Inorganic heat-insulating mortar and preparation method thereof

A technology of inorganic thermal insulation mortar and water retention agent, which is applied in the field of building materials, can solve the problems of not obvious advantages in thermal insulation performance and high thermal conductivity of cement, and achieve the effects of high strength, good water resistance and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

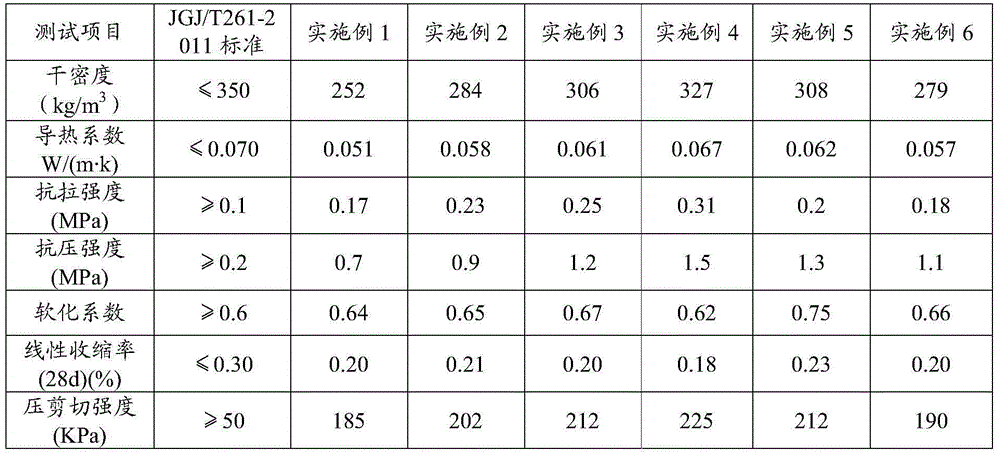

Examples

preparation example Construction

[0032] In the present invention, the fluorogypsum powder is pulverized fluorogypsum. The preparation method of described fluorogypsum powder preferably comprises the following steps:

[0033] The fluorine gypsum is neutralized, aged and ground in sequence to obtain fluorine gypsum powder.

[0034] The present invention has no special limitation on the source of the fluorine gypsum, for example, waste residue fluorine gypsum generated in the process of producing hydrogen fluoride or fluoride salt by fluorine chemical enterprises can be used. In the present invention, before neutralizing the fluorogypsum, the fluorogypsum is preferably cooled. After the cooling is completed, the present invention neutralizes the cooled fluorogypsum. The present invention has no special limitation on the neutralization method, and the technical scheme of adding lime and stirring well known to those skilled in the art can be adopted; the addition of the lime The amount is preferably 0.4 wt% to 0...

Embodiment 1

[0081] (1) Fluorogypsum powder is prepared from the waste residue fluorogypsum discharged from Hunan Nonferrous Xiangxiang Fluorochemical Co., Ltd., and the fluorogypsum is anhydrous fluorogypsum with a calcium sulfate content of more than 90%. The temperature of the freshly discharged fluorogypsum is above 200°C, which is acidic. The fluorogypsum is naturally stacked and cooled, and 0.5wt% of lime is added to stir evenly. After aging for 3 days, it is ground by a ball mill to obtain a fineness of 200-mesh 300 mesh fluorine gypsum powder.

[0082] (2) 40kg of fluorine gypsum powder obtained in step (1), 16kg of superfine slag powder, 5.2kg of ordinary Portland cement of 42.5 grade, 1.5kg of quicklime, 0.2kg of industrial grade Na 2 SO 4 , 1.2kg industrial grade K 2 SO 4 , 0.5kg24-88 type polyvinyl alcohol micropowder, 0.3kg hydroxypropyl methylcellulose and 0.1kgRN31 type air-entraining agent are added in the ball mill, after fully stirring, grind to obtain a mixture with a...

Embodiment 2

[0085] (1) Fluorogypsum powder is prepared from the waste residue fluorogypsum discharged from Hunan Nonferrous Xiangxiang Fluorochemical Co., Ltd., and the fluorogypsum is anhydrous fluorogypsum with a calcium sulfate content of more than 90%. The temperature of the freshly discharged fluorogypsum is above 200°C, which is acidic. The fluorogypsum is naturally stacked and cooled, and 0.5wt% of lime is added to stir evenly. After aging for 3 days, it is ground by a ball mill to obtain a fineness of 200-mesh 300 mesh fluorine gypsum powder.

[0086] (2) The fluorine gypsum powder that 50kg step (1) obtains, 12kg superfine slag powder, 5kg42.5 ordinary Portland cement, 1.6kg quicklime, 0.2kg industrial grade Na 2 SO 4 , 0.6kg industrial grade K 2 SO 4 , 0.3kg24-88 type polyvinyl alcohol micropowder, 0.2kg hydroxypropyl methylcellulose and 0.1kgRN31 type air-entraining agent are added in the ball mill, after fully stirring, grind to obtain a mixture with a fineness of 200 mesh....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com