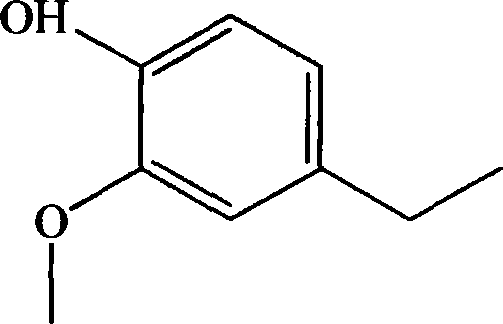

A kind of method for preparing 4-ethyl-2-methoxyphenol by catalytic pyrolysis of biomass

A methoxyphenol, catalytic pyrolysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, ether preparation and other directions, can solve the problems of complex extraction process steps, many waste liquids that are difficult to handle, no economy, and the like, To achieve the effect of simple composition, low requirements for equipment and reaction conditions, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 0.50g of palladium nitrate dihydrate (Pd(NO 3 ) 2 2H 2 O) Dissolve in 100mL deionized water, stir until completely dissolved, add 8.00g MCM-41 to the solution, slowly drop ammonia water (25%) into the mixed solution under stirring until the pH value reaches 10, and then continue Stir at room temperature for 12h. After the stirring, the solid was filtered, dried at 100°C for 3h, and then reduced at 280°C for 3h (programmed temperature: 2°C / min) in an atmosphere of hydrogen (6% hydrogen, nitrogen as protective gas). 8.01 g of Pd / MCM-41 were obtained with a Pd loading of 2%.

[0027] Take 2g of the above catalyst, grind it to a particle size of less than 0.5mm, take 10g of larch wood as a raw material, grind it to a particle size of less than 0.3mm, mix the two mechanically, and quickly pyrolyze them at 290°C for 20s under a nitrogen atmosphere to obtain a liquid product Yield 36.5%, analyze wherein the content of 4-ethyl-2-methoxyphenol by gas chromatography, ca...

Embodiment 2

[0029] Take 5g of the catalyst in the above example 1, grind it to a particle size of less than 0.5mm, take 10g of spruce wood as a raw material, grind it to a particle size of less than 0.3mm, mix the two mechanically and rapidly pyrolyze them at 330°C under a nitrogen atmosphere 15s, the obtained liquid yield was 42.8%, and the content of 4-ethyl-2-methoxyphenol was analyzed by gas chromatography, and the yield of 4-ethyl-2-methoxyphenol was calculated to be 2.3%; The content of 4-ethyl-2-methoxyphenol in the organic liquid product (excluding water) was 11.0%.

Embodiment 3

[0031] Weigh 1.25g of palladium nitrate dihydrate (Pd(NO 3 ) 2 2H 2 O) Dissolve in 100mL deionized water, stir until completely dissolved, add 7.80g SBA-15 to the solution, slowly drip ammonia water (25%) into the mixed solution under stirring until the pH value reaches 9, and then continue Stir at room temperature for 12h. After the stirring, the solid was filtered, dried at 100°C for 3h, and then reduced at 280°C for 3h (programmed temperature: 2°C / min) in an atmosphere of hydrogen (6% hydrogen, nitrogen as protective gas). 8.05 g of Pd / SBA-15 with a Pd loading of 5% was obtained.

[0032] Take 2g of the above catalyst, grind it to a particle size of less than 0.5mm, take 10g of cedar wood as a raw material, grind it to a particle size of less than 0.3mm, mix the two mechanically, and rapidly pyrolyze them at 300°C for 15s under a nitrogen atmosphere to obtain a liquid product Yield 36.2%, analyze wherein the content of 4-ethyl-2-methoxyphenol by gas chromatography, calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com