Cyanide-free gold plating electroplate liquid for refractory metal wires

A cyanide-free gold plating and refractory metal technology, applied in the field of metal plating solution, can solve the problems of easy reduction and precipitation of gold ions, narrow range of cathode current density, complicated preparation process, etc., achieves high binding force, simple preparation method, good finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Proportion

[0030] Table 1 is the ratio of each component of the cyanide-free gold plating solution for refractory metal wire in Examples 1-3.

[0031] Table 1 Unit: (gram)

[0032] components

Example 1

Example 2

Example 3

10

20

30

130

140

150

Potassium Citrate

80

100

110

90

100

120

5

10

10

0.5

0.9

1

[0033] 2. Preparation method

[0034] Get each component according to the proportioning described in embodiment 1-3. First measure 700-800ml of deionized water and heat it to 40-60°C, add anhydrous sodium nitrite, stir to dissolve, then add disodium edetate, stir to dissolve, and then add potassium chloride and saccharin in sequence while stirring Sodium and potassium citrate are dissolved together. At this time, the solution should be...

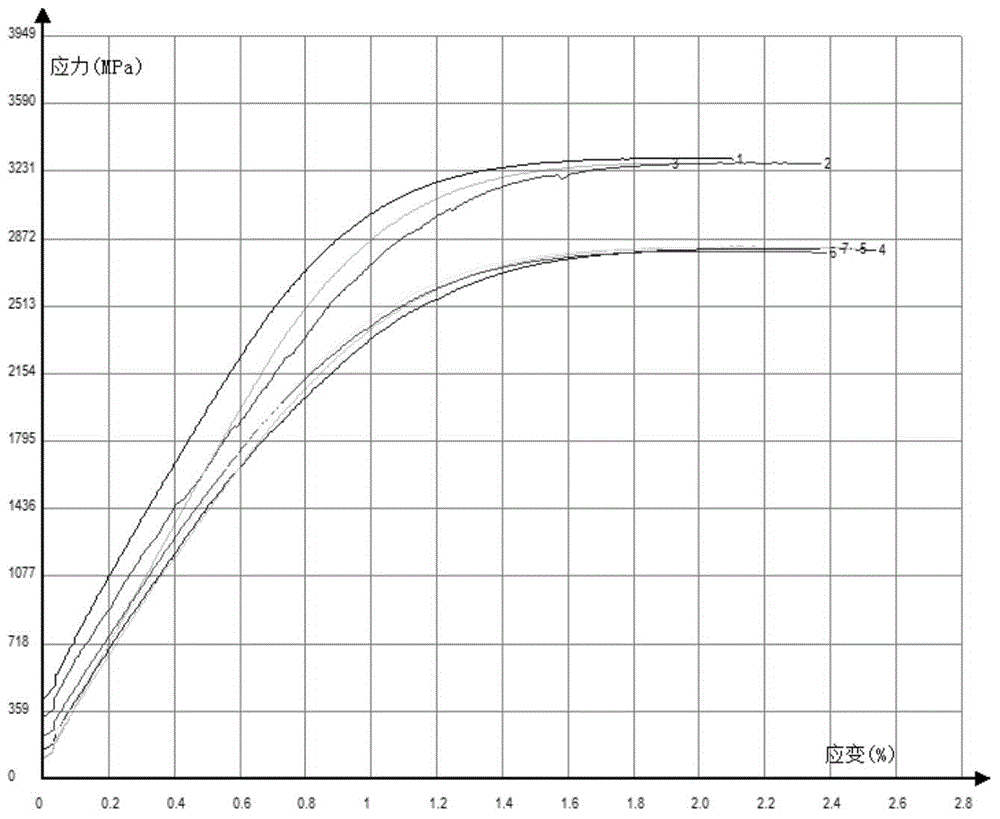

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Pull | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com