A method and application of stripping titanium surface coating by nanotube treatment

A technology of surface coating and nanotubes, which is applied in the preparation of coating cross-section scanning electron microscope samples and electrochemical treatment, which can solve the problems of difficult coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

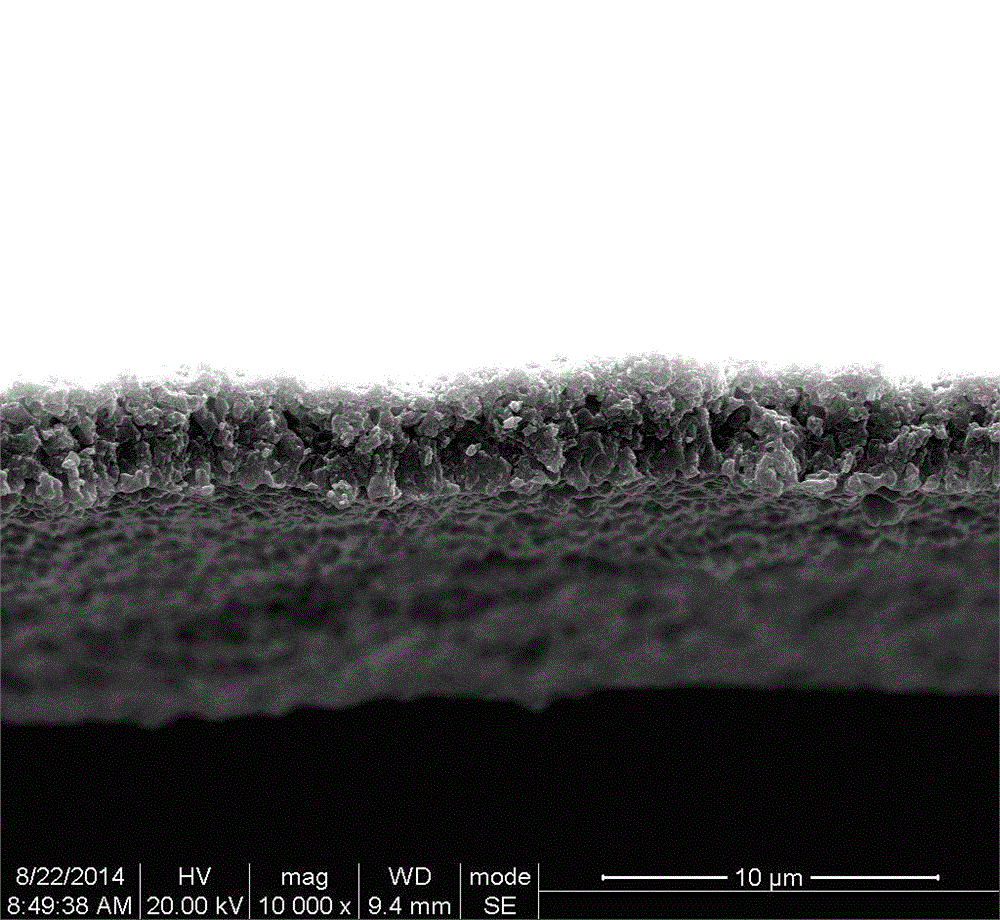

[0026] Sample coating preparation: TA1 pure titanium sheets with a size of 10×10×1 mm were polished and polished with 400, 600, and 800 mesh SiC sandpaper in sequence, and then ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 5 min respectively; Anodizing in constant voltage mode in 1 M sulfuric acid electrolyte, the final voltage was 180V, and kept for 1min after reaching the final voltage. XRD detection shows that the coating on the surface of the sample is a polycrystalline titanium dioxide coating with rutile phase as the main crystal phase and a small amount of anatase phase.

[0027] Then, the treated TC4 pure titanium sheet was ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence, and dried for later use at a drying temperature of 50°C for 1 hour;

[0028] Sample nanotube stripping coating: weigh NH 4 Dissolve 5.2 grams of F in 40 ml of deionized water, mix with 360 ml of glycerin, and stir the solution eve...

Embodiment 2

[0030] Sample coating preparation: TC4 pure titanium sheets with a size of 20×20×2 mm were polished and polished with 400, 600, 800, and 1000 mesh metallographic sandpaper in sequence, and then ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 5 min; anodize in constant voltage mode in 1 M sulfuric acid electrolyte, the final voltage is 150V, and keep for 1min after reaching the final voltage. A brick-red titanium dioxide coating was obtained on the surface of the sample.

[0031] Then the TC4 pure titanium sheet was ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence, and dried for later use at a drying temperature of 60°C for 0.5h;

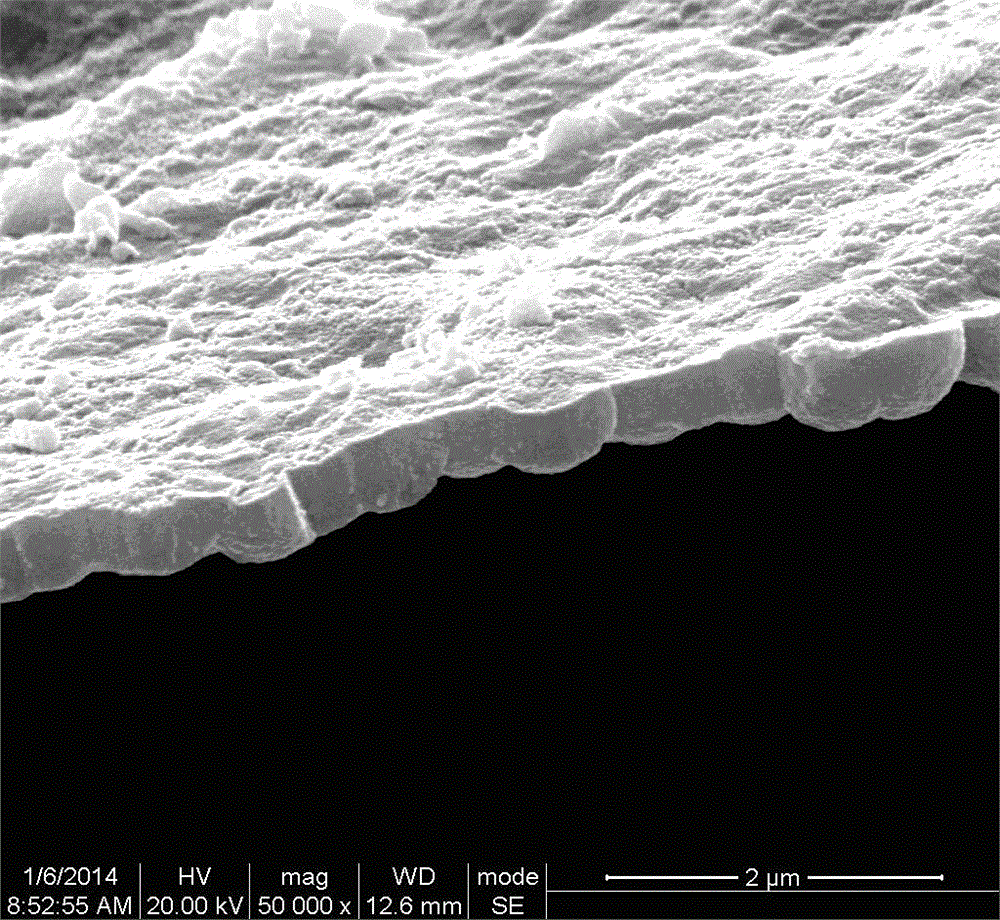

[0032] Sample nanotube stripping coating: weigh NH 4Dissolve 5.2 grams of F in 40 ml of deionized water, mix with 360 ml of glycerin, and stir the solution evenly to obtain an electrolyte solution. Use the titanium alloy sheet as the anode and the titanium foil as the cathode, imme...

Embodiment 3

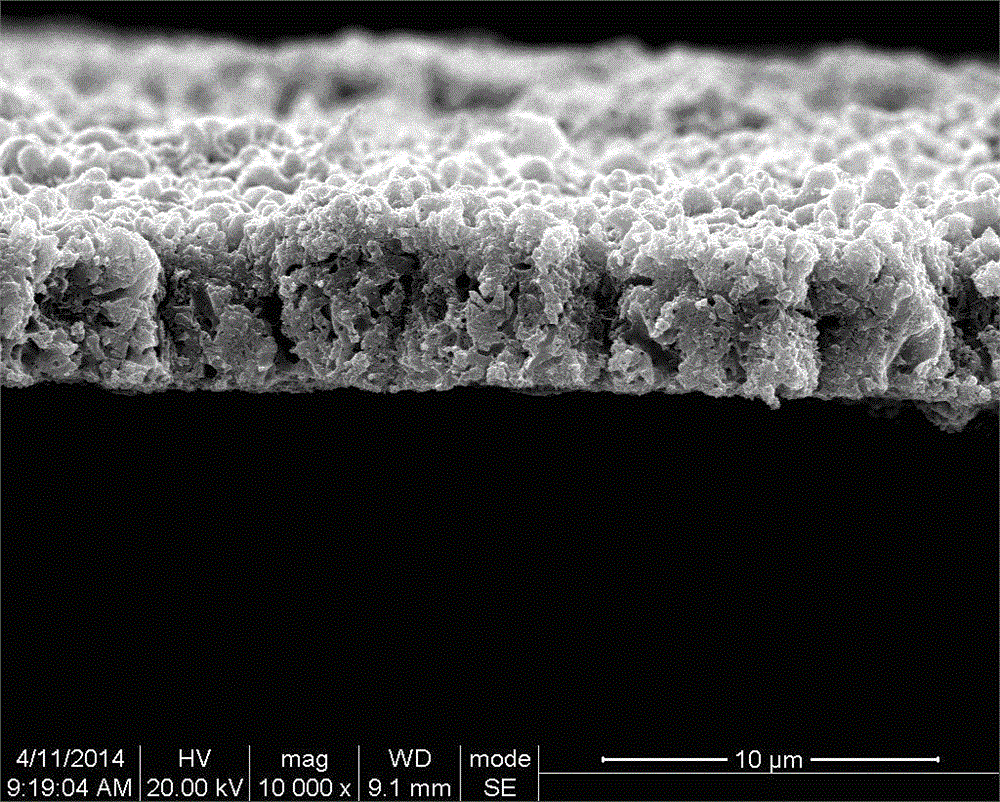

[0034] Sample coating preparation: β-alloy sheets (grades) with a size of 5×5×1 mm were polished and polished with 400, 600, and 800-mesh metallographic sandpaper in turn, and then ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 5 min; anodize in constant voltage mode in 1 M sulfuric acid electrolyte, the final voltage is 150V, and keep for 1min after reaching the final voltage. A titanium dioxide coating was obtained on the surface of the sample.

[0035] Then, the β-alloy sheet was ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence, and dried for later use at a temperature of 55°C for 0.8 hours;

[0036] Sample nanotube stripping coating: weigh NH 4 Dissolve 5.2 grams of F in 40 ml of deionized water, mix with 360 ml of glycerin, and stir the solution evenly to obtain an electrolyte solution. Use the titanium alloy sheet as the anode and the titanium foil as the cathode, immerse the titanium alloy sheet belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com