Method for producing isoprene by in vitro enzymatic reaction and application of isoprene

A kind of isoprene, in vitro enzyme technology, applied in the field of bioengineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

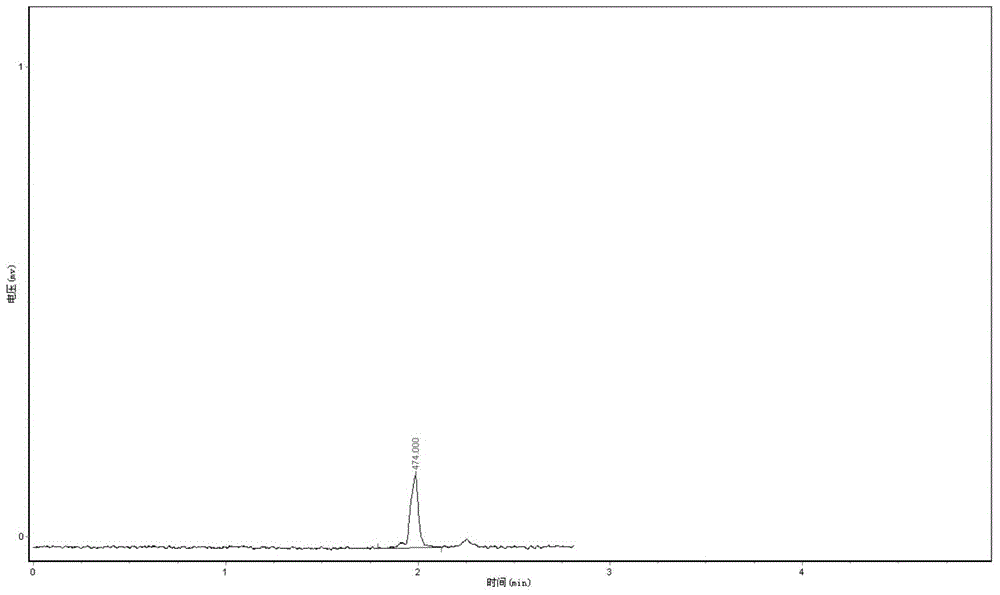

[0047] (1) Take 100ml of E. coli culture solution expressing the above five enzymes at 7000rpm, centrifuge at 4°C for 5min, discard the supernatant, wash twice with 50mM, pH 7.4 phosphate buffer, and finally use 5ml phosphate buffer to resuspend; then use Ultrasonic crusher (22kHz, 150w), after crushing, centrifuge at 15000rpm at 4°C for 5min, separate the supernatant from the precipitate, keep the supernatant, add 10% glycerol, and measure the protein content according to the kit method.

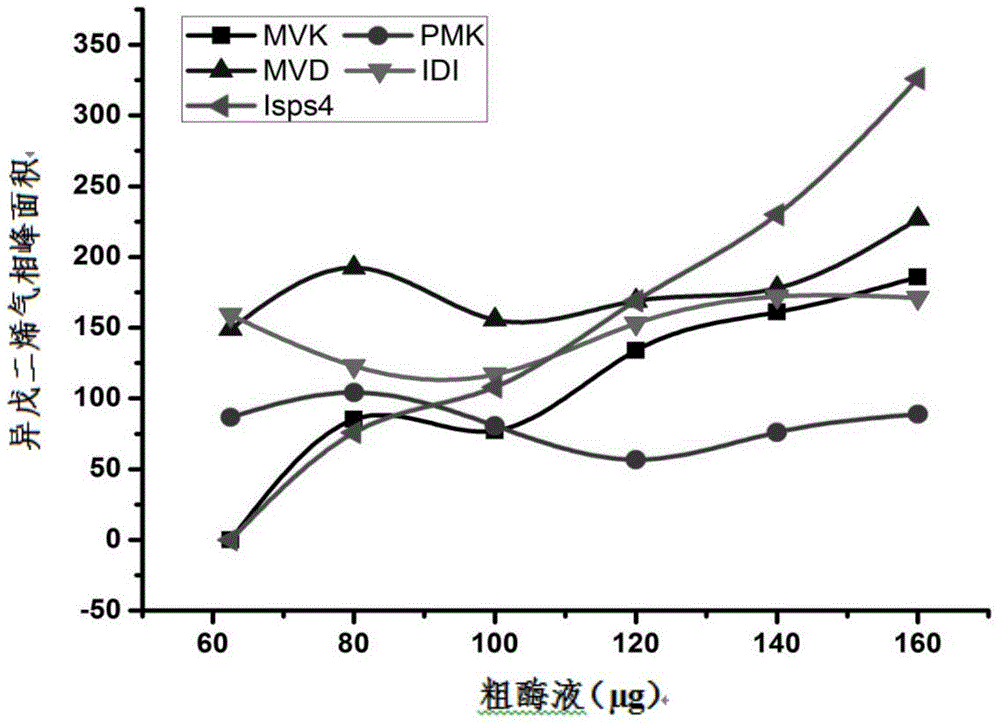

[0048] (2) In order to investigate the action strength of each enzyme in the catalytic reaction, the obtained phosphomevalonate kinase, mevalonate pyrophosphate decarboxylase, isopentenyl pyrophosphate isomerase, isopentyl The concentration of diene synthase was fixed at 120 μg / L, and only the amount of mevalonase was changed. 160μg / L, do six reactions, the final reaction system is: 50mM phosphate buffer, 4mM ATP, 30mM KCl, 8mM MgCl2, 0.2mM MnCl2, 0.01mM ZnSO4, 4mM β-mercaptoethanol, 2.5mM ...

Embodiment 2

[0051] (1) Take 100ml of E. coli culture solution expressing the above five enzymes at 7000rpm, centrifuge at 4°C for 5min, discard the supernatant, wash twice with 50mM, pH 7.4 phosphate buffer, and finally use 5ml phosphate buffer to resuspend; then use Ultrasonic crusher (22kHz, 150w), after crushing, centrifuge at 15000rpm at 4°C for 5min, separate the supernatant from the precipitate, keep the supernatant, add 10% glycerol, and measure the protein content according to the kit method.

[0052] (2) In order to investigate the action strength of each enzyme in the catalytic reaction, the mevalonate kinase, mevalonate pyrophosphate decarboxylase, isopentenyl pyrophosphate isomerase, and isopentyl diphosphate obtained in step (1) were The concentration of ene synthase was fixed at 120 μg / L, and only the amount of phosphomevalonase was changed, the concentrations were 0 μg / L, 62.5 μg / L, 80 μg / L, 100 μg / L, 120 μg / L, 140 μg / L, 160μg / L, do six reactions, the final reaction system ...

Embodiment 3

[0055] (1) Take 100ml of E. coli culture solution expressing the above five enzymes at 7000rpm, centrifuge at 4°C for 5min, discard the supernatant, wash twice with 50mM, pH 7.4 phosphate buffer, and finally use 5ml phosphate buffer to resuspend; then use Ultrasonic crusher (22kHz, 150w), after crushing, centrifuge at 15000rpm at 4°C for 5min, separate the supernatant from the precipitate, keep the supernatant, add 10% glycerol, and measure the protein content according to the kit method.

[0056] (2) In order to investigate the action strength of each enzyme in the catalytic reaction, the mevalonate kinase, phosphomevalonate kinase, isopentenyl pyrophosphate isomerase and isoprene obtained in step (1) were synthesized The enzyme concentration was fixed at 120 μg / L, and only the amount of mevalonate pyrophosphate decarboxylase was changed. 160μg / L, do six reactions, the final reaction system is: 50mM phosphate buffer, 4mM ATP, 30mM KCl, 8mM MgCl2, 0.2mM MnCl2, 0.01mM ZnSO4, 4m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com