Method for producing sectional material of frame of solar photovoltaic module

A solar photovoltaic and production method technology, applied in the direction of photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of lower photoelectric conversion efficiency, solar cell shading, general support effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

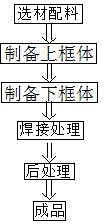

Image

Examples

Embodiment 1

[0018] The specific production method of the frame profile of the solar photovoltaic module mentioned in the present invention is as follows:

[0019] a) Material selection and preparation, the blank is selected from 6063 aluminum alloy sheet, the thickness of the sheet is 2mm, and the length is 2m; among them, the width of the sheet for the upper frame is 50mm, and the width of the sheet for the lower frame is 65mm;

[0020] b) Prepare the upper frame, the processing of the upper frame includes laser hole making and bending treatment; among them, the laser hole making is carried out on a CNC laser cutting machine, the cutting speed is controlled at 100mm / min, the current is 120A, the frequency is 90Hz, the pulse The width is 1.4um; the through-hole structure is a rectangular hole, the distance between the hole edge and the side of the upper frame sheet is about 3mm, the through-hole spacing is about 2.5mm, and the length of the rectangular hole is 20mm; the bending equipment a...

Embodiment 2

[0025] The specific production method of the frame profile of the solar photovoltaic module mentioned in the present invention is as follows:

[0026] a) Material selection and preparation, the blank is selected from 6063A aluminum alloy sheet, the thickness of the sheet is 2.5mm, and the length is 3m; among them, the width of the sheet for the upper frame is 60mm, and the width of the sheet for the lower frame is 80mm;

[0027] b) Prepare the upper frame, the processing of the upper frame includes laser hole making and bending treatment; among them, the laser hole making is carried out on a CNC laser cutting machine, the cutting speed is controlled at 110mm / min, the current is 120A, the frequency is 100Hz, the pulse The width is 1.5um; the through hole is an oblong hole, the distance between the edge of the hole and the side of the upper frame sheet is about 3.5mm, the distance between the through holes is about 3mm, and the length of the oblong hole is 22mm; the bending equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com