Optical fiber sensing device measuring vibration waveform and vibration position simultaneously and sensing method thereof

A vibration waveform and optical fiber sensing technology, which is applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, utilizing wave/particle radiation, etc., can solve the problems of total harmonic distortion, increasing the burden of demodulation system, and high sampling frequency, etc. It achieves the effect of reducing the sampling frequency, superior demodulation effect, and facilitating arraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

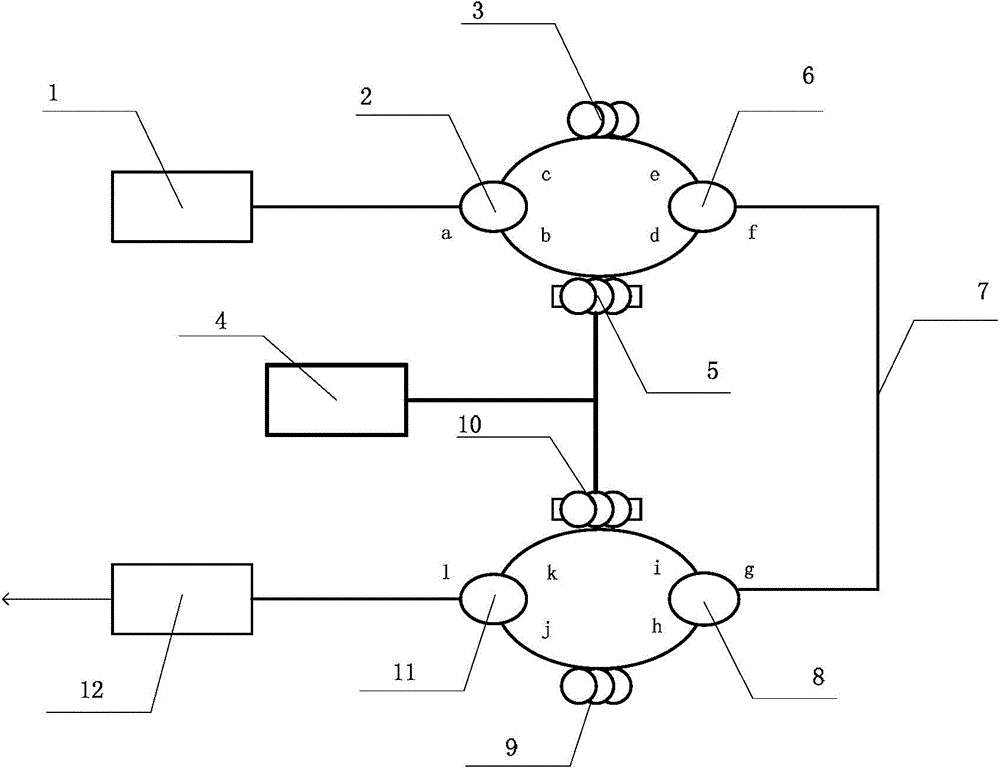

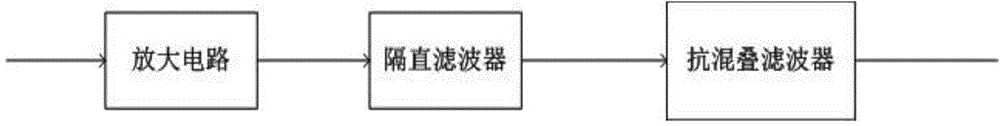

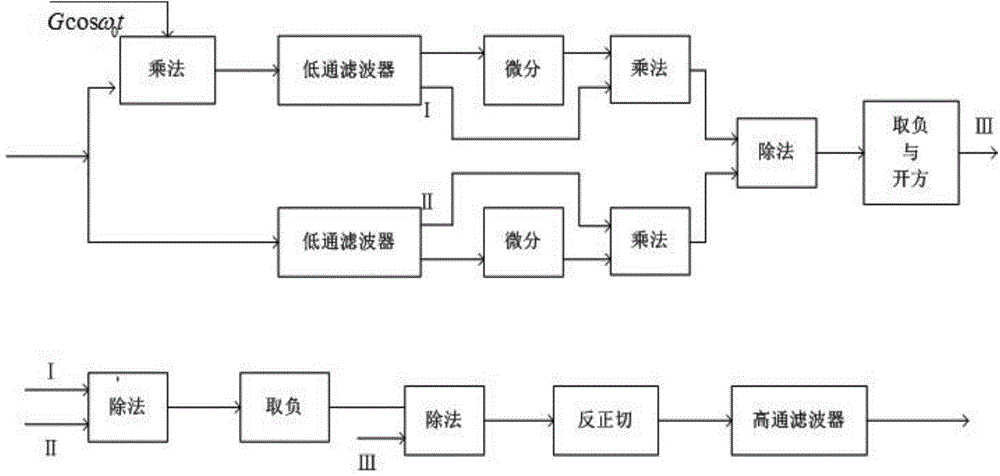

[0034] In this embodiment, the light source is a distributed feedback laser with a wavelength of 1550 nm and a power of 2.3 mw. The two sections of delay fiber are both 25km long, the length of any one of the two Mach-Zehnder interferometers is 8m, and the piezoelectric ceramics wound with 3m optical fibers are placed in the middle of each interference arm. The length of the sensing fiber between two cascaded Mach-Zehnder interferometers is 60km. Assume that the vibration point to be measured is placed 30km away from the first delay fiber. The carrier frequency generated by the signal generator is selected as 1180Hz, the signal sampling frequency in the demodulation circuit is selected as 100KHz, and the signal to be tested is selected as a sine wave with an amplitude of 1 and a frequency of 100Hz. according to Figure 4 It can be concluded that the offset of the waveform on the time axis of the abscissa is 0.00021184, and the relevant parameters set in this embodiment are s...

Embodiment 2

[0036] In this embodiment, the light source is a distributed feedback laser with a wavelength of 1550 nm and a power of 2.3 mw. The two sections of delay fiber are both 25km long, the length of any one of the two Mach-Zehnder interferometers is 8m, and the piezoelectric ceramics wound with 3m optical fibers are placed in the middle of each interference arm. The length of the sensing fiber between two cascaded Mach-Zehnder interferometers is 60km. Assume that the vibration point to be measured is placed 30km away from the first delay fiber. The carrier frequency generated by the signal generator is selected as 1180Hz, the signal sampling frequency in the demodulation circuit is selected as 500KHz, and the signal to be tested is selected as a sine wave with an amplitude of 1 and a frequency of 100Hz. according to Figure 5 It can be concluded that the offset of the waveform on the time axis of the abscissa is 0.00021206, and the relevant parameters set in this embodiment are s...

Embodiment 3

[0038] In this embodiment, the light source is a distributed feedback laser with a wavelength of 1550 nm and a power of 2.3 mw. Both sections of delay fiber are 15km long, and the length of any one interference arm of the two Mach-Zehnder interferometers is 8m. A piezoelectric ceramic wound with a 3m optical fiber is placed in the middle of each interference arm. The length of the sensing fiber between two cascaded Mach-Zehnder interferometers is 60km. Assume that the vibration point to be measured is placed 30km away from the first delay fiber. The carrier frequency generated by the signal generator is selected as 1180Hz, the signal sampling frequency in the demodulation circuit is selected as 500KHz, and the signal to be tested is selected as a sine wave with an amplitude of 1 and a frequency of 100Hz. according to Image 6 It can be concluded that the offset of the waveform on the time axis of the abscissa is 0.00037422, and the relevant parameters set in this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com