A mine pressure similar simulation pneumatic support system and control method

A technology similar to simulation and mine pressure, applied in the direction of non-electric variable control, position/direction control, control/regulation system, etc., can solve the problems of excessive size, complex hydraulic system, high manufacturing, use and maintenance costs, and achieve The air pressure and flow are stable, ensuring the stability of the support and ensuring the effect of precise pressure supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

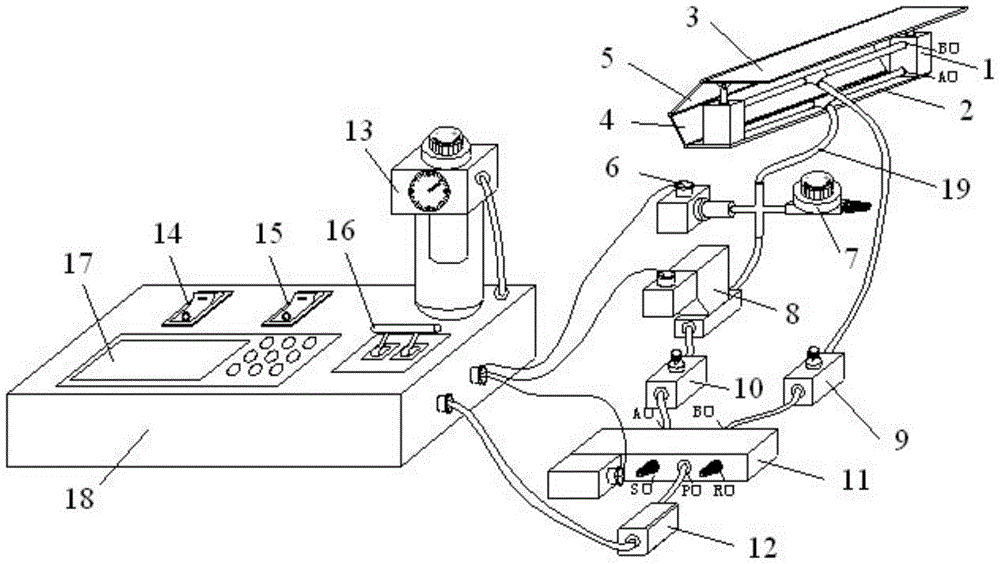

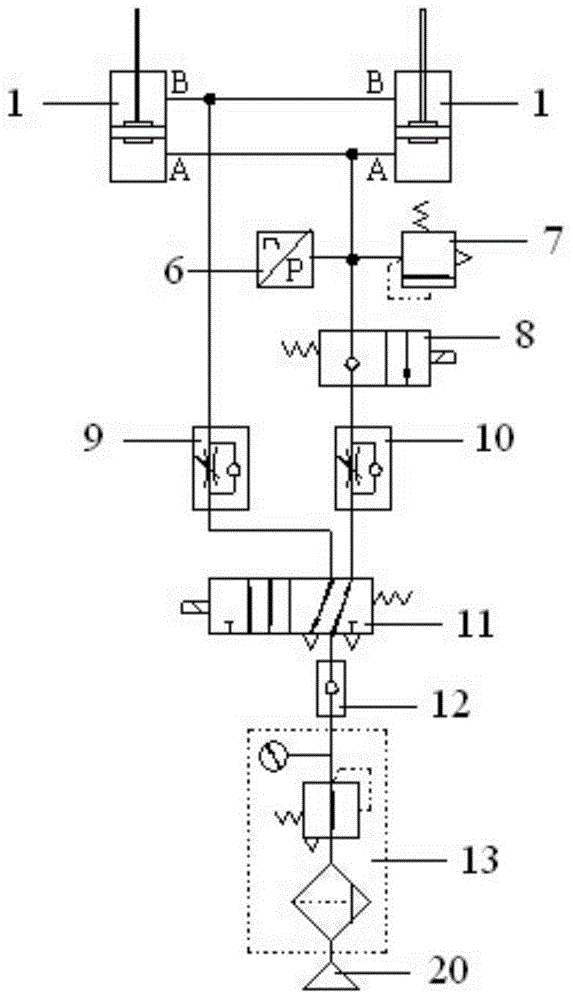

[0039] like figure 1 and figure 2 As shown, the mine pressure similar simulation pneumatic support system of the present invention comprises a support structure, an air circuit structure connected to the support structure and an operation console 18 connected to the air circuit structure; the support structure includes a support base 2, symmetrically located on Two cylinders 1 at both ends of the bracket base 2, the piston rods of the two cylinders 1 are hinged with a bracket top beam 3, a cover beam 5 is arranged behind the bracket top beam 3, and a connecting plate connected with the bracket base 2 is arranged on the cover beam 5 4. The cylinder 1 is a thin cylinder, and the bottoms of the two cylinders 1 are respectively fixedly installed at both ends of the upper plate surface of the support base 2, and the two ends of the lower plate surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com