Method for preparing polyethylene type adhesive resin for multilayer co-extrusion barrier package

A multi-layer co-extrusion and bonding resin technology, which is applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problem of excessive tensile stress and strain of bonding strength, affecting product quality and production efficiency, and delamination at edges and corners and other problems, to achieve excellent bonding performance, improve product quality and production efficiency, and achieve lasting and stable bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

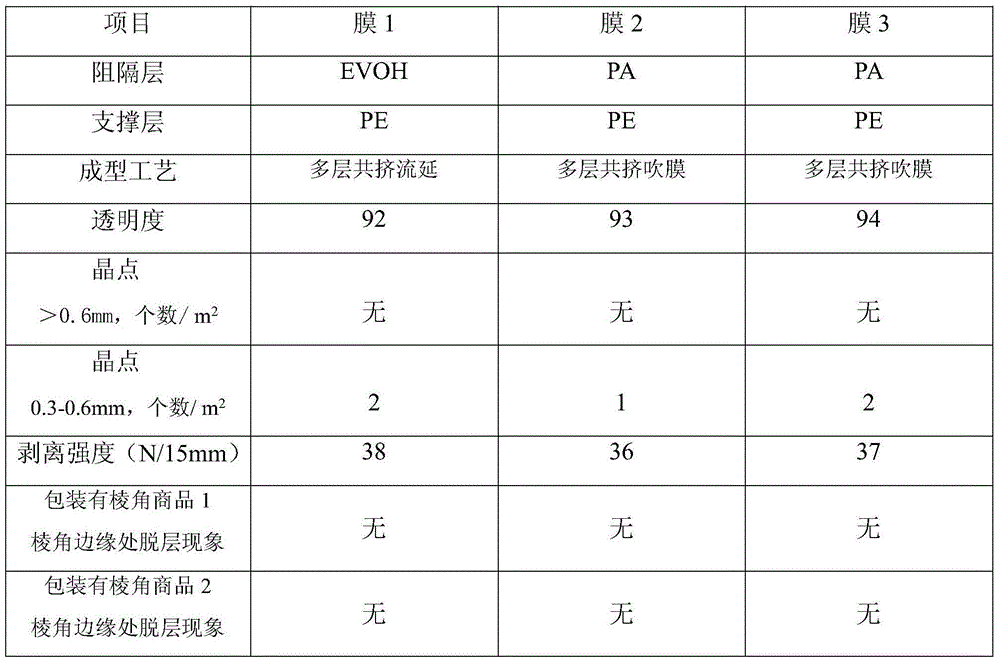

Examples

Embodiment 1

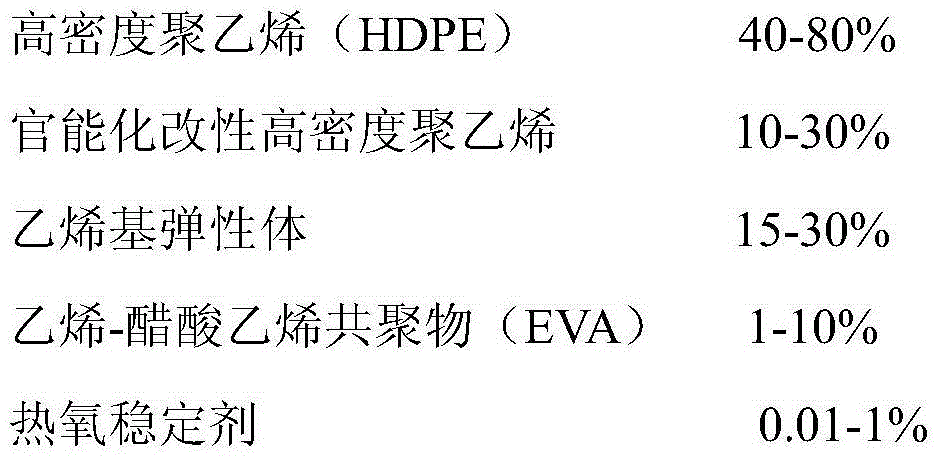

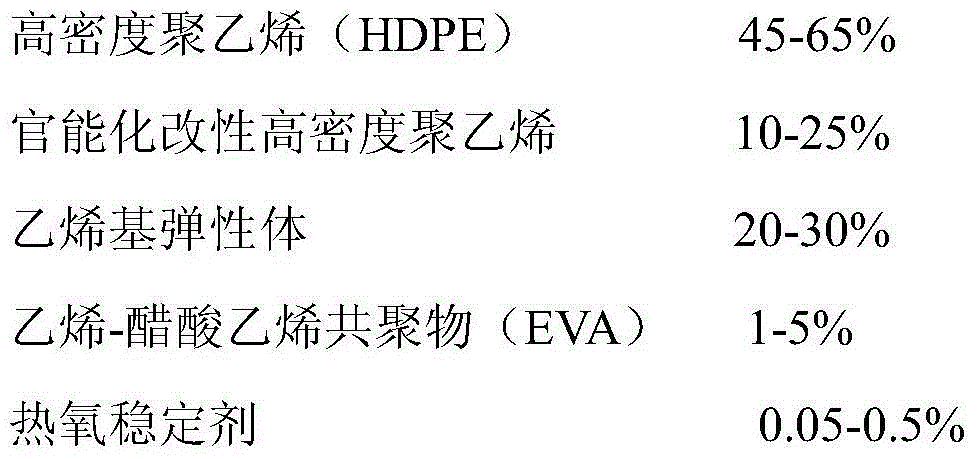

[0025] The raw material formula (the following proportions are weight percentages) of the polyethylene adhesive resin composition for multilayer co-extruded barrier packaging is as follows:

[0026] 63% HDPE

[0027] 15% functionalized modified high density polyethylene

[0028] 20% ethylene-butylene copolymer elastomer

[0029] 2% ethylene-vinyl acetate copolymer

[0030] 0.08% thermal oxygen stabilizer

[0031] The above-mentioned components are extruded and granulated by plasticizing and blending with a twin-screw extruder. The length-to-diameter ratio of the extruder is L / D=40:1, and the processing temperature is 150-230°C. Polyethylene type adhesive resin for multilayer coextruded barrier packaging.

Embodiment 2

[0033] The raw material formula (the following proportions are weight percentages) of the polyethylene adhesive resin composition for multilayer co-extruded barrier packaging is as follows:

[0034] 54.5% HDPE

[0035] 18% functionalized modified high density polyethylene

[0036] 25% ethylene-octene copolymer elastomer

[0037] 2.5% ethylene-vinyl acetate copolymer

[0038] 0.1% thermal oxygen stabilizer

[0039] The above-mentioned components are extruded and granulated by plasticizing and blending with a twin-screw extruder. The length-to-diameter ratio of the extruder is L / D=40:1, and the processing temperature is 150-230°C. Polyethylene type adhesive resin for multilayer coextruded barrier packaging.

Embodiment 3

[0041] The raw material formulation (the following proportions are weight percentages) of the polyethylene adhesive resin composition for multilayer co-extruded barrier packaging is as follows:

[0042] 50% HDPE

[0043] 20% functionalized modified high density polyethylene

[0044] 27% ethylene-butylene copolymer elastomer

[0045] 3% ethylene-vinyl acetate copolymer

[0046] 0.12% thermal oxygen stabilizer

[0047] The above-mentioned components are extruded and granulated by plasticizing and blending with a twin-screw extruder. The length-to-diameter ratio of the extruder is L / D=40:1, and the processing temperature is 150-230°C. Polyethylene type adhesive resin for multilayer coextruded barrier packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com