Liquid metal medium forced convection experimental loop

A liquid metal, experimental loop technology, applied in measurement devices, instruments, etc., can solve the problems of harsh operating environment of fusion reactor cladding, and achieve the effect of reducing potential harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below by specific embodiment, but this is not limitation of the present invention, those skilled in the art can make various modifications or improvements according to the basic idea of the present invention, but as long as not departing from the basic idea of the present invention, are all within the scope of the present invention.

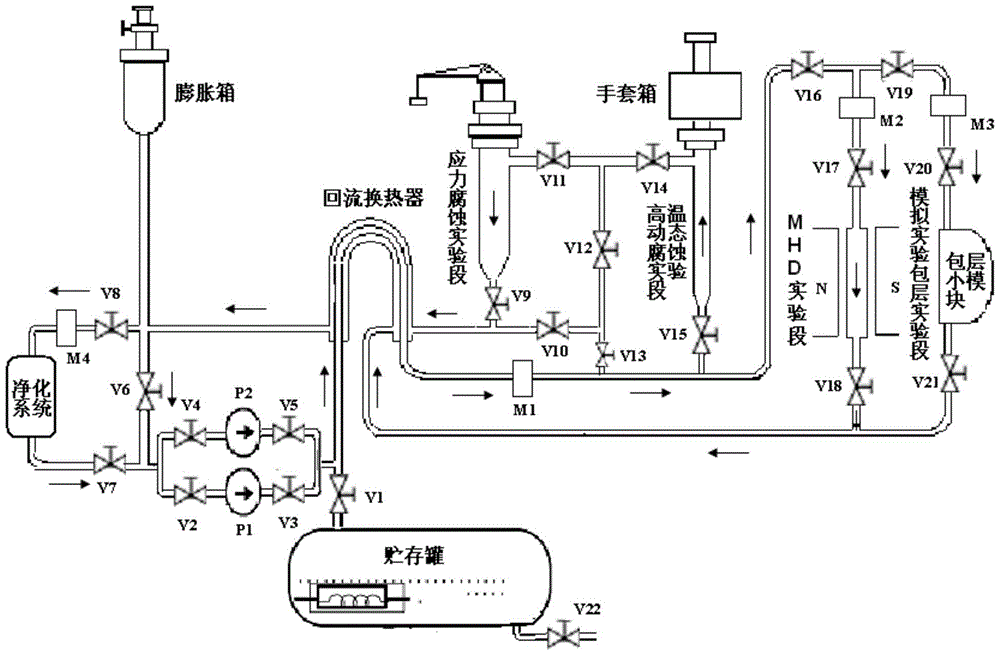

[0034] see figure 1 , liquid metal medium forced convection experimental circuit, its composition mainly includes: a storage tank for storing liquid metal medium, electromagnetic pumps P1 and P2 to drive the flow of liquid metal medium, a purification system for on-line monitoring and purification of impurities, a return heat exchanger, High temperature dynamic corrosion test section, stress corrosion test section, MHD test section (including electromagnet), simulation experiment cladding test section, and related valves V1~V21, flow meters M1, M2, M3, M4, gas system, heating and tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com