Extraction-separation method and application of corilagin

A separation method and technology for extracting liquid, applied in the field of biomedicine, can solve the problems of insufficient storage and preservation technology, unutilized fruit cores, restrictions on fresh fruit consumption, etc., and achieve the effects of reducing oil-soluble components, being easy to recover, and simplifying processing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

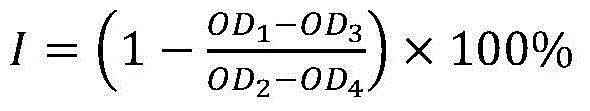

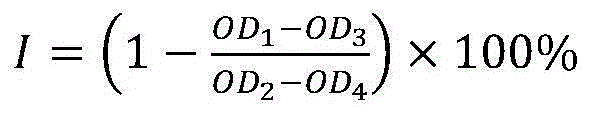

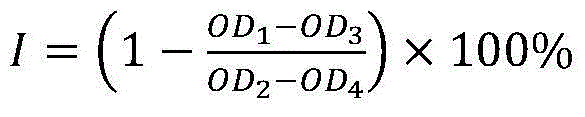

Embodiment 1

[0029](1) Extraction of Corilagin: first collect the discarded fruit cores of longan processing in the longan fruit field, dry them naturally, and pulverize them through a 20-mesh sieve to obtain longan fruit core powder. Take 100 g of longan fruit core powder in a 2000 mL three-necked flask, Then add 1500mL of anhydrous acetone, install a stirring device with a seal, plug the other two ports tightly, stir at room temperature for pretreatment for 1h, let stand for 1h, and precipitate the upper layer (basically clear), discard the upper layer; add 1500mL 80% for the second time Acetone aqueous solution, equipped with a thermometer and a reflux device, placed in a water bath to heat and control the solution temperature to 55°C, stirred for 2 hours, then stood still for 1 hour, precipitated the upper layer and filtered it under vacuum at 0.04-0.05MPa to obtain the second filtrate; the third Add 1500mL 60% acetone aqueous solution for the first time, and the operation is the same a...

Embodiment 2

[0037] (1) Extraction of Corilagin: first collect the discarded fruit cores of longan processing in the longan fruit field, dry them naturally, and pulverize them through a 20-mesh sieve to obtain longan fruit core powder. Take 100 g of longan fruit core powder in a 2000 mL three-necked flask, Then add 1500mL of anhydrous acetone, install a stirring device with a seal, plug the other two ports tightly, stir at room temperature for pretreatment for 1h, let stand for 1h, and precipitate the upper layer (basically clear), discard the upper layer; add 1500mL 80% for the second time Acetone aqueous solution, equipped with a thermometer and a reflux device, placed in a water bath to heat and control the solution temperature to 55°C, stirred for 2 hours, then stood still for 1 hour, precipitated the upper layer and filtered it under vacuum at 0.04-0.05MPa to obtain the second filtrate; the third Add 1500mL 60% acetone aqueous solution for the first time, and the operation is the same ...

Embodiment 3

[0045] (1) Extraction of Corilagin: first collect the discarded fruit cores of longan processing in the longan fruit field, dry them naturally, and pulverize them through a 20-mesh sieve to obtain longan fruit core powder. Take 100 g of longan fruit core powder in a 2000 mL three-necked flask, Then add 1500mL of anhydrous acetone, install a stirring device with a seal, plug the other two ports tightly, stir at room temperature for pretreatment for 1h, let stand for 1h, and precipitate the upper layer (basically clear), discard the upper layer; add 1500mL 80% for the second time Acetone aqueous solution, equipped with a thermometer and a reflux device, placed in a water bath to heat and control the solution temperature to 55°C, stirred for 2 hours, then stood still for 1 hour, precipitated the upper layer and filtered it under vacuum at 0.04-0.05MPa to obtain the second filtrate; the third Add 1500mL 60% acetone aqueous solution for the first time, and the operation is the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com