Release film with silicon dioxide film layer and preparation method of release film

A technology of silicon dioxide film and release film, which is applied in the direction of coating, liquid chemical plating, metal material coating process, etc., can solve the problems of non-recyclable and reuse, the decrease of the surface bonding force of contact materials, and the bonding force of insulating boards. drop and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A kind of preparation method of the release film with silicon dioxide film layer, comprises the steps:

[0024] (1) Configure polysilazane solution: the concentration of polysilazane is 1%, and the solvent is organic solvent n-butyl ether;

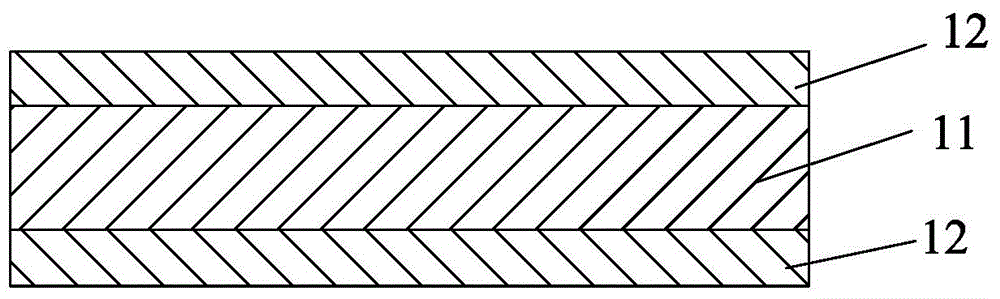

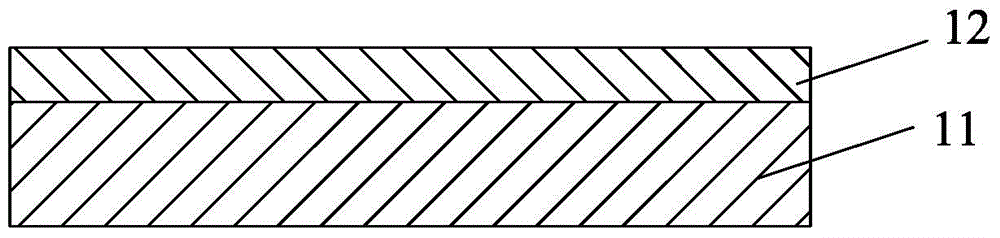

[0025] (2) Coating of base film: coating the above-mentioned polysilazane solution on one side of the 25 micron PET film, driving off the solvent, and drying; then coating the above-mentioned polysilazane solution on the other side of the PET film, driving off the solvent, and drying Dry; polysilazane solution coating dry thickness range: 20 nanometers;

[0026] (3) The product obtained in step (2) is wet heat treated in an oven with a relative humidity of 85% and a temperature of 85°C for 2 hours, and then baked at a temperature of 120-150°C for 2 hours to obtain a double-sided film with a silicon dioxide film layer. Release film.

[0027] Performance Testing:

[0028] The double-sided release film with silicon diox...

Embodiment 2

[0029] Embodiment 2 A kind of preparation method of the release film with silicon dioxide film layer, comprises the steps:

[0030] (1) Configure polysilazane solution: the concentration of polysilazane is 5%, and the solvent is organic solvent n-butyl ether;

[0031] (2) Coating of the base film: coating the above-mentioned polysilazane solution on one side of the 50-micron PET film, driving off the solvent, and drying; then coating the above-mentioned polysilazane solution on the other side of the PET film, driving off the solvent, and drying Dry; polysilazane solution coating dry thickness range: 100 nm;

[0032] (3) The product obtained in step (2) is wet heat treated in an oven with a relative humidity of 85% and a temperature of 85°C for 3 hours, and then baked at a temperature of 120-150°C for 2 hours to obtain a double-sided film with a silicon dioxide film layer. Release film.

[0033] Performance Testing:

[0034] Laminate the double-sided release film with a sili...

Embodiment 3

[0035] Embodiment 3 A kind of preparation method of the release film with silicon dioxide film layer, comprises the steps:

[0036] (1) Configure polysilazane solution: the polysilazane concentration is 10%, and the solvent is organic solvent n-butyl ether;

[0037] (2) Coating of base film: coating the above-mentioned polysilazane solution on one side of the 25 micron PET film, driving off the solvent, and drying; then coating the above-mentioned polysilazane solution on the other side of the PET film, driving off the solvent, and drying Dry; polysilazane solution coating dry thickness range: 200 nm;

[0038] (3) The product obtained in step (2) is wet heat treated in an oven with a relative humidity of 85% and a temperature of 85°C for 3 hours, and then baked at a temperature of 120-150°C for 2 hours to obtain a double-sided film with a silicon dioxide film layer. Release film.

[0039] Performance Testing:

[0040] Laminate the double-sided release film with a silicon di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com