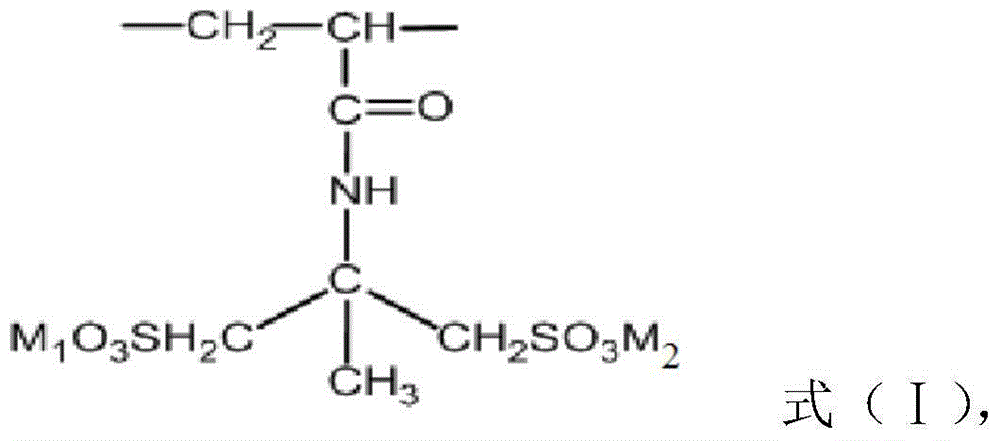

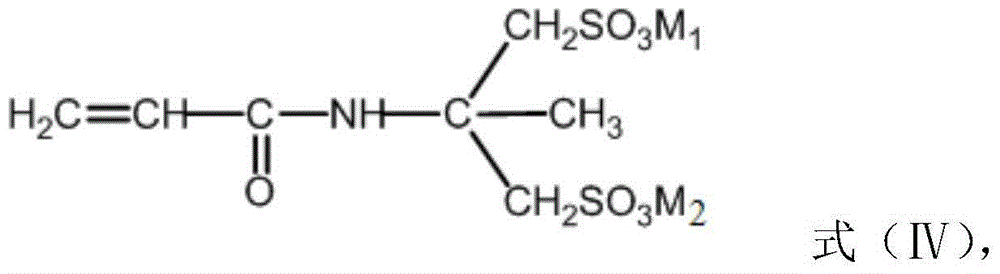

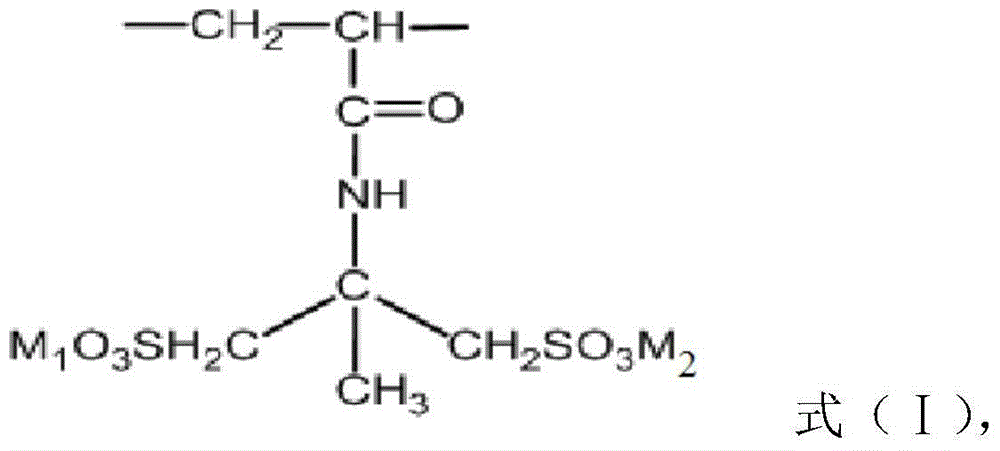

Acrylamide copolymer and preparation method and application thereof

A technology of acrylamide copolymer and acrylamide copolymerization, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature resistance and salt resistance, and achieve the goal of improving hydrolysis resistance and salt resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment is used to illustrate the acrylamide copolymer provided by the present invention and its preparation method

[0059] Add 927.09 kg of acrylamide (AM) and 1079.26 kg of acrylamide monomer C (among them, M 1 and M 2 Same, each is sodium), 8025.4 kg of deionized water, under stirring, control the temperature of the solution with frozen brine to -7°C, and add sodium hydroxide to adjust the pH to 5. Pump the monomer solution into the polymerization tank, add 20.06 grams of water-soluble azo initiator 2,2'-azo(2-amidinopropane) dihydrochloride and reducing agent N,N,N',N' - 20.06 grams of tetramethylethylenediamine, deoxygenated by passing high-purity nitrogen gas for 0.5 hours, adding 20.06 grams of sodium bisulfite and 20.06 grams of ammonium persulfate, continuing to pass nitrogen until the thermocouple in the polymerization kettle starts to heat up, and the reaction time is 8 hours. Open the ball valve at the bottom of the reactor, press out the obtained...

Embodiment 2

[0061] Add 1108.85 kilograms of AM and 145.2 kilograms of acrylamide monomer C (wherein, M 1 and M 2 Same, each is potassium), 2926.11 kg of deionized water, under stirring state, control the temperature of the solution with refrigerated brine to 15°C, and add sodium hydroxide to adjust the pH to 10. Pump the monomer solution into the polymerization tank, add 627.03 grams of water-soluble azo initiator 2,2'-azo(2-amidinopropane) dihydrochloride and reducing agent N,N,N',N' - 627.03 grams of tetramethylethylenediamine, deoxygenated by passing high-purity nitrogen gas for 0.5 hours, adding 627.03 grams of sodium bisulfite and 627.03 grams of ammonium persulfate, continuing to pass nitrogen until the thermocouple in the polymerization kettle starts to heat up, and the reaction time is 3 hours. Open the ball valve at the bottom of the reactor, press out the obtained copolymer colloid with 0.3MPa compressed air, and granulate it into small colloids of 4-6 mm by a granulator. Knea...

Embodiment 3

[0063] This example is used to illustrate the acrylamide copolymer provided by the present invention and its preparation method.

[0064] Add 1080.4 kilograms of AM and 277.6 kilograms of temperature-resistant and salt-resistant monomer C (among them, M 1 and M 2 Not the same, M 1 for sodium, M 2 Potassium), 4074 kg of deionized water, under stirring, control the temperature of the solution with refrigerated saline at 0°C, and add sodium hydroxide to adjust the pH to 10. Pump the monomer solution into the polymerization tank, add 200 grams of water-soluble azo initiator 2,2'-azo(2-amidinopropane) dihydrochloride and reducing agent N,N,N',N' - 200 grams of tetramethylethylenediamine, deoxygenated by high-purity nitrogen for 0.5 h, adding 150 grams of sodium bisulfite and 200 grams of ammonium persulfate, and continuing to pass nitrogen until the thermocouple in the polymerization kettle starts to heat up, and the reaction time is 8 hours. Open the ball valve at the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com