Composite material for preparing textile dyeing tube

A composite material and dyeing tube technology, which is applied in the field of composite materials for preparing dyeing tubes for textiles, can solve problems such as troublesomeness and insufficient hardness of dyeing tubes, and achieve the effects of good toughness, excellent physical and mechanical properties, and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in combination with specific implementation methods.

[0015] 10 parts of PET resin; 10 parts of ASA resin; 1-6 parts of matting masterbatch; 1-3 parts of titanium dioxide; 1-2 parts of rosin; 0-1.5 parts of antioxidant; share.

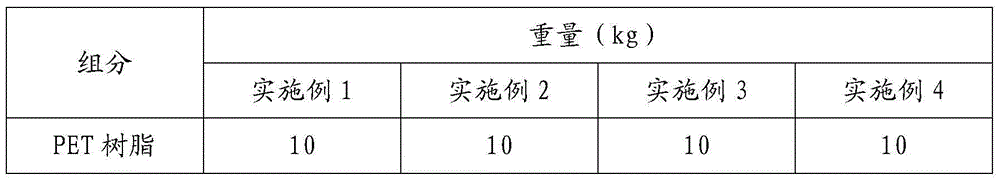

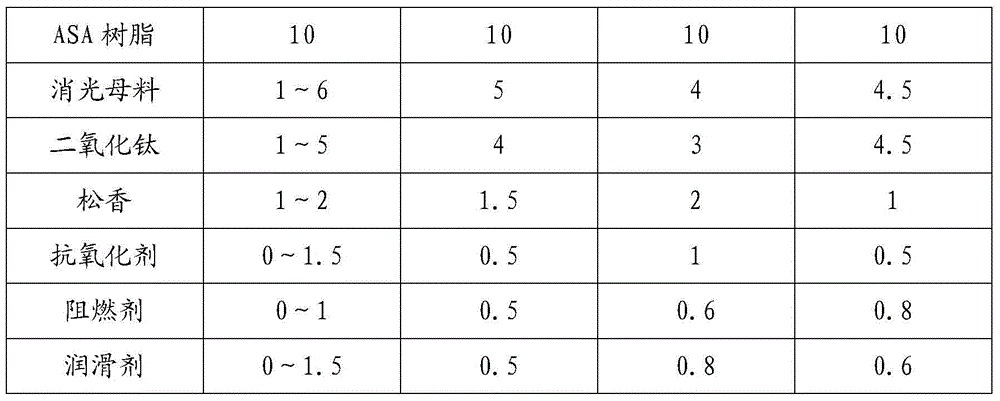

[0016] The following table is the weight proportion of each embodiment.

[0017]

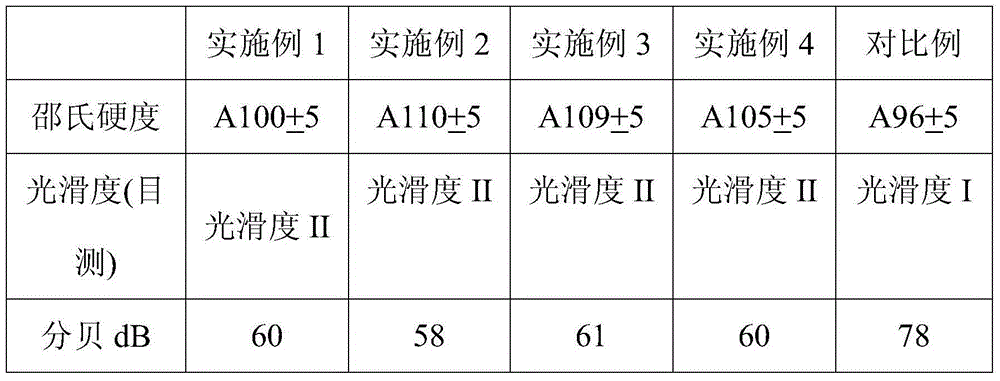

[0018]

[0019] In the above-mentioned embodiments, the components of the matting masterbatch include mineral powder and polyolefin matrix material, and the mass percentage of the mineral powder in the matting masterbatch is controlled at about 45%-65%. The mineral powder can be silica.

[0020] During the preparation process, the above-mentioned components are weighed according to the proportion and then put into a high-speed mixer and mixed evenly. The titanium dioxide is pre-heated to melt, and then sent into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com