Magnetically separable solid-phase polymerization inhibitor and its preparation method and application

A polymerization inhibitor and polymerization inhibition technology, applied in chemical instruments and methods, purification/separation of hydrocarbons, separation/purification of carboxylic acid compounds, etc., can solve the problems of large environmental pollution and difficulty in separation, and achieve low synthesis cost , reduce the polymerization rate, the effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

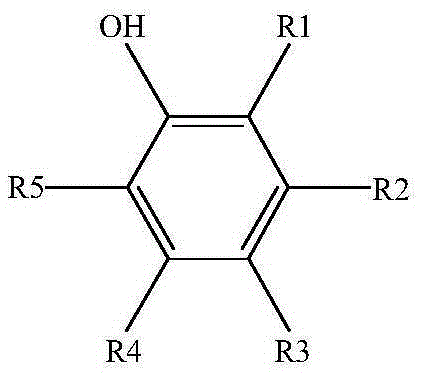

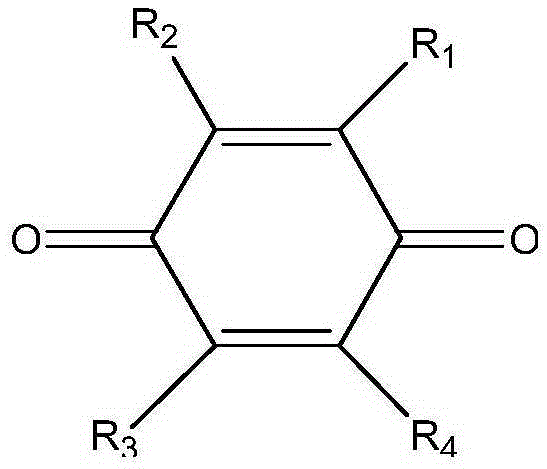

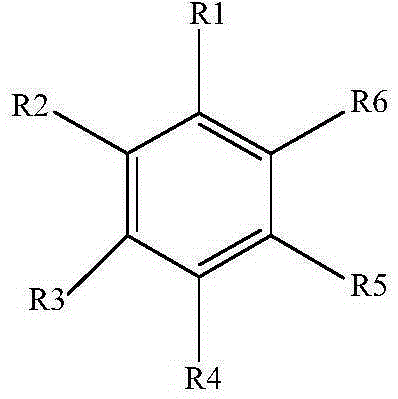

Method used

Image

Examples

Embodiment 1

[0043] p-Hydroxybenzaldehyde inhibitor preparation method:

[0044]Disperse the magnetic powder in a chitosan solution with a mass fraction of 1.5%, add paraffin and ethyl acetate to make a fine emulsion, adjust the pH=5, add the crosslinking agent formaldehyde, adjust the pH=9, stir for 15 minutes, adjust the pH =5, add glutaraldehyde, adjust the pH=9, adjust the temperature to 30-80° C., and keep stirring for 1-12 hours to obtain chitosan-coated functionalized microspheres. Disperse chitosan functional microspheres containing amino groups on the surface in an aqueous solution, add p-hydroxybenzaldehyde, adjust pH=8 and temperature 45°C, and continue stirring for 6 hours to obtain the product.

[0045] Add 0.6 mg of the above-mentioned polymerization inhibitor to 3 grams of styrene system, and the composition of the polymerization inhibitor is: 50% gamma-Fe 3 o 4 , 40% linking component (35% chitosan oligosaccharide and 5% glutaraldehyde), 10% inhibitory component (p-hydrox...

Embodiment 2

[0049] Add 0.6 mg of the polymerization inhibitor described in this patent to 3 grams of styrene system, by weight percentage, the composition of the polymerization inhibitor is: 60% gamma-Fe 2 o 3 , 30% connection component (silane coupling agent KH550), 10% polymerization inhibitor component (p-hydroxybenzaldehyde), the implementation method is the same as in Example 1. The styrene polymerization rate was 0.5% by mass.

Embodiment 3

[0053] Add 0.6 mg of the polymerization inhibitor described in this patent to 3 grams of styrene system, by weight percentage, the composition of the polymerization inhibitor is: 40% gamma-Fe 2 o 3 , 40% linking component (L glutamic acid), 20% polymerization inhibitory component (p-Hydroxybenzaldehyde), implementation method is the same as embodiment 1. The polymerization rate of styrene was 0.3% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com