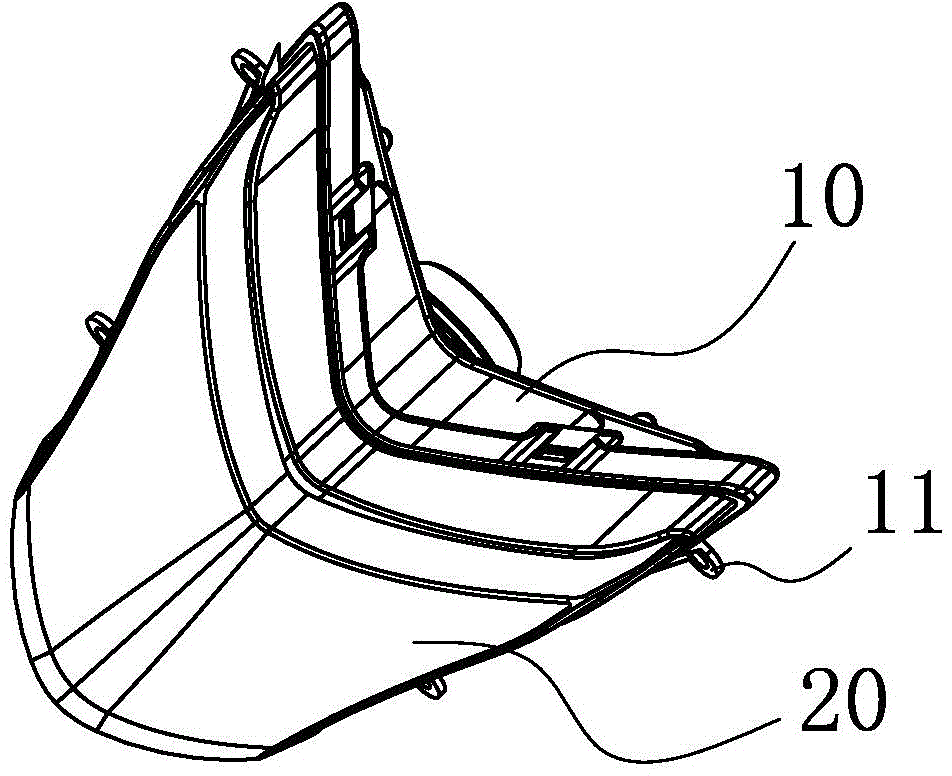

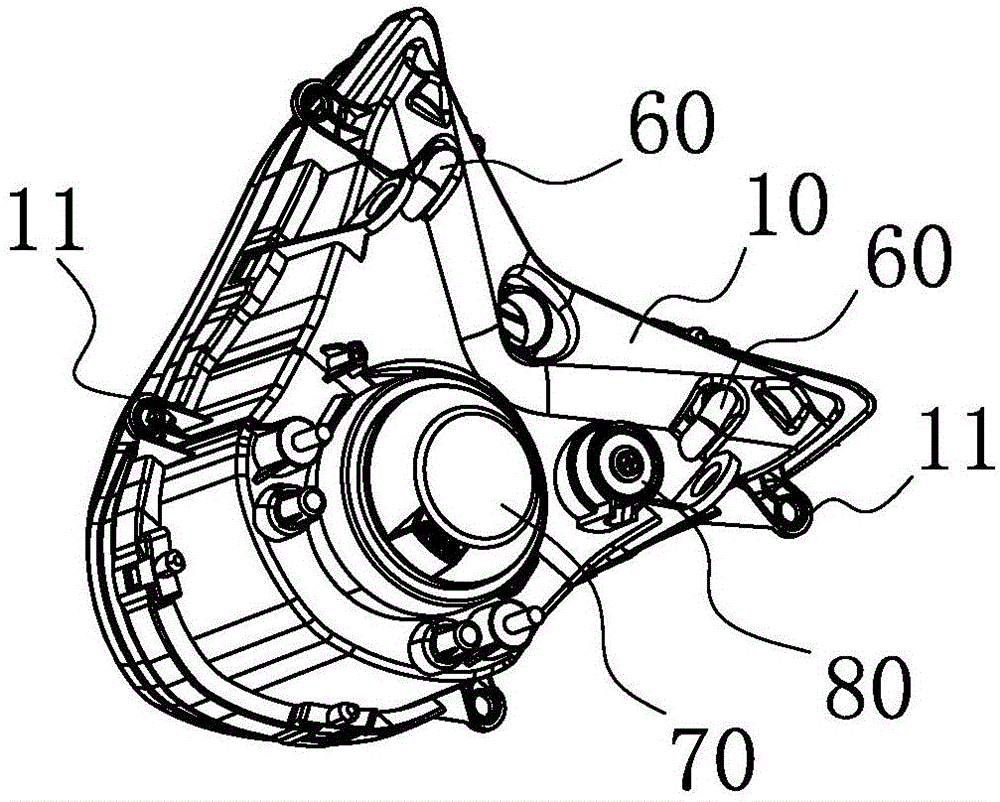

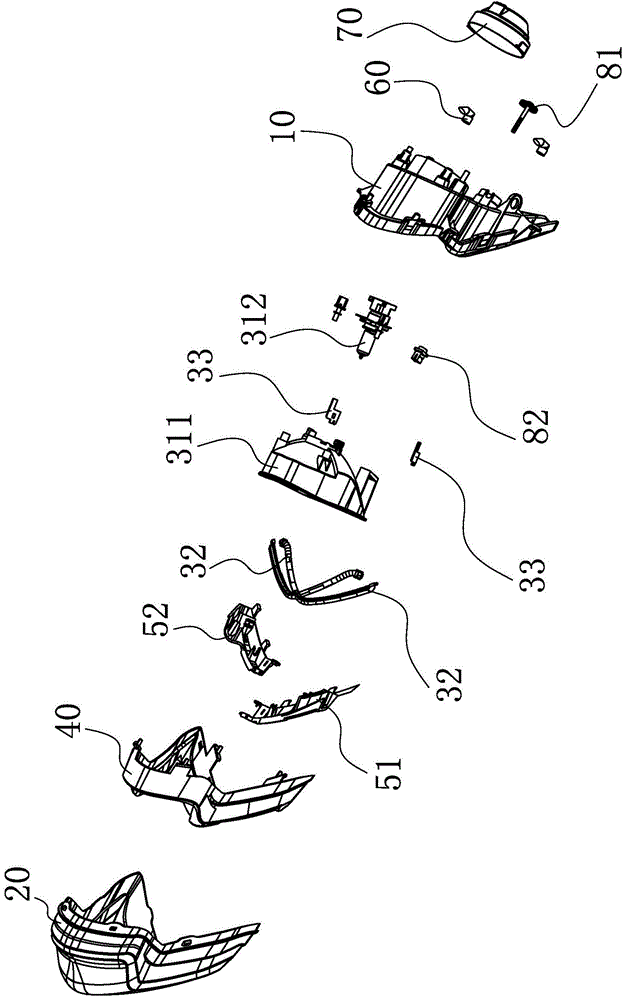

Motorcycle headlamp

A technology for motorcycles and headlights, applied in the direction of headlights, motor vehicles, road vehicles, etc., can solve the problems of affecting the service life of headlights, driving safety, easy burning of LED lights, and unbeautiful headlights, and achieve excellent transparency. , Improve the surface finish, the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Weigh each raw material according to the composition and parts by weight of the composite material used in the reflective strip: polymethyl methacrylate: 50 parts, acrylonitrile-butadiene-styrene copolymer: 25 parts, the surface organic modification with a radius of 60nm Non-toxic nano silica: 3 parts, ultra-fine aluminum oxide particles with a radius of 0.05 μm: 8 parts, glass fibers with a radius of 5 μm: 8 parts, compatibilizer: 8 parts, flame retardant: 4 parts, ultraviolet rays Absorbent: 2 parts, antioxidant: 3 parts; wherein, the average molecular weight of the polymethylmethacrylate is 100,000, the content of MMA is 99wt%, the melt index is 8, and the Izod impact strength is 27J / m ;

[0051] Pour the weighed polymethyl methacrylate and acrylonitrile-butadiene-styrene copolymer into a high-mixer for mixing. After mixing evenly, add other weighed raw materials, stir evenly and heat to obtain a mixed slurry ;

[0052] Inject the mixed slurry prepared above into t...

Embodiment 2

[0054] Weigh each raw material according to the composition and parts by weight of the composite material used in the reflective strip: polymethyl methacrylate: 70 parts, acrylonitrile-butadiene-styrene copolymer: 15 parts, the surface organic modification with a radius of 40nm Non-toxic nano silica: 2 parts, ultra-fine aluminum oxide particles with a radius of 0.02 μm: 5 parts, glass fibers with a radius of 3 μm: 6 parts, compatibilizer: 10 parts, flame retardant: 3 parts, ultraviolet rays Absorbent: 1 part, antioxidant: 1 part; wherein, the average molecular weight of the polymethylmethacrylate is 150,000, the content of MMA is 98wt%, the melt index is 6, and the Izod impact strength is 28J / m ;

[0055] Pour the weighed polymethyl methacrylate and acrylonitrile-butadiene-styrene copolymer into a high-mixer for mixing. After mixing evenly, add other weighed raw materials, stir evenly and heat to obtain a mixed slurry ;

[0056] Pour the mixed slurry prepared above into the ...

Embodiment 3

[0058] Weigh each raw material according to the composition and parts by weight of the composite material used in the reflective strip: polymethyl methacrylate: 30 parts, acrylonitrile-butadiene-styrene copolymer: 30 parts, the surface organic modification with a radius of 80nm Non-toxic nano silica: 3 parts, ultra-fine aluminum oxide particles with a radius of 0.08 μm: 10 parts, glass fibers with a radius of 10 μm: 10 parts, compatibilizer: 10 parts, flame retardant: 5 parts, ultraviolet light Absorbent: 3 parts, antioxidant: 3 parts; wherein, the average molecular weight of the polymethylmethacrylate is 200,000, the content of MMA is 99wt%, the melt index is 10, and the Izod impact strength is 28J / m ;

[0059] Pour the weighed polymethyl methacrylate and acrylonitrile-butadiene-styrene copolymer into a high-mixer for mixing. After mixing evenly, add other weighed raw materials, stir evenly and heat to obtain a mixed slurry ;

[0060] Inject the mixed slurry prepared above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com