MBS resin with impact resistance, stress crease and fold resistance and excellent transparency

A stress-resistant and impact-resistant technology, applied in the field of MBS resin, can solve problems such as reduced transparency, and achieve the effects of improving light transmittance, improving impact strength, and improving stress whitening resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] According to the following steps, the impact resistance of the present invention, stress-resistant whitening, MBS resin with high light transmittance are prepared

[0053] ①. Preparation of seed emulsion:

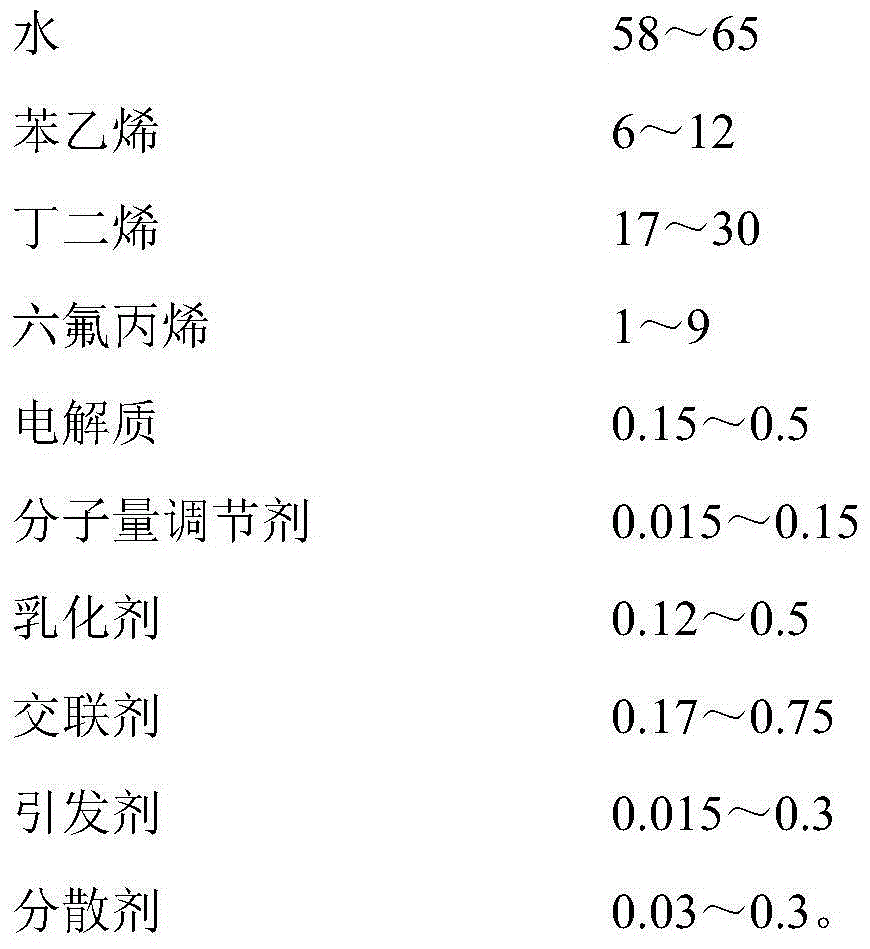

[0054] a. Feed and heat up

[0055] In the seed emulsion polymerization reactor, drop into 60 parts by weight of deionized water, 0.2 parts by weight of emulsifier potassium stearate, 0.08 parts by weight of dispersant potassium perfluoroalkyl ether carboxylate, 0.3 parts by weight of electrolyte potassium chloride, 0.04 parts by weight of molecular weight regulator dodecyl mercaptan, 0.3 parts by weight of diallyl phthalate crosslinking agent, 12 parts by weight of styrene, 0.08 parts by weight of initiator potassium persulfate, replace the still with high-purity nitrogen After air, add 17 parts by weight of butadiene and 6 parts by weight of hexafluoropropylene; stir and mix for 15 to 30 minutes, slowly raise the temperature, and raise the temperature to 48°C in h...

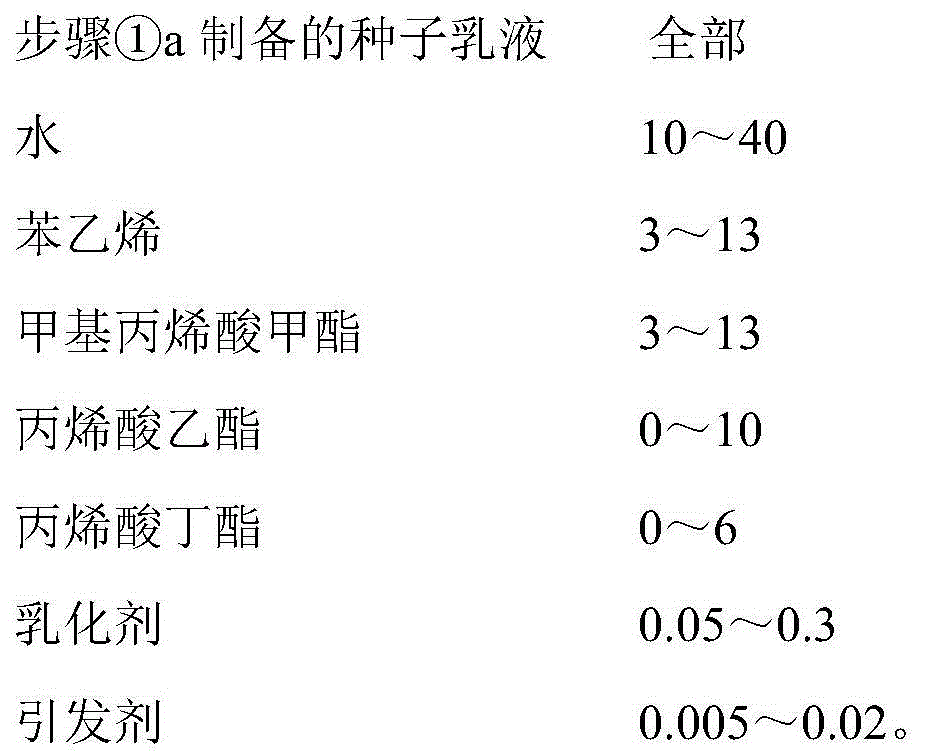

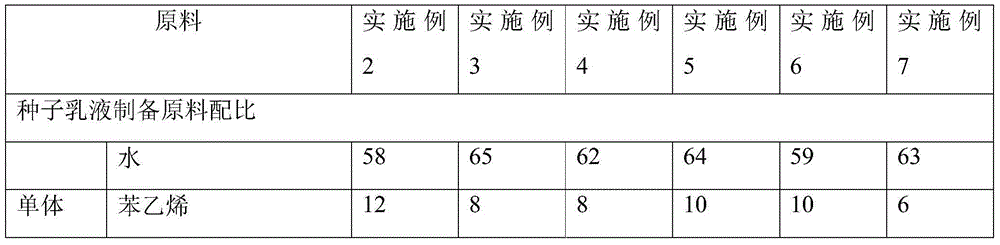

Embodiment 2~7

[0072] According to the method and steps of Example 1, the MBS resin with high impact resistance, stress whitening resistance and light transmittance of the present invention is prepared according to the raw material formula in Table 1

[0073] Table 1

[0074]

[0075]

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com