Plastic material capable of releasing anions and preparation method of plastic material

A technology of plastic profiles and negative ions, applied in the field of plastic profiles that can release negative ions and its preparation, can solve problems such as exceeding the standard and not meeting environmental protection requirements, and achieve the effect of good tensile performance and good heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

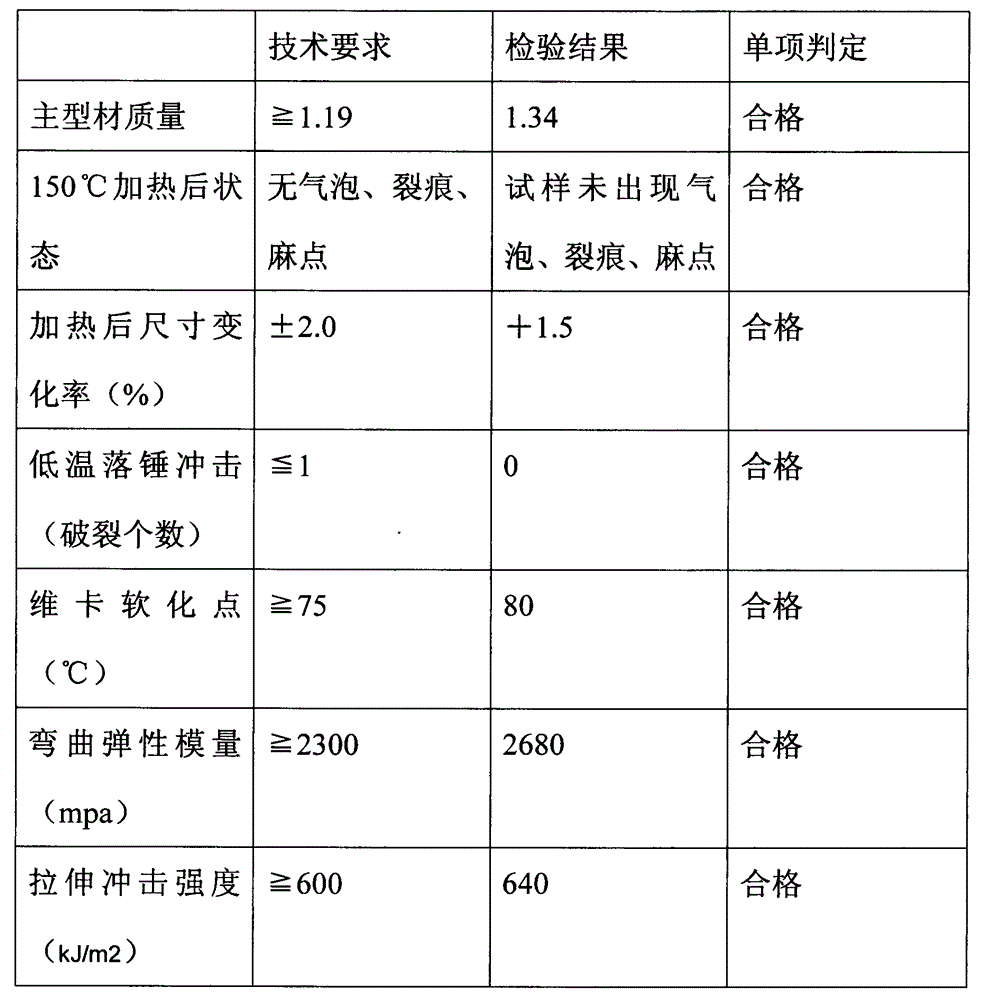

Image

Examples

Embodiment Construction

[0011] The environmentally friendly profile formula and its preparation method are composed of the following raw materials in parts by weight: polyvinyl chloride resin 90, negative ion additive 5, calcium carbonate powder 25, sepiolite powder 10, ACR additive 1.5, titanium dioxide 3.8, stearic acid 0.08, lead-free calcium zinc heat stabilizer 3.3, polyethylene wax 0.35, ultraviolet absorber 0.12, ultramarine blue 0.03. Add filler calcium carbonate, sepiolite powder, ACR additives to the mixed polyvinyl chloride resin and negative ion additive recycled materials, then add lubricant stearic acid, polyethylene wax, then add ultraviolet absorber, titanium dioxide, ultramarine blue, and finally Add lead-free calcium-zinc heat stabilizer, put them together in a high-speed mixer at 132-138°C for high-temperature mixing for 9-10 minutes, then place them in a low-speed mixer to cool to 35-45°C, and then mix the mixture Carry out extrusion molding and cut into finished products.

[001...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com