Model-based design device and method for double closed-loop three-level inverter system

A three-level inverter, model design technology, applied in the output power conversion device, calculation, electrical components and other directions, can solve the problems of low manual programming efficiency, high correction cost, system development failure, etc. Test cycle, convenient automation, and the effect of reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

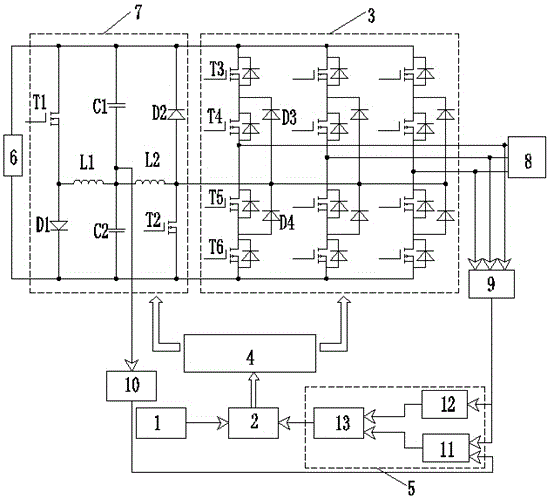

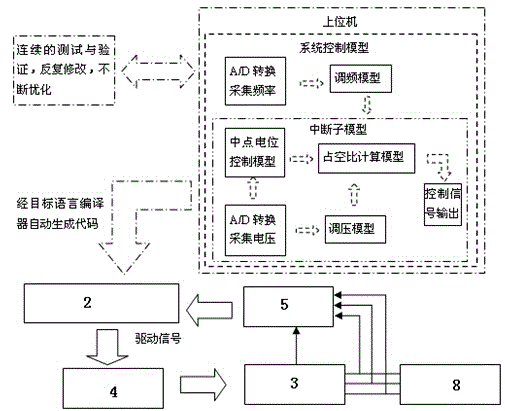

[0022] The specific embodiment of the present invention is illustrated in conjunction with the accompanying drawings; a device based on model design of a double closed-loop three-level inverter system, including a host computer 1, an embedded chip main control unit 2, an inverter main circuit 3, a drive module 4, Detection and conditioning module 5, DC stabilized power supply 6, midpoint potential control circuit 7, load 8, first sensor 9 and second sensor 10, said detection and conditioning module 5 includes voltage transformer 11, effective value detection chip 12 and signal The output terminal of the DC stabilized power supply 6 described in the conditioning module 13 is connected to the midpoint potential control circuit 7, the output terminal of the midpoint potential control circuit 7 is connected to the input terminal of the inverter main circuit 3, and the inverter main circuit 3 The output terminals of the first sensor 9 are respectively connected to the load 8 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com