A tsv Interposer structure and its encapsulation method

A packaging method and one-sided technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as cracked silicon holes or insulating layers, low yield, and difficult process control, so as to achieve sufficient insulating layer thickness and improve yield , The effect of reducing the difficulty of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

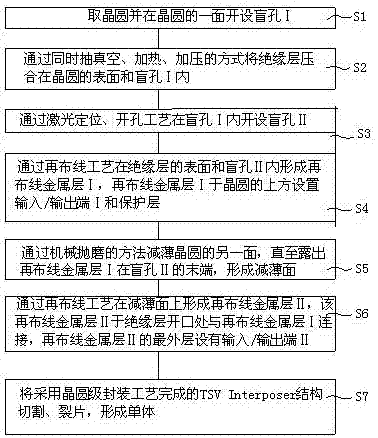

[0056] see figure 1 , the technological process of the encapsulation method of a kind of TSV Interposer structure of the present invention is as follows:

[0057] S1: Take the wafer and open a blind hole I on one side of the wafer;

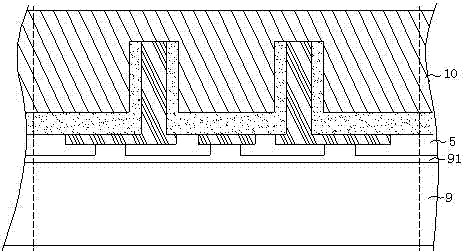

[0058] S2: Pressing the insulating layer on the surface of the wafer and inside the blind hole I by vacuuming, heating, and pressing at the same time;

[0059] S3: Open blind hole II in blind hole I through laser positioning and hole opening process;

[0060] S4: Form the rewiring metal layer I on the surface of the insulating layer and the blind hole II through the rewiring process, and set the input / output terminal I and the protective layer above the wafer on the rewiring metal layer I;

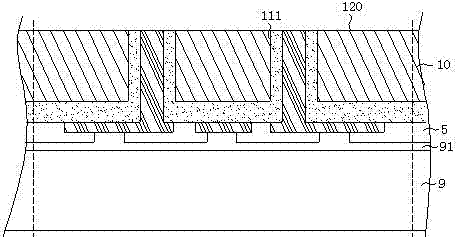

[0061] S5: The other side of the wafer is thinned by mechanical polishing until the rewiring metal layer I is exposed at the end of the blind hole II to form a thinned surface;

[0062] S6: Form the rewiring metal layer II on the thinned surface through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com