Method for nondestructively transferring graphene from metal surface to surface of target substrate

A graphene surface and target substrate technology, applied in the field of materials, can solve problems such as resource consumption and graphene damage, and achieve the effects of improving quality, reducing damage, and efficient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

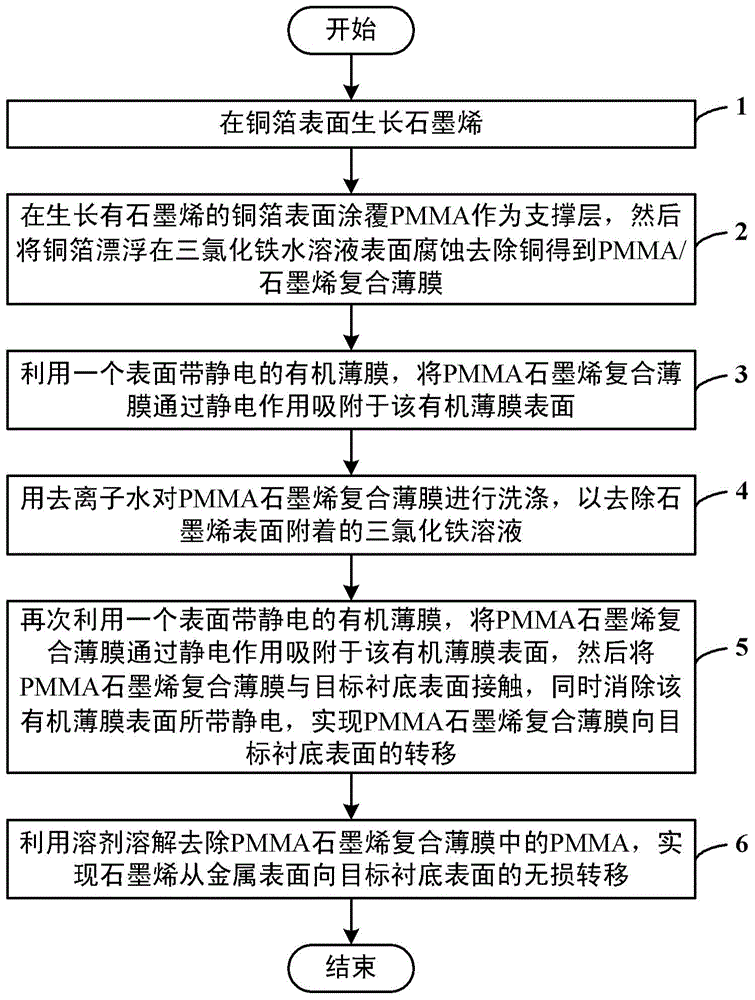

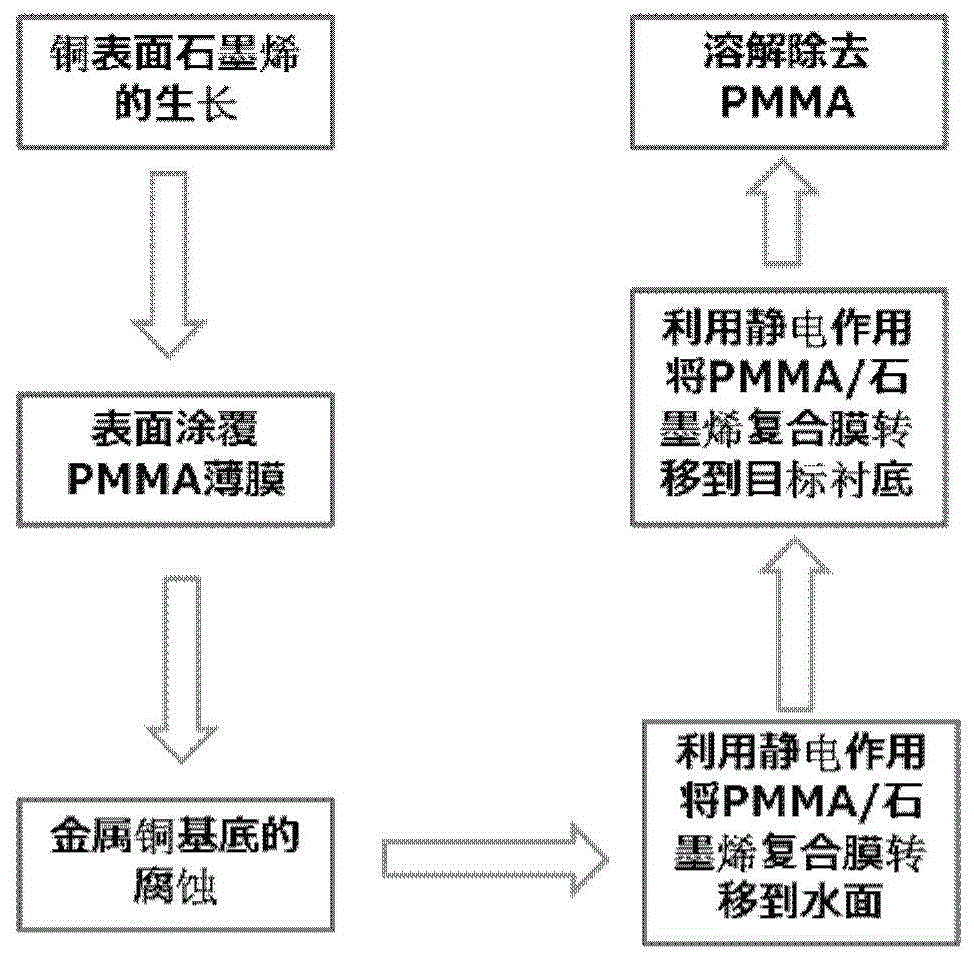

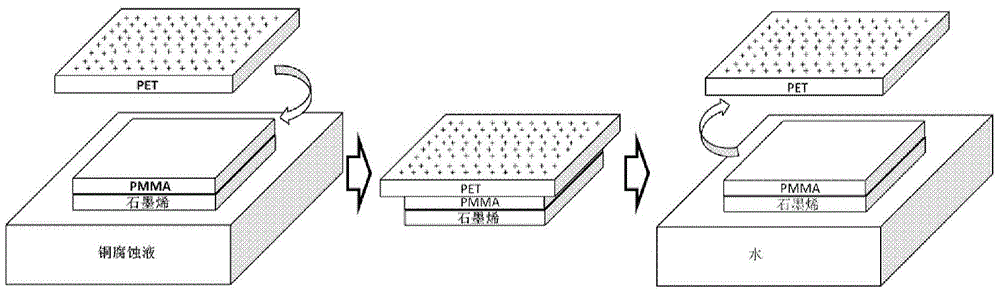

[0044] Embodiment 1: The transfer of CVD graphene on the surface of copper foil to the surface of glass is realized by electrostatic interaction.

[0045] Put the copper foil into a CVD furnace, in a mixed atmosphere of 10sccm hydrogen and 2sccm methane, use chemical vapor deposition to grow graphene on the copper surface at a high temperature of 1000°C; coat PMMA on the surface of the copper foil with graphene grown; Copper foil floats on the surface of ferric chloride aqueous solution and corrodes to remove metal copper to obtain PMMA / graphene composite film; utilize silk to rub one surface of polyethylene terephthalate (PET) film to make it electrostatically charged, and then PET film The other surface that is not rubbed is close to the PMMA / graphene composite film floating on the ferric chloride solution, and it is adsorbed on the surface of the PET film by electrostatic action; the PMMA / graphene composite film adsorbed on the surface of the PET film is contacted with deion...

Embodiment 2

[0046] Embodiment 2: The transfer of CVD graphene on the surface of copper foil to the surface of PET is realized by electrostatic interaction.

[0047] The specific steps are similar to those in Example 1, but the final target substrate used is PET film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com