 3900-4200m / s in 7 days, and the longitudinal wave velocity reaches 4300-4600m / s in 28 days. It is known that the diameter of the blast hole during the excavation process is 105mm, and the technical requirement is that the average fluctuation difference is not greater than 0.1m

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com