Extraction method of soybean oil body having high oxidation resistance

A technology of soybean oil body and extraction method, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problems of easy volatility, emulsifier instability, toxicity, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Specific Embodiment 1: This embodiment provides a method for extracting soybean oil bodies with high oxidation resistance. It uses soybean seeds as raw materials and extracts them by soaking, grinding, filtering, centrifuging, homogenizing and other processes. The specific steps as follows:

[0031] (1) Soaking: Soak 80g of soybean seeds in 450ml of water for 12 h before use.

[0032] (2) Grinding: Add the seeds with full particles after soaking into a tissue grinder, and grind at 14000 rpm for 2 min. The grinding medium was 1 L of buffer containing 0.6 M sucrose and 10 mM sodium phosphate, pH 7.5.

[0033] (3) Filtration: The homogenate is filtered through three layers of cheesecloth.

[0034] (4) Centrifugal:

[0035] a. Collect the filtrate for sub-packaging and centrifugation, place every 150-200 ml of filtrate at the bottom of a 500-ml centrifuge tube, and use 150-200 ml of flotation medium for each tube (buffer containing 0.4 M sucrose and 10 mM sodium phosphat...

specific Embodiment approach 2

[0044] Specific embodiment two: this embodiment is used as following explanation to the grease body that specific embodiment one prepares:

[0045] 1. Grease body spray drying

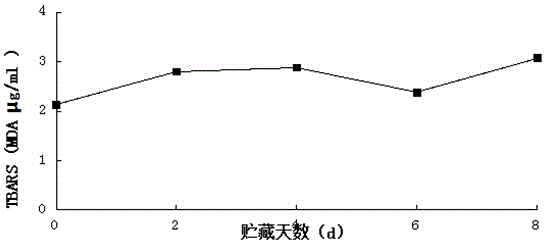

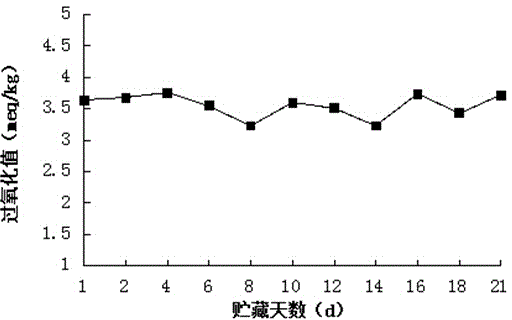

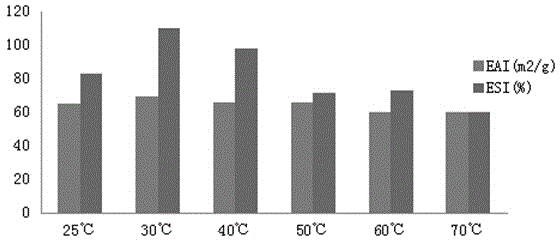

[0046] Soybean oil bodies contain a large amount of higher unsaturated fatty acids, especially oleic acid and linoleic acid. However, unsaturated fatty acids in soybean oil body are prone to oxidation, which reduces its nutritional value, and at the same time generates some substances, which have adverse effects on human health. The microencapsulation of soybean oil bodies can effectively avoid the oxidative deterioration of unsaturated fatty acids in soybean oil bodies and prolong the storage period of soybean oil bodies.

[0047] Microencapsulation process: soybean oil body emulsion + wall material → constant temperature stirring → homogenization → emulsion → spray drying → finished microcapsules.

[0048] Weigh a certain amount of soybean protein isolate and maltodextrin (the ratio of soybean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com