Waterborne polyurethane coating and preparation method thereof

A technology of water-based polyurethane and water-based polyurethane adhesive, which is applied in the direction of polyurea/polyurethane coatings and coatings, can solve the problems of poor heat resistance and unstable dispersion of water-based polyurethane coatings, and achieve good heat resistance, easy storage and transportation. The effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

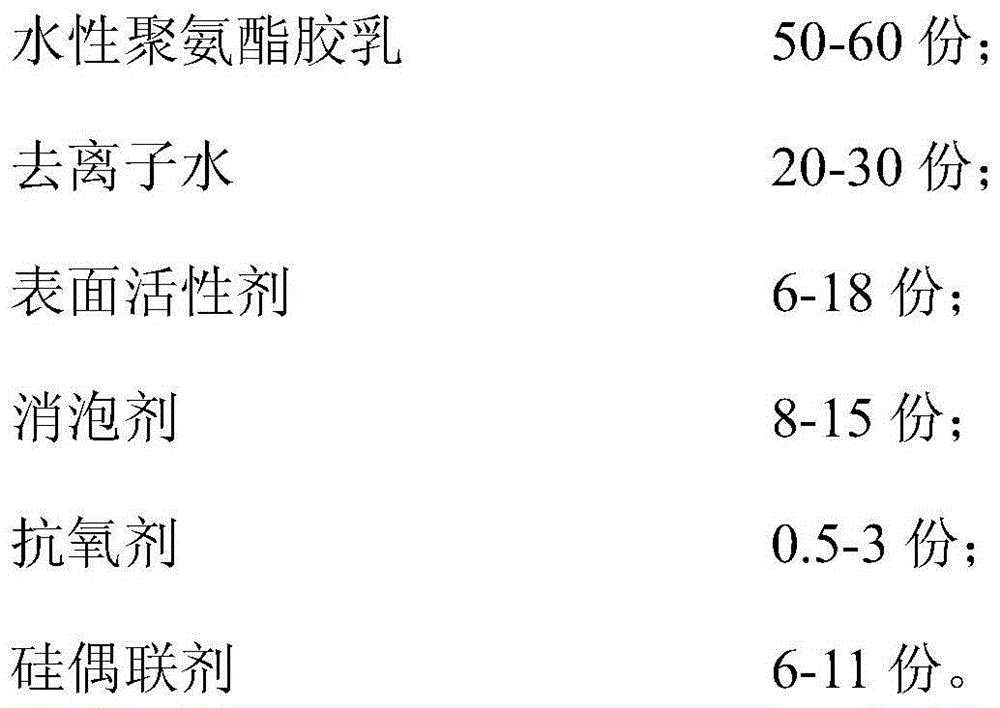

[0034] The invention provides a water-based polyurethane coating and a preparation method thereof, which consist of the following components in parts by weight:

[0035]

[0036] The preparation technology of waterborne polyurethane coating of the present invention is as follows:

[0037] (1) In a four-necked flask equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser, according to the molar ratio isophorone diisocyanate (IPDI): ethylene glycol: the mole of xylene=4:3:0.5 For comparison, add phorone diisocyanate (IPDI), ethylene glycol, and xylene to a four-necked flask respectively, and continuously feed argon gas into it, and react for 4 hours at normal temperature;

[0038] (2) Slowly add 0.1ml of dibutyltin dilaurate dropwise, the temperature is slowly raised to 60°C, react for 2 hours, and remove excess solvent by rotary evaporation to obtain water-based polyurethane latex;

[0039] (3) Add the above-mentioned ingredients except the silicon...

Embodiment 2

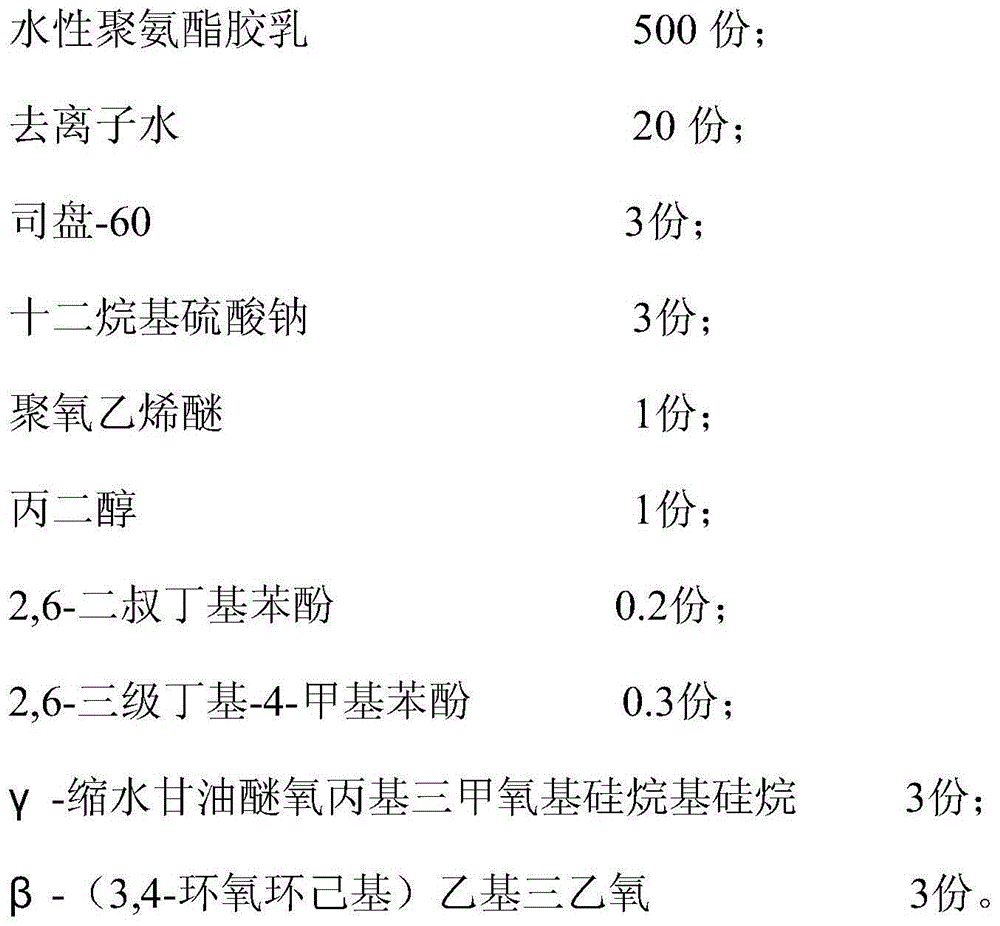

[0041] The invention provides a water-based polyurethane coating and a preparation method thereof, which consist of the following components in parts by weight:

[0042]

[0043] The preparation technology of waterborne polyurethane coating of the present invention is as follows:

[0044] (1) In the four-necked flask that stirrer, thermometer, dropping funnel, reflux condenser are installed, according to molar ratio isophorone diisocyanate (IPDI): ethylene glycol: the mole of xylene=4.5:3.5:0.6 For comparison, add phorone diisocyanate (IPDI), ethylene glycol, and xylene to a four-neck flask respectively, and continuously feed argon gas into it, and react for 4.5 hours at room temperature;

[0045] (2) Slowly add 0.1-0.5ml of dibutyltin dilaurate dropwise, the temperature rises slowly to 65°C, react for 3 hours, and remove excess solvent by rotary evaporation to obtain water-based polyurethane latex;

[0046] (3) Add the above-mentioned ingredients except the silicon coupli...

Embodiment 3

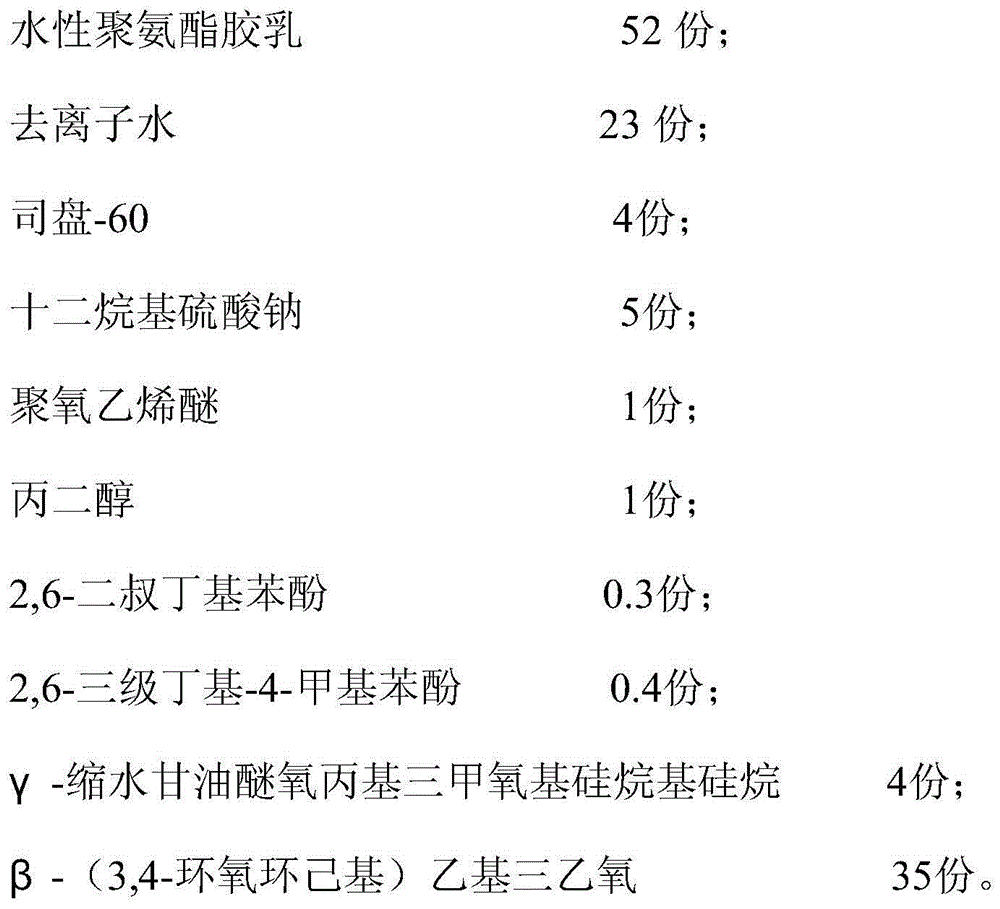

[0048] The invention provides a water-based polyurethane coating and a preparation method thereof, which consist of the following components in parts by weight:

[0049]

[0050] The preparation technology of waterborne polyurethane coating of the present invention is as follows:

[0051] (1) In the four-necked flask that stirrer, thermometer, dropping funnel, reflux condenser are installed, according to molar ratio isophorone diisocyanate (IPDI): ethylene glycol: the mole of xylene=4.8:3.5:0.9 Than, respectively add phorone diisocyanate (IPDI), ethylene glycol, and xylene into a four-necked flask, and continuously feed argon gas, and react at room temperature for 5 hours;

[0052] (2) Slowly add 0.4ml of dibutyltin dilaurate dropwise, the temperature rises slowly to 75°C, react for 3 hours, and remove excess solvent by rotary evaporation to obtain water-based polyurethane latex;

[0053] (3) Add the above-mentioned ingredients except the silicon coupling agent into the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com