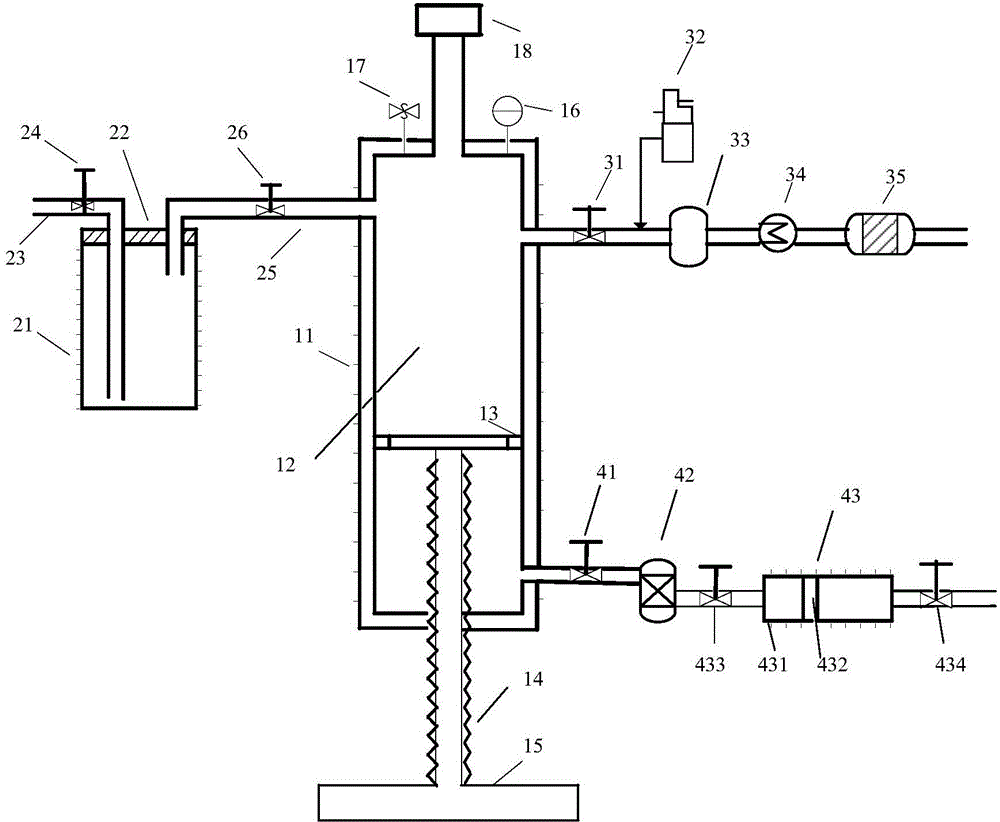

Device and method for oil-gas-water three-phase quantitative and hermetical sampling for indoor experiment

An oil-gas-water and experimental technology, applied in the field of resources and environment, can solve the problems of complicated sampling operation procedures, waste of oil-gas-water, sample waste, etc. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Using the device and method of the present invention to carry out indoor sampling during the one-dimensional physical simulation experiment of microbial flooding, indoor sampling requirements: the total amount of one-time sampling of oil, gas and water is not more than 100ml, the amount of crude oil is not less than 10ml, and the produced water is 50ml and Normal pressure gas volume 10ml, utilize the concrete steps of the present invention as follows:

[0044] (1) Collection of oil-gas-water mixture

[0045] Wet the inner wall of the sampler with surfactant before collecting oil, gas and water. After wetting, rotate the rotating rod to move the oil, gas and water piston of the sampler to the top of the sampler, then connect the sampling connection device, rotate the rotating rod at a uniform speed, and rotate During the process, observe the pressure of the pressure gauge on the top of the sampler. The oil-air-water mixture enters the sampler at a constant speed until th...

Embodiment 2

[0060] Using the device and method of the present invention to carry out indoor sampling during the three-dimensional physical simulation experiment of microbial flooding, indoor sampling requirements: the total amount of one-time sampling of oil, gas and water is not more than 200ml, the amount of crude oil is not less than 30ml, and the produced water is 80ml and Normal pressure gas volume is 50ml, utilizes the concrete steps of the present invention as follows:

[0061] (1) Collection of oil-gas-water mixture

[0062] Wet the inner wall of the sampler with surfactant before collecting oil, gas and water. After wetting, rotate the rotating rod to move the oil, gas and water piston of the sampler to the top of the sampler, then connect the sampling connection device, rotate the rotating rod at a uniform speed, and rotate During the process, observe the pressure of the pressure gauge on the top of the sampler. The oil-air-water mixture enters the sampler at a constant speed un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com