Preparation method of golden yellow ceramic paint for subway stations

A technology for ceramic coatings and subway stations, applied in coatings and other directions, can solve problems such as inability to solve traffic congestion, and achieve the effect of reducing activation energy, realizing the protection process, and avoiding difficult storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

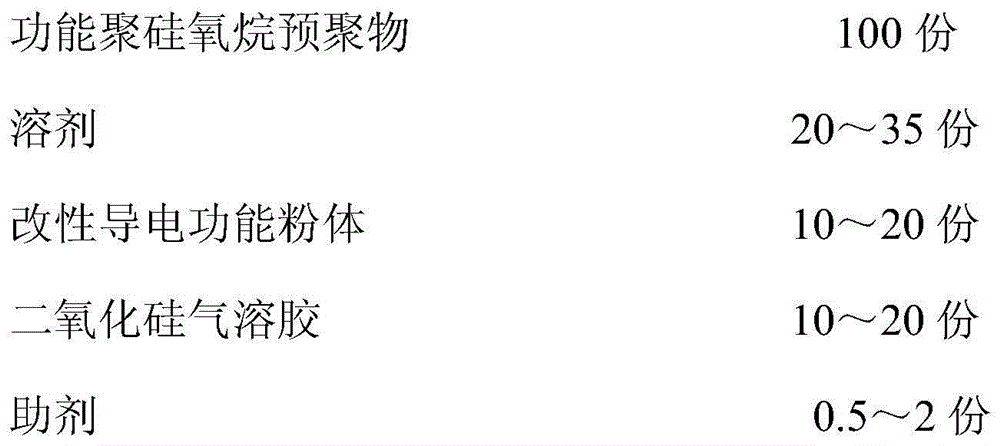

[0037] A kind of golden yellow ceramic coating that is used for subway station, its raw material component parts by weight are:

[0038]

[0039] A preparation method for a golden yellow ceramic coating for a subway station, comprising the following steps:

[0040] 1. Preparation of functional polysiloxane prepolymer: Four needle-shaped zinc oxide whiskers are ultrasonically dispersed in a mixed solvent of deionized water and alcohol. After the dispersion is completed, a composite catalyst is added to the dispersion to adjust the The pH is 2.0-4.0, then add siloxane monomer, and the molar ratio of siloxane monomer to deionized water is 1:5, mix under normal conditions, and then ultrasonicate at a temperature of 35-50°C, Obtain the required functional polysiloxane prepolymer.

[0041] The center body diameter of the tetraacicular zinc oxide whiskers is 0.7-1.0 μm, the root diameter of the needles is 0.5-1.5 μm, the length of the needles is 3-5 μm, and the ultrasonic dispers...

Embodiment 2

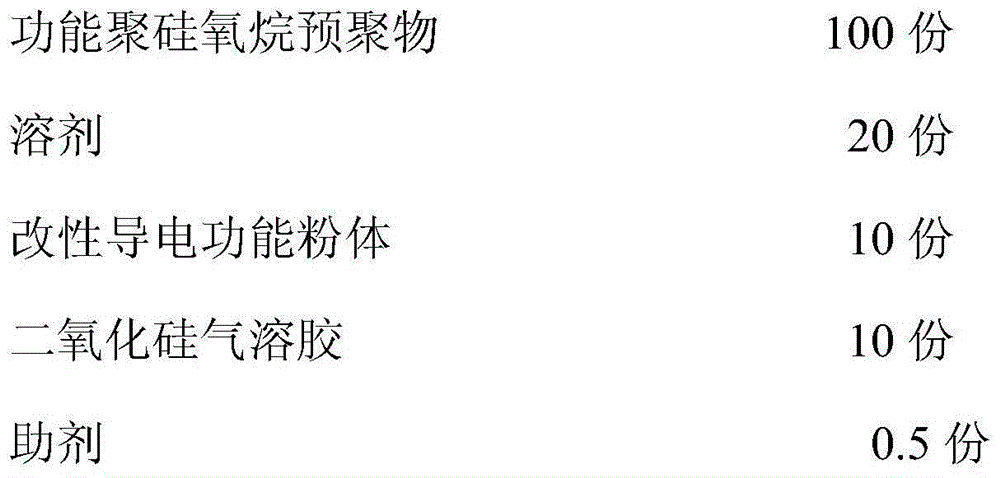

[0050] A kind of golden yellow ceramic coating that is used for subway station, its raw material component parts by weight are:

[0051]

[0052] A preparation method for a golden yellow ceramic coating for a subway station, comprising the following steps:

[0053] 1. Preparation of functional polysiloxane prepolymer: Four needle-shaped zinc oxide whiskers are ultrasonically dispersed in a mixed solvent of deionized water and alcohol. After the dispersion is completed, a composite catalyst is added to the dispersion to adjust the The pH is 2.0-4.0, then add siloxane monomer, and the molar ratio of siloxane monomer to deionized water is 1:10, mix under normal conditions, and then ultrasonicate at a temperature of 35-50°C, Obtain the required functional polysiloxane prepolymer.

[0054] The center body diameter of the tetraacicular zinc oxide whiskers is 0.7-1.0 μm, the root diameter of the needles is 0.5-1.5 μm, the length of the needles is 3-5 μm, and the ultrasonic disper...

Embodiment 3

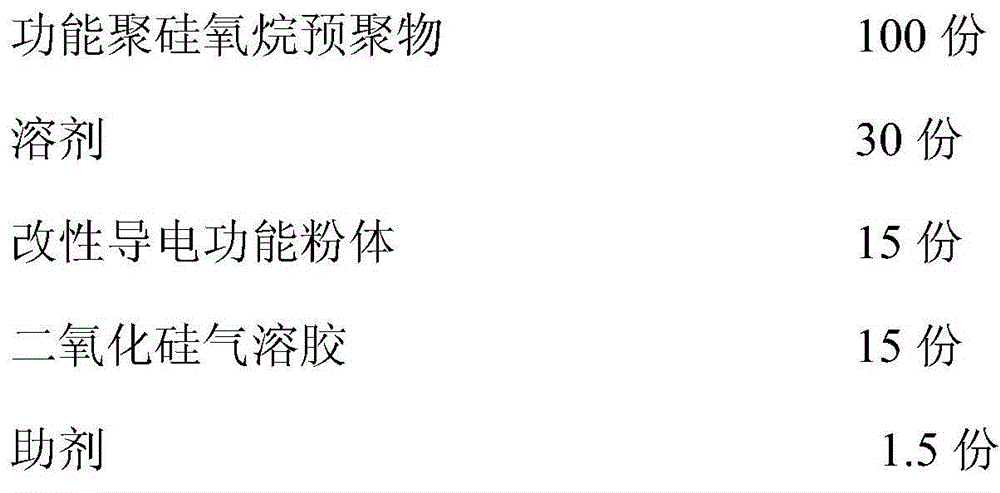

[0063] A kind of golden yellow ceramic coating that is used for subway station, its raw material component parts by weight are:

[0064]

[0065] A preparation method for a golden yellow ceramic coating for a subway station, comprising the following steps:

[0066]1. Preparation of functional polysiloxane prepolymer: Four needle-shaped zinc oxide whiskers are ultrasonically dispersed in a mixed solvent of deionized water and alcohol. After the dispersion is completed, a composite catalyst is added to the dispersion to adjust the The pH is 2.0-4.0, then add siloxane monomer, and the molar ratio of siloxane monomer to deionized water is 1:15, mix under normal conditions, and then ultrasonicate at a temperature of 35-50°C, Obtain the required functional polysiloxane prepolymer.

[0067] The center body diameter of the tetraacicular zinc oxide whiskers is 0.7-1.0 μm, the root diameter of the needles is 0.5-1.5 μm, the length of the needles is 3-5 μm, and the ultrasonic dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com